NaN / 0

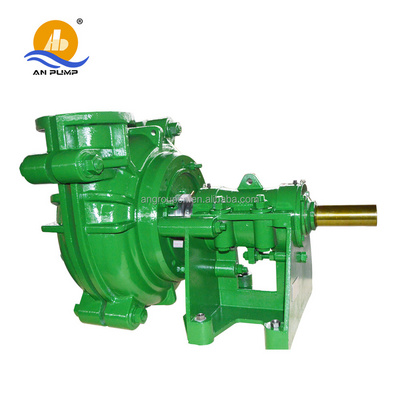

Mine Mineral Dirty Water Heavy Duty Recycle Water Slurry Pump

Get Latest Price

US$ 256

≥1 Sets

Quick Details

Application:

Industrial Utilities, Machining, Marine, Metal and Equipment Manufacturers, Mining industry, demineralized pump, horizontal gold mining slurry pump, mud sucking centrifugal end suction slurry pump, gold water pump machine

Pressure:

High pressure ash slurry pump

Voltage:

220 - 6 kv

Warranty:

3 years slurry pump for bottom ash

Product Details

Mine Mineral Dirty Water Heavy Duty Recycle Water Slurry Pump

What is the Slurry Pump?

The slurry pump is widely used at the mining and mineral process to transfer the ore mixed with water.

No matter g ravity separation,magnetic separation or flotation to get the mine, you should need the slurry pump to make all system workable and the slurry pump also used to transfer the slurry out off the mineral process to tailing dam.

An Pump Machinery Co., Ltd is one professional and your one stop at the mining and mineral pump system or your mining dewatering system, Clikc An Pump Machinery Profile for more...

AM(R) horizontal slurry pump is the heavy duty pump special designed for mining and mineral process slurry transfer.

Pump Description

AM(R) Mining and Mineral Grease Lubricationhorizontal slurry pump is the horizontal, cantilevered centrifugal slurry pump , with reasonable construction, reliable operation, long service life. It is widely used in transporting abrasive or / and corrosive slurry in mining, metallurgy, electric power, coal, chemicals, building, etc. Especially well accepted by coal / chrome washing plant, mineral processing plant, power plant etc .

Design Features of Mine Mineral Dirty Water Heavy Duty Recycle Water Slurry Pump

• Bearing assembly – A large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame.

• Liners – Easily replaceable liners are bolted, not glued, to the casing for positive attachment and ease of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomers. Elastomer seal rings back all liner joints.

• Casing – Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety.

• Impeller – Front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are completely interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available.

• Throat bush – Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

• One-piece frame – A very robust one-piece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for

easy adjustment of impeller clearance.

Pump Structure

Mine Mineral Dirty Water Heavy Duty Recycle Water Slurry Pump Structure

|

Metal liner |

Rubber liner |

||

|

1 |

Volute liner |

1 |

Frame plate |

|

2 |

Frame plate |

2 |

Expeller ring |

|

3 |

Frame plate liner insert |

3 |

Gland assembly |

|

4 |

Cover plate |

4 |

Shaft sleeve |

|

5 |

Throat bush |

5 |

Expeller |

|

6 |

Impeller |

6 |

Frame plate liner |

|

7 |

Expeller ring |

7 |

Impeller |

|

8 |

Shaft sleeve |

8 |

Cover plate liner |

|

9 |

Expeller |

9 |

Cover plate |

|

10 |

Bearing assembly |

Note: Slurry pumps have Throat Bush from 4" |

|

Mine Mineral Dirty Water Heavy Duty Recycle Water Slurry Pump Performance Data

|

Model |

Clear water performance |

||

|

Capacity Q (m3/h) |

Head H ( m) |

Speed n (rpm) |

|

|

1.5/1B-AM |

12.6~28.8 |

6~68 |

1200~3800 |

|

10.8~25.2 |

7~52 |

1400~3400 |

|

|

1.5/1B-AMH |

16.2~34.2 |

25~92 |

1400~2200 |

|

2/1.5B-AM |

32.4~72 |

6~58 |

1200~3200 |

|

25.2~54 |

5.5~41 |

1000~2600 |

|

|

3/2C-AM |

39.6~86.4 |

12~64 |

1300~2700 |

|

36~75.6 |

13~39 |

1300~2100 |

|

|

4/3C-AM |

86.4~198 |

9~52 |

1000~2200 |

|

4/3D-AM |

|||

|

4/3C-AM |

79.2~180 |

5~34.5 |

800~1800 |

|

4/3D-AM |

|||

|

4/3E-AMH |

126~252 |

12~97 |

600~1400 |

|

6/4D-AM |

162~360 |

12~56 |

800~1550 |

|

6/4E-AM |

|||

|

6/4D-AM |

144~324 |

12~45 |

800~1350 |

|

6/4E-AM |

|||

|

6/4F-AMH |

100~414 |

34~98 |

600~1000 |

|

8/6E-AM |

360~828 |

10~61 |

500~1140 |

|

8/6E-AM |

324~720 |

7~49 |

400~1000 |

|

10/8ST-AM |

612~1368 |

11~61 |

400~850 |

|

540~1188 |

12~50 |

400~750 |

|

|

10/8E-MM |

666~1440 |

14~60 |

600~1100 |

|

10/8E-MM |

540~1188 |

10~42 |

500~900 |

|

12/10ST-AM |

936~1980 |

7~68 |

300~800 |

|

720~1620 |

7~45 |

300~650 |

|

|

14/12ST-AM |

1260~2772 |

13~63 |

300~600 |

|

1152~2520 |

13~44 |

300~500 |

|

|

16/14ST-AM |

1368~3060 |

11~63 |

250~550 |

|

16/14TU-AM |

|||

|

18/16ST-AM |

2160~5040 |

8~66 |

200~500 |

|

18/16TU-AM |

|||

|

20/18TU-AM |

2520~5400 |

13~57 |

200~400 |

Mine Mineral Dirty Water Heavy Duty Recycle Water Slurry Pump Performance Curve

Pump Application

What's the applications of Mine Mineral Dirty Water Heavy Duty Recycle Water Slurry Pump?

Packaging & Shipping

Mine Mineral Dirty Water Heavy Duty Recycle Water Slurry Pump package and Shipping Term

Hot Searches