NaN / 0

100% Original Factory Sale Beneficiation Equipment Chrome Ore Processing Plant Titanium Spiral Chute Gravity Separator For Gold

Get Latest Price

US$ 1680

≥1 Sets

US$ 1600

≥2 Sets

US$ 1550

≥5 Sets

US$ 1500

≥10 Sets

Quick Details

Production Capacity:

90%

Place of Origin:

Jiangxi, China

Brand Name:

Henghong

Dimension(L*W*H):

1060*1060*4000mm

Product Details

Main Features

1. High recovery, high efficiency, and precise separation

2. Non-required power,low operation cost

3. Light in weight, anti corrosion, rust and wear resistant

4. Simple installation and Minimal maintenance requirements

5. Strong adaptability to fluctuation of feeding amount, density, size and grade

100% Original Factory Sale Beneficiation Equipment Chrome Ore Processing Plant Titanium Spiral Chute Gravity Separator For Gold

Jiangxi Henghong mining machinery is devoting to provide turnkey solution with worldwide clients for mineral processing plant including research, design, manufacture,installation and commissioning, personnel training, after-sale service and management of processing plant. Up to now, we have developed five major product lines: they are mining crushing machine, mining milling machine,mining classifying separator, mining flotation machine and the mining gravity separator. When you find us, you find one best mining machinery manufacturer.

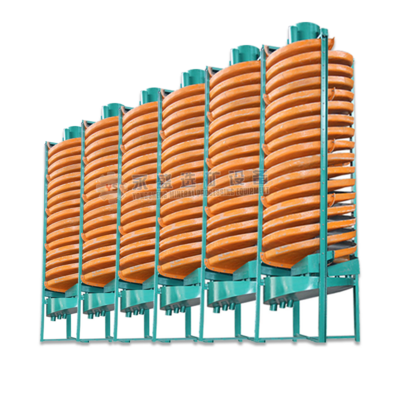

Spiral Chute Separator Introduction

Spiral chute is also called spiral chute or spiral chute separator, is the best equipment in mining and ore dressing industries,which is often applied to sort materials with size 0.3 - 0.02 mm, such as ilmenite, chromite, pyrite, zircon, rutile, monazite, phosphate, tungsten ore, tin, tantalum, niobium ore and other non-ferrous metals, precious metals and non-metallic minerals.

It can easily adopt to different raw material size, density, ore grade and feed volume. Spiral chute is suitable for treatment of 0.6-0.03mm lode and placer, but high mud content is bad for separation. At present, spiral chute has been widely used in the treatment of iron ore, tungsten, tin ore, niobium tantalum ore, coastal and riverside placer and gold ore.The spiral chute is a gravity equipment. With the water, action of gravity friction force, minerals would be separated by its gravity difference. Then we could get heavy, middling and light products.It is made of the fiberglass lined with wear-resistant polyurethane and corundum cover; the advantages are light, moisture proof, anti-rust, wear proof,anti corrosion and no noise, properly suitable for the different feeding particle sizes and grades. It is the domestic advanced level, the new high effective equipment.

It can easily adopt to different raw material size, density, ore grade and feed volume. Spiral chute is suitable for treatment of 0.6-0.03mm lode and placer, but high mud content is bad for separation. At present, spiral chute has been widely used in the treatment of iron ore, tungsten, tin ore, niobium tantalum ore, coastal and riverside placer and gold ore.The spiral chute is a gravity equipment. With the water, action of gravity friction force, minerals would be separated by its gravity difference. Then we could get heavy, middling and light products.It is made of the fiberglass lined with wear-resistant polyurethane and corundum cover; the advantages are light, moisture proof, anti-rust, wear proof,anti corrosion and no noise, properly suitable for the different feeding particle sizes and grades. It is the domestic advanced level, the new high effective equipment.

Working Principle

Spiral chute is working under the the force of water flow, gravity, inertial centrifuge and friction. Slurry is pumped to the top of the spiral , and it enters a feed distributor that evenly distributes the feed to each spiral concentrator. The design and shape of the spiral make it work, when combined with gravitational acceleration. As the slurry travels the spiraling path down the spiral, mineral grains settle and start sorting according to size, density and to a lesser extend shape. Low density particles are carried with the bulk of the water towards the outside of the spiral , while particles with the greatest density migrate towards the inside of the spiral.

|

Model

|

BLL-1500

|

BLL-1200

|

BLL-900

|

BLL-600

|

|

Outside Diameter (mm)

|

1500

|

1200

|

900

|

600

|

|

Screw Pitch (mm)

|

900, 675

|

900, 720, 540

|

675, 540, 405

|

450, 360, 270

|

|

Pitch Diameter Ratio

|

0.48, 0.36

|

0.75, 0.6, 0.45

|

0.75, 0.6, 0.45

|

0.75, 0.6, 0.45

|

|

Lateral slope (degree)

|

9°

|

9°

|

9°

|

9°

|

|

Max. Screw Numbers

|

4

|

4

|

4

|

2

|

|

Feed Size (mm)

|

0.8 ~0.037

|

0.3~0.03

|

0.3 ~0.03

|

0.2~0.02

|

|

Feed Density (%)

|

30 ~55

|

25 ~55

|

25 ~55

|

25 ~55

|

|

Capacity (t/h)

|

6~8

|

4~6

|

2~3

|

0.8~1.2

|

|

Length (mm)

|

1600

|

1360

|

1060

|

700

|

|

Width (mm)

|

1600

|

1360

|

1060

|

700

|

|

Height (mm)

|

5300

|

5230

|

4000

|

2600

|

|

Weight (kg)

|

850/800

|

700/650/600

|

450/400/350

|

150/120/100

|

More Products

Q:1.What is your machine used for ?

A: Our Spiral Chute is used for separation the materials such as Gold, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten ore, tin, tantalum, niobium ore etc.

Q: 2.Are you factory or trade company?

A: Yes dear,we are the Professional manufacturer from 1985.So we could give you original factory price than those trade companies.

We're also warmly welcome your Visiting our factory if you are coming to China.Please Call at +86-18870736160

Q: 3.Can I operate it well, if I have no experience?

A: Do not worry! Our machines is designed to use easily.You are welcome to visit our company to be trained here,And we could arrange the engineer to go to your country/company to train your workers directly as your requested and the relative travel cost will be on your account.

Q:4.Can you send me the video to show how the machine works?

A: Surely.we have made video of every machine,so if you need we can send for you to checking in clearly.

Q:5. What should I take care when using the machine?

A: Please using the machine in regular and Keeping the machine away from thinner and other chemical liquid.

Q:6.How about the service of your company?

A:24Hours Online service.all machines have one year warranty and Wholelife Technology support to make sure your machine work well.

Q:7.How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q:8 What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

A: Our Spiral Chute is used for separation the materials such as Gold, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten ore, tin, tantalum, niobium ore etc.

Q: 2.Are you factory or trade company?

A: Yes dear,we are the Professional manufacturer from 1985.So we could give you original factory price than those trade companies.

We're also warmly welcome your Visiting our factory if you are coming to China.Please Call at +86-18870736160

Q: 3.Can I operate it well, if I have no experience?

A: Do not worry! Our machines is designed to use easily.You are welcome to visit our company to be trained here,And we could arrange the engineer to go to your country/company to train your workers directly as your requested and the relative travel cost will be on your account.

Q:4.Can you send me the video to show how the machine works?

A: Surely.we have made video of every machine,so if you need we can send for you to checking in clearly.

Q:5. What should I take care when using the machine?

A: Please using the machine in regular and Keeping the machine away from thinner and other chemical liquid.

Q:6.How about the service of your company?

A:24Hours Online service.all machines have one year warranty and Wholelife Technology support to make sure your machine work well.

Q:7.How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q:8 What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Q:9 What's Information we need from your side ?

A: What's kind of ore do you want to processing? maximum feeding size and capacity per hour please ?

A: What's kind of ore do you want to processing? maximum feeding size and capacity per hour please ?

Warmly Welcome to Sending Inquiry,We will give 100% positive responses.

Hot Searches