2.We will send the instruction book to you to let you install the machine. You can talk with our engineer by video chat or we will send the engineers overseas to help you.

|

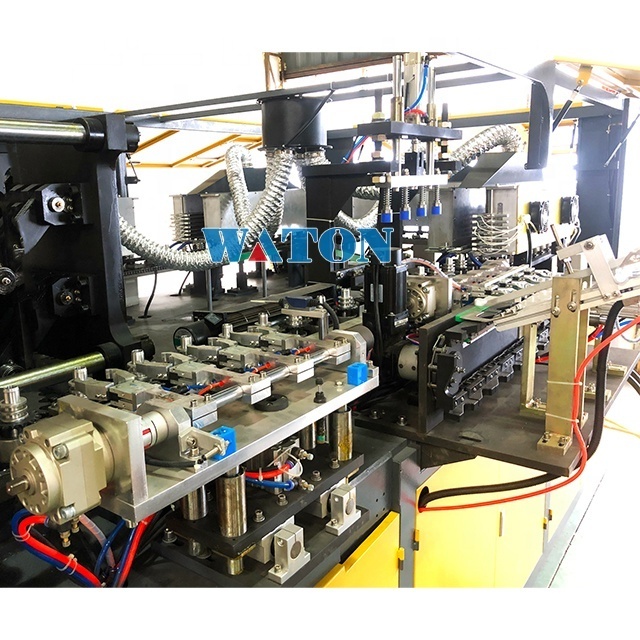

Models

|

ECO-4L

|

|

Theoretical Capacity

|

3600-4500 BPH

|

|

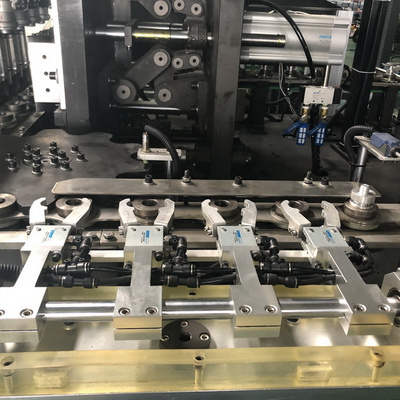

Mold Cavities

|

4

|

|

Neck Size

|

18-38 mm

|

|

Max. Volume

|

2000 ml

|

|

Advantages

|

High productivity; easy to operate; long time after-sale service.

|

Description of application effect

|

Models

|

|

ECO-2

|

ECO-4S

|

ECO-4L

|

ECO-6S

|

ECO-6L

|

|

|

Theoretical Capacity(BPH)

|

|

1,800~2,400

|

4,600~5,000

|

3,600~5,000

|

6,000~7,000

|

5,000~6,000

|

|

|

Mold Cavities

|

|

2

|

4

|

4

|

6

|

6

|

|

|

Bottle

|

Neck Size

|

18-38mm

|

18-38mm

|

18-38mm

|

18-38mm

|

18-38mm

|

|

|

|

Max. Volume

|

2000ml

|

750ml

|

2000ml

|

750ml

|

2000ml

|

|

|

|

Max. Diameter

|

105mm

|

69mm

|

105mm

|

69mm

|

105mm

|

|

|

|

Max. Height

|

330mm

|

240mm

|

330mm

|

240mm

|

330mm

|

|

|

Power

|

Heater qty

|

16pcs

|

21pcs

|

32pcs

|

28pcs

|

48pcs

|

|

|

|

Heating Area

|

2

|

3

|

4

|

4

|

6

|

|

|

|

Heating Power

|

35KW

|

46KW

|

70KW

|

62KW

|

106KW

|

|

|

|

Rated General Power

|

37KW

|

50KW

|

75KW

|

65KW

|

110KW

|

|

|

High Pressure Air Consumption(m3/min)

|

|

2.0

|

3.0

|

4.0

|

5.0

|

6.0

|

|

|

Main Machine Size

|

|

3000*1800*2400mm

|

3300*2000*2200mm

|

4200*2100*2400mm

|

4200*2050*2200mm

|

5800*2150*2400mm

|

|

|

Main Machine Weight

|

|

2500KGS

|

3600KGS

|

5000KGS

|

5500KGS

|

7800KGS

|

|