NaN / 0

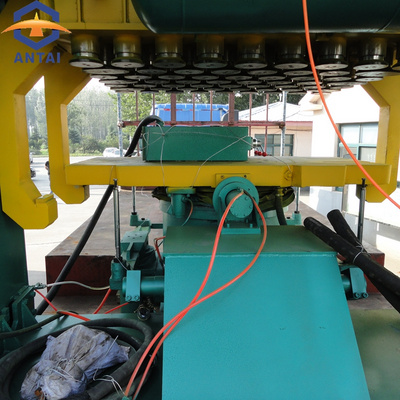

Cast iron manhole cover foundry green sand molding machine

Get Latest Price

US$ 20000

≥1 Sets

Quick Details

Place of Origin:

Shandong, China

Machine Type:

Automatic

Brand Name:

Antai

Voltage:

380V/415V/440V

Product Details

Iron casting manhole cover foundry green sand molding machine

1. Usage

The machine is generally used for foundry casting workshop, mechanical production lines or semi-mechanical production lines.

2. Characteristics

A. Pneumatic multi-contact compaction is adopted to optimize the design of the machine, without oil leakage; m oderate specific pressure, no special requirements for sand, more compaction contacts (48 pcs ), suitable for complex moulding.

B. High pressure compaction, the multi-contacts compacts sand molding,

and vibrate with working table(separated from machine frame, and frame without vibration). Therefore, good vibration effect, high hardness and uniform sand moulding(average hardness 85~90 , B type hardness tester), the sand consumption can be as small as 20~30 mm, the compaction ratio is up to 4.2, and the vertical surface hardness of the mold cavity can still reach above HB80.

C. The machine adopts the spring micro-vibration compaction mechanism , large compaction cylinder diameter, high pressure strength,compacted and even sand moldings, it can guarantee quality of casting.The mold stripping structure adopts way of air oil pressure, the mold stripping adopts connecting rod, the synchronous shaft structure, the pressure oil speed regulation, good mold stripping synchronization, realizes the stable drawing by the two lifting cylinders, the

connecting rod, and the synchronous shaft. Simple pneumatic pipeline, easy and flexible operation, convenient operation, The machine adopts the spring fully cushioned pneumatic micro-vibration mechanism, no special foundation requirement.

D. The machine increases the stroke of the compaction cylinder, adopts multiple mechanisms to increase the pressure strength, and at the same time, it can pressurize and vibrate according to actual need, so that the elevation and plane hardness of the sand type (including type of complex sand moulding ) are compact and even. Convenient operation and high productivity.

3. Main technical specifications

| No. | Item | Remark |

| 1 | Inner size of sand moulding flask | 1000mm*800mm*350mm |

| 2 | Size of working table | 1200mm*800mm |

| 3 | Normal working pressure | 0.5Mpa |

| 4 | Shock force(0.5Mpa pressure) | 3000kfg |

| 5 | Compaction ratio pressure | 4.2kg/cm 2 |

| 6 | Vibrating cylinder diameter | φ350mm |

| 7 | Compaction distance | 260mm |

| 8 | Mould stripping distance | 350mm |

| 9 | Quantity of multi-contacts | 48pcs |

| 10 | Compaction distance of multi-contacts | 270mm |

| 11 | Multi-contacts compaction ratio(0.5Mpa) | 4.2kfg/cm 2 |

| 12 | Max distance from multi-contacts to working table | 530mm |

| 13 | Free air consumption | 1.0m 3 /half mould |

| 14 | Productivity | 40-60 half moulds/h |

| 15 | Total weight | 11,000kgs |

If the machine is not suitable for your workpiece, please tell us the following information:

1) What kind of workpiece will you clean?

2) The size of workpieces(length, width and height of maximum workpiece,Length, width and height of minimum workpiece?)

3) How many the weight of maximum and minimum workpiece?

4) Please tell us your requirement cleaning efficiency?

According to your infomation, the most suitable machines will be designed for your workpieces.

ANY OTHER QUESTIONS PLS CONTRACT WITH ME FREELY.

Hot Searches