NaN / 0

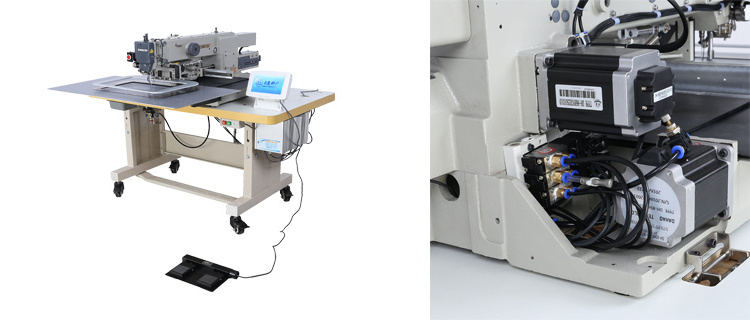

promotional heavy duty industrial sewing machine for glove

Get Latest Price

US$ 3500

≥1 Sets

US$ 2900

≥10 Sets

Quick Details

Type:

Industrial Sewing Machine

Max. Sewing Thickness:

Thin, Medium, thick

Stitch Length:

12.7mm

Feed Mechanism:

Manual

Product Details

Product Description

1. Single machine arm auto transmission;

2. Neat and beautiful stitches originate from thoughtful design, easy to meet exporting requirement of high quality;

3. Advanced pattern software system

(Dahao tech), powerful pattern editing function, convenient for customers DIY design patterns quickly;

4. Extra function customized retrofitting available(OEM/OD

M).

Pattern sewing machine 300x200mm auto sewing

Design Features

1.X, Y axis transmission sensor

Can quickly detect the machine arm transmission range, to control the raw material pattern within the sewing range.

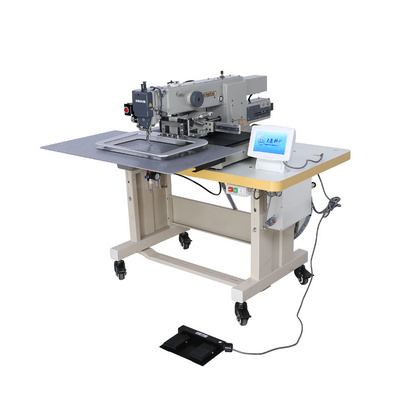

2. Effective oil supply

Supply oil slowly when working, prevent high wastage during production process; indicator shows the oiling situation for daily maintenance.

3.Transmission gear and rack

Auto transmission system set workers free from moving the material to sew, just need to handle the material into the pattern panel, get the job done by pressing one button.

4.Big rotary hook & auto cutting

Twice big hook and shuttle means half time in pause and changing bottom thread, improve the production efficiency. As per pattern design, when rotary knife move to the fixed knife, the thread will be cut automatically.

5.Stepper motor for X, Y axis transmission

Unlike sewing head using direct drive servo motor, the X,Y axis transmission uses stepper motor, avoid any interruption of voltage or current change, stop moving exactly when needed.

6.Full touch screen and simple interface

Six operating languages: Chinese, English, Japanese, Korean, Burmese, Turkish.

Colour graphics display, easy to operate and edit design, we have videos to teach people how to sew.

Production Process

Production takes time and effort.

From pieces of raw material, we clean, assemble, grind, etc., step by step and finally the our technology become part of the machine.

Before the machine serves the users, so many works had been done by our engineers, workers and QCs.

With such hard work, quality of our machines is filled with confidence and pride.

Retrofitted Solution

Side-sliding presser foot retrofit

Application: to sew tiny trademarks and logos automatically and quickly( X,Y axis size of XC-3020R:300*200mm)

As above pictures showing how it works step by step:

1. Placing the logos into the pattern sewing hole;

2. Make sure the logos placing in the right position;

3. The side-sliding presser foot moves in, presses against the logo then starts sewing according to the pattern design;

4. When sewing stitch goes near the presser feet, the press feet resets, moves away to make room for full lockstitch.

2. Make sure the logos placing in the right position;

3. The side-sliding presser foot moves in, presses against the logo then starts sewing according to the pattern design;

4. When sewing stitch goes near the presser feet, the press feet resets, moves away to make room for full lockstitch.

180° turn-over U shape presser foot retrofit

Application: to sew small trademarks and logos automatically and quickly( X,Y axis size of XC-3020R:300*200mm)

As above pictures showing how it works step by step:

1. Pressing the material under the pattern panel steadily, and start to sew within the U shape area;

2. Continue to sew till the edge of U shape presser foot;

3. The U shape presser foot turns over 180° to the other side, allows the needle to finish sewing the full pattern;

4. After presser foot lifting, the U shape presser foot also resets and waits for the next round.

Our Company

Our mission: to serve customers

* Great teamwork in pre-sales and after-sales.

* Excellent showroom for on-site check.

* OEM/ODM service

* Patent protection.

* Distribution channel.

Our vision: focus on quality & technology

* 18 years' effort on improving quality and technology.

* Large amount of R&D investment in sewing machine idustry.

* Great attention on feedback concerning quality and technology.

* Engineering and merchanical team work together to handle technology issues.

Xingchi Provide sewing quipments including whole set or spare parts of sewing machine:

* computer sewing machine series

* 341cylinder bed series

* debburring machine for box & handbag

* cylinder bed series

* computer automation series

* post bed series

* lockstitch zigzag sewing machine series

* special function series

* double needles sewing machine series

* flat bed series

* lockstitch sewing machine with top and bottom

* post bed bottom feed sewing machine

* post bed series

* overlock sewing machine series

* leather skiving machine

* automatic plastic folding machine series

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal, use and fix the machine with remote visual support.

* Engineers available to service machinery overseas in Ha Noi, Hai Phong of Viet Nam, and Phom Penh of Myanmar.

* Overseas distributor/partners also provide engineer support in the near future.

Packing & Delivery

Related Products

Garment Application

Tradmark/LOGO

Auto Stitch

Shoes Application

Upper/Sole/Insole Pattern Sewing

Glove Applicaiton

Leather/Safety Glove Pattern Stitch

Hot Searches