NaN / 0

High Quality Stainless Casting Product Precision Metal Lost Wax Casting

Get Latest Price

US$ 1

≥100 Pieces

Quick Details

Place of Origin:

Shandong, China

Brand Name:

WABON

Model Number:

Non-standards

Process:

Investment casting

Product Details

1.1

1.2

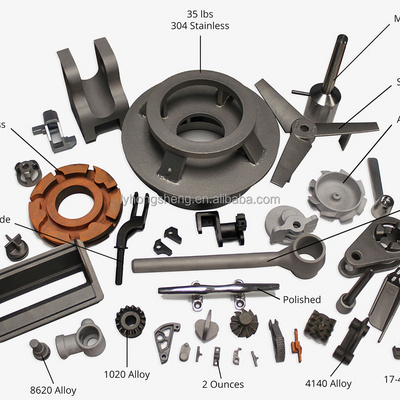

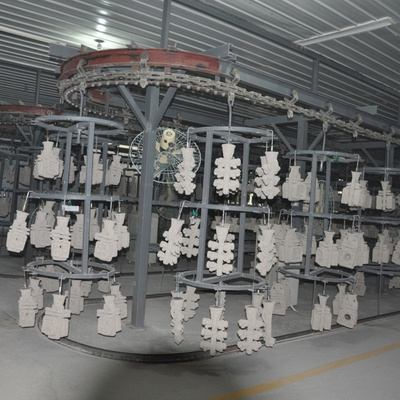

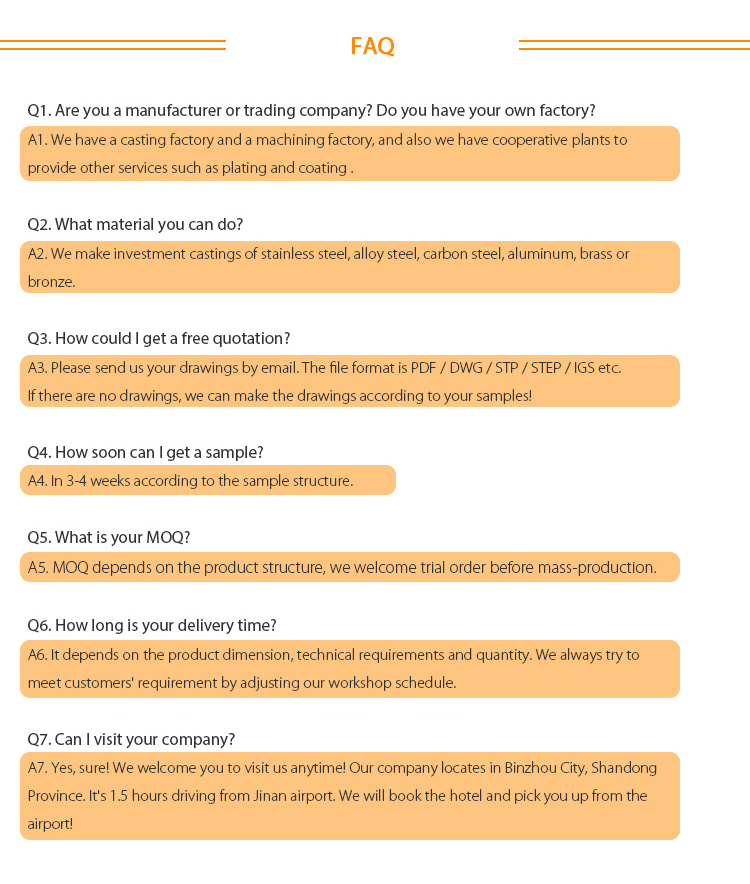

Our factory supply OEM service(custom service) in precision investment casting ,which are also called lost wax casting , We have been committed to this technique for over 10 years . Our specialized engineer can provide you the full-service of technology advice and products improving projection,and also reduce the cost of the parts.

|

Investment casting (lost wax casting)

|

Stainless steel casting Alloy steel casting Carbon steel casting Bronze and Brass casting Aluminum casting |

|

Machining |

Drilling, Reaming and tapping CNC Turning machining CNC Milling machining Wire EDM |

|

Heat treatment |

Annealing Solution Normalizing Tempering Quenching Induction hardening Hardening and tempering |

|

Surface treatment |

Manual polishing Electro-polishing Electro-plating Power coating Tumbling |

1.4

|

Process |

Investment casting Shell mold casting Lost wax casting |

|

Processing Ability |

Surface finishment: Ra1.6-Ra3.2 |

|

Size tolerance: VDG P690 D2 |

|

|

Maximum size: ≤1200mm×800mm×400mm |

|

|

Weight range: 0.1Kg-120Kg |

|

|

Material |

stainless steel, carbon steel, alloy steel, heat-resistant steel, hardend steel,mild steel |

|

Brass CuZn38,H62 Aluminum bronze AB2,863 |

|

|

Cast aluminium alloy ZL101,ZL114A,A356 |

|

|

Application |

Mechanical Components/parts Boat parts and Marine hardware Construction hardware Auto parts and accessories Medical Instrument parts pump & valve parts and accessories Impellers and propellers(propellors) Pipe Fittings or pipeline accessories Other industry metal casting parts |

|

Design |

Various type of 2D or 3D drawings are acceptable,such as JPG,PDF,DWG,DXF,IGS,STP,X_T,SLDPRT etc. |

|

Standards |

AISI,ATSM,UNI,BS,DIN,JIS,GB etc. |

|

Inspection |

Dimension inspection Chemical composition analysis (Spectrum analysis) Mechanical property testing X-Ray inspection Dye penetrant inspection Magnetic powder inspection Metallographic inspections |

1.7

1.3

1.5

1.6