NaN / 0

High density close cell Cross Linked Polyethylene Foam / Polyethylene Foam sheet

Get Latest Price

US$ 3

≥1 Cubic meter

US$ 2

≥2 Cubic meter

US$ 1

≥10 Cubic meter

Quick Details

Place of Origin:

Zhejiang, China

Brand Name:

Mylon

Model Number:

M-PE foam-04

Thickness:

1mm-100mm

Product Details

High density close cell Cross Linked Polyethylene Foam / Polyethylene Foam sheet

PE foam sheet features:

(1)Water durable: Closed-cell foam, non-water-absorbing, moisture-proof.

(2) Rot resistant: Seawater, oil, acid and alkali durable; antibacterial, safe, odorless and non-polluting.

(3) Easy processing: Continuous; easy hot-press shaping, casting, gluing and joining.

(4) Shockproof :Good flexibility and anti-hardening; excellent shockproof and cushion capability.

(5) Heat preservation: Excellent heat insulation, anti-cold, non-frosting and insulation enduring capabilities.

(6) Sound insulation: Closed-cell foam, good sound insulation capability.

(7) Application: Widely used in puzzles, resting cushions, children's toys , medium and shoes material ,compound floorboard ,craftwork decoration sand ,shoe material , packing lining ,curtain wall and so on .

- Closed Cell

- Very Lightweight

- Non-abrasive

- Easy to fabricate

- Non-dusting

- Superb strength and tear resistance

- Excellent shock absorption & vibration dampening properties

- Flexibility

- Impervious to mildew, mold, rot, and bacteria

- Resistant to water, chemicals, solvents & grease

- CFC free

- Recyclable

- Odorless

- Excellent buoyancy

- Very cost-effective

- Excellent thermal insulation properties

PE Foam Applications

Correctly foamed polyethylene has a structure of small regular cells. Due to this factor it has a high heat and sound insulation capacity and excellent shock absorbing capability. The building-, packaging- and automotive industry and

the producers of sports- and leisure articles are happy to utilise these excellent properties. PE foams can be produced

in any colour desired. Children highly appreciate the colourful fun toys for swimming pools and three-dimensional puzzles. Their parents and grand parents are more charmed by the comfort of garden seat cushions and knee protectors.

As a result of the excellent heat insulation, PE foams are used for the insulation of central heating pipes. For the same reason and also for the sound absorption it is used on concrete floors under tiles- or parquet floors. Again for it sound absorption and heat insulation PE foam sheets are used in buildings as roof insulation, which is growing in popularity

over the last years; so in homes and offices, PE is showing it face more and more.

Also in the packaging industry we see the use of PE foam. Due to the high shock absorbing capability, fragile glasswork, TV set, audio sets and printers are wrapped in PE foam sheet and in preformed foam blocks.

The producers of sports- and leisure articles have also noticed that PE foam easily intercepts the blows. (Ice) Hockey players, ice- and roller skaters and skiers are enjoying the comfort of knee-, shin-, elbow- and head protectors to increase their resilience. On top of that we find PE foam in swimming pools, in childrens playgrounds, on camping sites, etc where it is used in surf boards, toys, puzzles and camping mats.

The car interior is also covered with a PE foam layer. The automotive industry heats the foamed PE sheets and moulds them in the desired shape to cover the dashboards, door panels, consoles, boot interiors and handgrips. Finally a part of the PE foam in cars is unvisible?as it is used as double-sided adhesive tapes for the fixing of spoilers, rear and front lights, body side protective mouldings, emblems and mirrors.

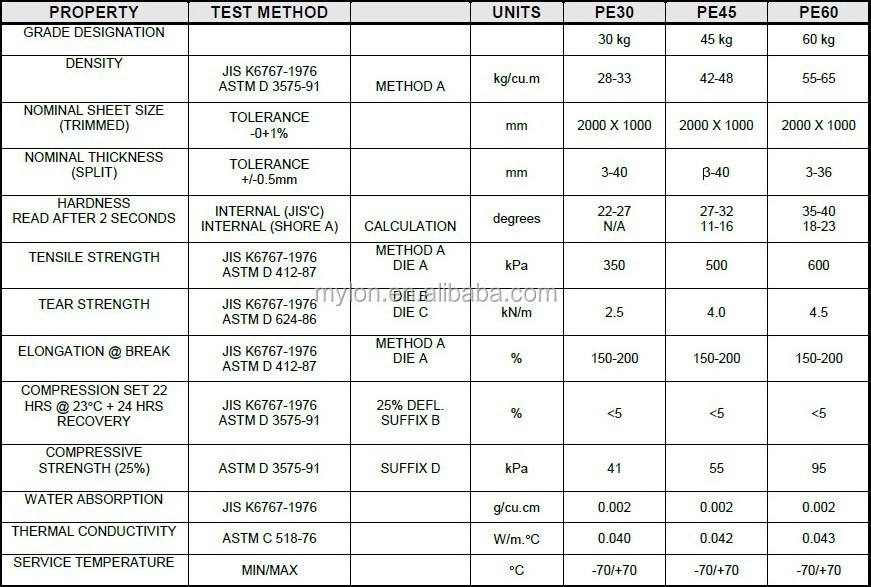

|

Item No. |

Material |

Density(kg/m3) |

Hardness(HC) |

Tensile(kpa) |

Elongation(%) |

Size(mm) |

|

PE40 |

PE |

25 |

16 |

160 |

180 |

2000*1000 |

|

PE30 |

PE |

32 |

20 |

180 |

220 |

2000*1000 |

|

PE25 |

PE |

50 |

25 |

400 |

190 |

2000*1000 |

|

PE20 |

PE |

60 |

30 |

450 |

240 |

1200*2300; 1200*3800; 1500*3800; 1500*4000 |

|

PE15 |

PE |

110 |

50 |

1000 |

150 |

1200*2300; 1200*3800; 1500*3800; 1500*4000 |

|

PE10 |

PE |

150 |

60 |

1100 |

160 |

1200*2300; 1200*3800; 1500*3800; 1500*4000 |

|

PE5 |

PE |

230 |

68 |

1500 |

150 |

1200*2300; 1200*3800; 1500*3800; 1500*4000 |

|

PE |

PE |

290 |

70 |

1300 |

90 |

1300*2600;900*1600 |

|

EVA30 |

EVA |

40 |

18 |

320 |

600 |

2000*1000 |

|

EVA25 |

EVA |

80 |

25 |

340 |

500 |

2000*1000 |

|

EVA20 |

EVA |

70 |

20 |

1000 |

250 |

1200*2300; 1200*3800; 1500*3800; 1500*4000 |

|

EVA15 |

EVA |

100 |

38 |

850 |

400 |

1200*2300; 1200*3800; 1500*3800; 1500*4000 |

|

EVA+RUBBER |

EVA |

100 |

26 |

900 |

200 |

1000*1950 1150*1800 |

|

SBR306 |

SBR |

190 |

7 |

250 |

300 |

1300*3300 |

|

SBR 320 |

SBR |

190 |

12 |

400 |

350 |

1300*3300 |

|

SBR 400 |

SBR |

190 |

7 |

450 |

450 |

1300*3300 |

|

CR140 |

CR |

150 |

7 |

600 |

650 |

1300*3300 |

|

CR150 |

CR |

160 |

12 |

650 |

700 |

1300*3300 |

|

CR325 |

CR |

240 |

25 |

750 |

320 |

1300*3300 |

|

CR330 |

CR |

300 |

28 |

850 |

320 |

1300*3300 |

|

N 200 |

PVC/NBR |

65 |

7 |

400 |

200 |

1900*900 |

|

N 100 |

PVC/NBR |

160 |

25 |

1000 |

125 |

2000*1000 |

|

N 100 |

PVC/NBR |

55 |

5 |

120 |

120 |

2000*1000*25 |

|

N200 |

PVC/NBR |

80 |

10 |

120 |

120 |

2000*1000*25 |

|

EPDM 496 |

EPDM |

250 |

10 |

650 |

180 |

2000*1000 |

|

EPDM 497 |

EPDM |

370 |

12 |

160 |

160 |

2000*1000 |

|

EPDM 100 |

EPDM |

90 |

7 |

300 |

300 |

2000*1000 |

|

TPE15 |

TPE |

120 |

30 |

230 |

260 |

1200/2050 |

|

spec:1m*2m |

|

|

|

|

|

|

|

|

examination project |

unit |

name |

|||||

|

L-1500 |

L-2000 |

L-2500 |

L-3000 |

L-4000 |

|||

|

tensile strength at break |

mpa |

|

|

|

0.25-0.3 |

|

|

|

elongation at break |

% |

240-290 |

220-250 |

180-230 |

170-200 |

150-180 |

|

|

ASKER“C”hardness |

° |

40-45° |

30-35° |

20-25° |

15-20° |

12-15° |

|

|

tear strength |

KN/M |

|

|

7-10 |

8.5-11 |

9-12 |

|

|

density |

Kg/m 3 |

60Kg/m 3 |

50Kg/m 3 |

40Kg/m 3 |

30Kg/m 3 |

25Kg/m 3 |

|

|

compression set |

% |

|

|

|

54.2 |

|

|

|

compression set |

Ø23mm specimen |

% |

0.2

|

0.2

|

0.2

|

0.2

|

0.2

|

|

24h*25% |

50*50mm specimen |

% |

|

|

|

|

|

|

combustion test(straight) |

B1 |

|

|

32 |

32 |

32 |

|

|

B2 |

|

|

26 |

26 |

26 |

||

|

ignitability |

|

|

|

≤150 |

|

||

|

Shore A |

Asker C |

Shore 00 |

g/cm³ |

PCF (lb/ft³) |

Application |

|

30-40 |

50-60 |

81-87 |

0.18-0.23 |

11.5-14.5 |

Mid-soles/wedges, Orthopedic shoes insole cushion/mid-sole |

|

45-55 |

65-75 |

89-92 |

0.21-0.26 |

13.0-16.0 |

Mid-soles/wedges, Orthopedic shoes insole cushion/mid-sole |

|

55-65 |

75-83 |

92-95 |

0.30-0.36 |

19.0-23.0 |

Mid-soles/wedges, Orthopedic shoes insole cushion/mid-sole |

|

22-30 |

40-50 |

73-81 |

0.15-0.21 |

9.5-13.0 |

Flat insoles/Molded insoles, Orthopedic shoes insole cushion/mid-sole |

|

30-40 |

50-60 |

81-87 |

0.20-0.25 |

13.0-16.0 |

Mid-soles/ Wedges, Orthopedic shoes insole cushion/mid-sole |

|

30-40 |

50-60 |

81-87 |

0.18-0.23 |

11.5-14.5 |

Mid-soles/Wedges, Orthopedic shoes insole cushion/mid-sole |

|

45-55 |

65-75 |

89-92 |

0.25-0.31 |

15.5-19.0 |

Mid-soles/Wedges, Orthopedic shoes insole cushion/midsole |

|

55-65 |

75-83 |

92-95 |

0.29-0.35 |

18.0-20.0 |

Mid-soles/Wedges |

|

20-28 |

38-48 |

70-80 |

0.14-0.19 |

8.5-12.0 |

Flat insoles/Molded insoles, Orthopedic shoes insole cushion/midsole |

|

30-40 |

50-60 |

77-83 |

0.18-0.25 |

11.5-15.5 |

Molded insoles, Orthopedic shoes insole cushion/midsole |

|

40-50 |

60-70 |

87-91 |

0.58-0.63 |

36.0-39.5 |

- |

|

50-60 |

70-79 |

91-94 |

0.58-0.63 |

36.0-39.5 |

- |

Mylon factory

NO MOQ large stock

Hot Searches