NaN / 0

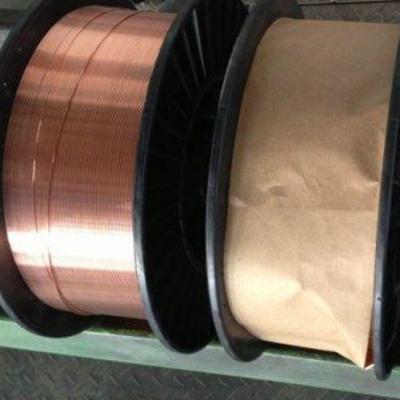

Carbon Steel Gas Shiled Solid Core Welding Wire ER70S-2

Get Latest Price

US$ 950

≥5 Tons

US$ 925

≥15 Tons

Quick Details

Material:

carbon steel

Diameter:

0.6mm-2.0mm

Melting Point:

International Standard

Weight:

5kg ,15kg,25kg

Product Details

Carbon Steel Gas Protect Solid Core Welding Wire ER70S-2

Description

Product Details

|

Model |

Secifications |

C |

Mn |

Si |

S |

P |

Cr |

Ni |

Cu |

Mo |

Ti |

V |

|

ER70S-2 |

0.6mm 0.8mm 0.9mm 1.0mm 1.2mm 1.4mm 1.6mm 2.0mm |

≤0.07 |

0.9-1.4 |

0.4-0.7 |

≤0.025 |

≤0.025 |

- |

- |

≤0.5 |

- |

- |

- |

|

ER70S-3 |

0.06-0.15 |

0.9-1.4 |

0.45-0.75 |

≤0.025 |

≤0.025 |

≤0.15 |

≤0.15 |

≤0.5 |

≤0.15 |

- |

≤0.03 |

|

|

ER70S-6 |

0.06-0.15 |

1.4-1.85 |

0.8-1.15 |

≤0.025 |

≤0.025 |

≤0.15 |

≤0.15 |

≤0.5 |

≤0.15 |

- |

≤0.03 |

|

|

ER70S-G |

≤0.15 |

1.4-1.9 |

0.55-1.1 |

≤0.03 |

≤0.03 |

Ti+Cr≤0.3 |

- |

≤0.5 |

- |

- |

- |

Mechanical properties of deposited metal

|

Model |

Yield point Rm(Mpa) |

Tensile strength Rel/Rp0.2(Mpa) |

Elongation A(%) |

KV2(J) Temp( ℃ ) |

KV2(J) AKV(J) |

|

ER70S-2 |

≥500 |

≥420 |

≥22 |

-30 |

≥27 |

|

ER70S-3 |

≥500 |

≥420 |

≥22 |

-20 |

≥27 |

|

ER70S-6 |

≥500 |

≥420 |

≥22 |

-30 |

≥27 |

|

ER70S-G |

≥500 |

≥420 |

≥22 |

-30 |

144 131 127 |

Advantages

1.The welding wire is steady to transfer wire.

2.The welding line is formed beautiful.

3.The welding fog and splash is little.

4. It has good fluidity and anti-crack resistance.

5. The welding slag is thin and easy to fall.

6. The welding line has good breaking strenhthand anti-low temperature impact resistant performance.

7. It is applied for welding of all- position and bigger eletric current range.

Packing & Delivery

Packing: 5kgs/spool

15kgs/spool

20kgs/spool

Delivery:15 days after order confirmed

Company

Our compamy is a specialized manufacturer of welding products registered in 1996, the annual production capacity exceeding 5000tons. The main products of our company are welding electrodes, welding wires and welding accessories. With more than 20 years’ working experience, we have strict quality testing and perfect service system.

Our certificates