NaN / 0

PP hollow precast concrete mold wall panel formwork for sale

Get Latest Price

US$ 1.29

≥10000 Pieces

US$ 1.28

≥30000 Pieces

US$ 1.27

≥60000 Pieces

Quick Details

Warranty:

Lifetime

After-sale Service:

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection

Project Solution Capability:

graphic design, total solution for projects

Application:

Hotel

Product Details

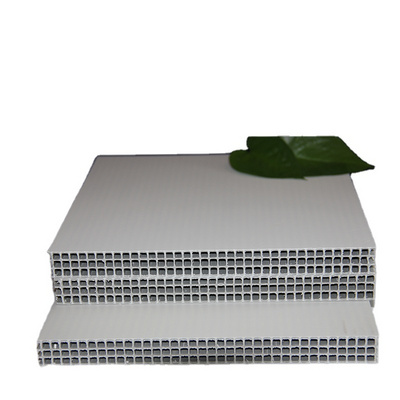

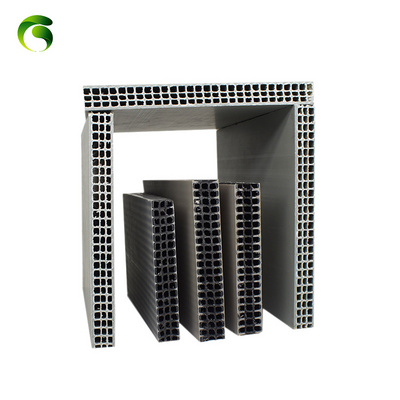

PP hollow precast concrete mold wall panel formwork

PP Hollow Formwork

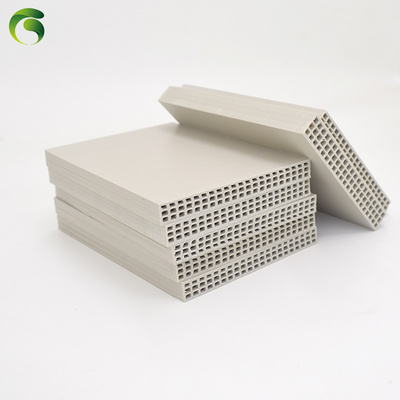

PP hollow precast concrete mold wall panel formwork is new kind of constrution concrete formwork. It is used high quality recycled polypropylene particles. It is suitable to realize concrete columns, pillars, walls, plinths, and foundations directly onsite. This formwork is according to the principle of structural mechanics, neatly arranged, increased four times support, stronger and more robust, on both sides of the formwork are right angle processing, increasing the bear capacity, construction is more convenient, its hollow structure makes the product expansion coefficient small and light easy to move. Now PP hollow structure formwork is becoming more and more popular.

Advantages:

1.Reuse average times more than 60, long service life.

2.High hardness. Can bear high press from the cement or concrete.

3.Good tenacity, within tolearence expansion, and shrinkage.

4.Light weight and easy to remove,operate and transport.

5.Waterproof, non-hygroscopic,size stable under the water.PP hollow precast concrete mold wall panel formwork.

6.The surface is smooth and clean, easy demould, no need mold release agent.

7.Good toughness. It could be used as cambered special-shaped formwork.

8.Waste products can be recycled and reprocessed, making full use of waste materials. This property can greatly reduce the project cost compared with wooden formwork and bamboo formwork.

9.Environmental protection and energy saving, no pollution. No any poisonous or harmful gas.

10. No absorption of moisture, no deformation, no mildew; Long-term immersion stratification in the water, no bubbles, sheet size stability.

Installation:

1.Use the hollow building formwork intersecting surface laid with 15mm thick.

2.Wood square of the distance:

(1) on the surface of the intersection (spacing: wood square distance according to the thickness of the slab concrete, in general, the thickness of less than 0.15 m floor (spacing is 200 ~ 250 mm.)

(2) the shear wall (spacing according to adjust the spacing, height and thickness of the wall to wall height of 2800 mm, 300 mm thick wall, for example, using the formwork (15 mm thickness spacing is 100 ~ 150 mm, if the shear wall, pillar width more than 1 meter, must add the fixed frame.

3.Die shear wall and column puzzle when leaving no gaps, internal Angle (the bottom of the wall) parts must have wood square, beam, wall, formwork connection.Shear wall made

4. After the mold must be assembled into the whole hoisting, then lay flat, reduce labor intensity, forming effect is good. Factory direct supply adjustable beams and columns formworks.

5. When the nail to the formwork from the formwork edge distance 15 ~ 30 mm, strength wants moderate, nail nails is 40 ~ 50 mm in length, shoulds not be too long or too short.

6.Beam bottom of a piece of wood square must set aside 15 mm seam allowance, wallboard made on wood square seam allowance, PP hollow plastic girders formwork for construction.

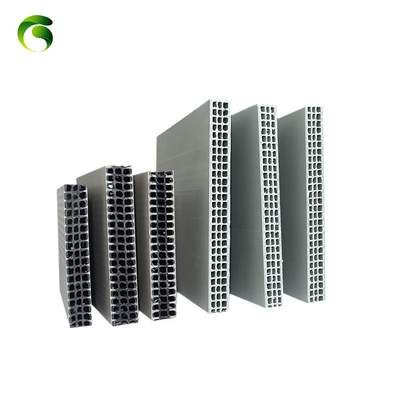

Specifications:

1. Basical Data:

| Size | Weight | Qty./20FT | Qty./40HQ |

| 1220*2440*12mm | 21-22KGS | 700 PCS | 1198 PCS |

| 1220*2440*15mm | 23-24KGS | 560 PCS | 1106 PCS |

| 1220*2440*18mm | 26-27KGS | 466 PCS | 981 PCS |

2. Technical Parameter:

| Test Item | PP hollow precast concrete mold wall panel formwork | ||||

| Requirements | Testing Result | Judge | Test Method | ||

| Shore Hardness (D) | ≥58 | 65.5 | Approved | GB/T 2411-2008 | |

| Dimensional change after heating, % | Landscape | ±0.2 | ±0.1 | Approved | jg/t418-2013 7.2.7 |

| Portrait | ±0.2 | ±0.1 | Approved | ||

| Simple bracket unnotched impact strength, kJ/m^2 | ≥30 | 33.7 | Approved | GB/T 1043.1-2008 | |

| Nail withdraw (N) | 741 | GB/T 17657-2003 4.21 | |||

Market Study:

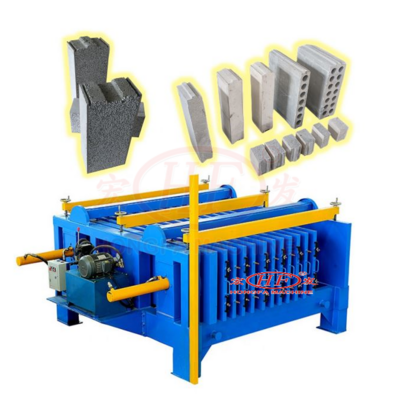

Plywood formwork is the most common and economic choice for constriction formwork. But with the times going on and the environmental requirements getting higher and more strictly, its short comings also getting more obviously. So plastic formwork became ist best substitute. Like PVC formwork and PP hollow formwork. Factory direct supply adjustable beams and columns formworks.

PP hollow construction building formwork with its light weight, waterproof and more reusable times advantages, make it more and more popular in formwork market.

The shortage of plwood formwork lead to import timber price rising and make it cost higher. Besides, the wooden formwork is not recycled which causes a large waste and operating cost of construction. Plastic formwork is a kind of energy-saving and environmental protection products. Replace of traditional pine plywood formwork already happend.

About Us-Green Plastic

Shandong Green Plastic is a manufacturer and trading company focus on plastic products exporting. High quality goods and professtional exporting experience are our advantages. This earns us high reputation from overseas and China domestic customers. Now except China domestic market, we also export USA, AU, Canada, UK, Vietnam, Mexico ect. more than 45 countries. Now our goods is widely use the most corners around the world. We located a nice palce where its convenient comunications and facilities. Zhangqiu, Jinan City, Shandong Provice. A vibrant city and company welcome your visiting and inquiries. Factory direct supply adjustable beams and columns formwork.