NaN / 0

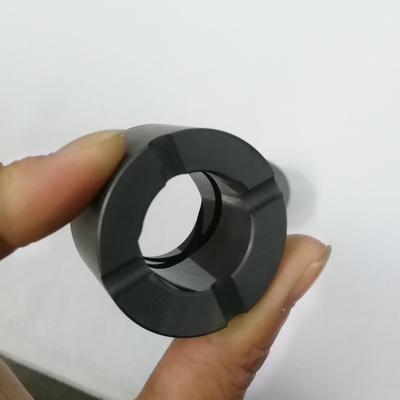

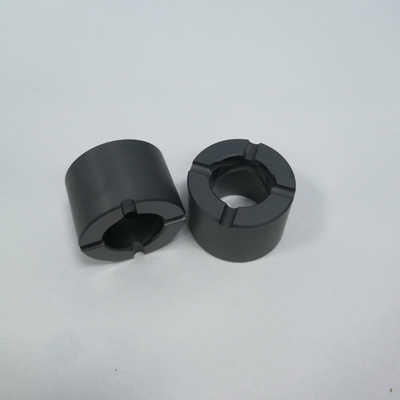

Factory direct RBSIC& SSIC Silicon Carbide Bushing/sleeve for Pumps

Get Latest Price

US$ 30

≥30 Pieces

US$ 29

≥100 Pieces

US$ 28

≥500 Pieces

Quick Details

Place of Origin:

Henan, China

Model Number:

ZJLSCP-02

Brand Name:

Aryan

Material:

silicon carbide

Product Details

High compressive strength above 2200MPa silicon carbide/sic sleeve

1.Introduction of Silicon Carbide:

Silicon carbide (SiC), also known as carborundum, is a compound of silicon and carbon with a chemical formula SiC. It occurs in nature as the extremely rare mineral moissanite. Silicon carbide powder has been mass-produced since 1893 for use as an abrasive. Grains of silicon carbide can be bonded together by sintering to form very hard ceramics which are widely used in applications requiring high endurance, such as car brakes and ceramic plates in bulletproof vests. Electronic applications of silicon carbide as light emitting diode and detector in early radios have been demonstrated around 1907, and nowadays SiC is widely used in high-temperature semiconductor electronics. Large single crystals of silicon carbide can be grown by the Lely method; they can be cut into gems known as "synthetic moissanite". Silicon carbide with high surface area can be produced from SiO2 contained in plant material.

2 .Features of Sic Ceramic Sleeve :

1) Heat shock stablity

2) chemical corrosion-resistant

3) High temper-endure(up to 1650°

4) Wearing/corrosion/oxidation resistant

5) Highly performance of mechanical strength

6) Cleaning or etching the hardest sub-surfaces

7) Used for grinding, lapping, and wire saw cutting as well as abrasive blasting

3.Properties:

4.Application:

5. production lines:

Granulation-compression moulding-sintering-grinding -finishing and fining

the inspection for each step of the production is conducted strictly.

Why choose us

|

Our advantages

|

High quality |

|

Competitive price |

|

| Strict delivery time | |

| Good after-sales service | |

|

Professional manufacturer for 10 years |

|

|

Gold supplier 3 th year |

|

|

Strict quality control |

If you have any questions, please don't hesitate to contact us. Our factory&office is located in Zhengzhou, Henan province. Welcome to visit us.

Our goal is to put the often extreme properties of technical ceramics to the best use.

Hot Searches