NaN / 0

Magpow PVA white glue for wood working Flooring adhesive Wood Glue

Get Latest Price

US$ 0.15

≥1000 Pieces

Quick Details

CAS No.:

9009-54-5

Other Names:

White Glue

MF:

C3H4O2

EINECS No.:

232-554-6

Product Details

Magpow PVA white glue for wood working Flooring adhesive Wood Glue

We can provide the raw glue if you need!!!

Product Description

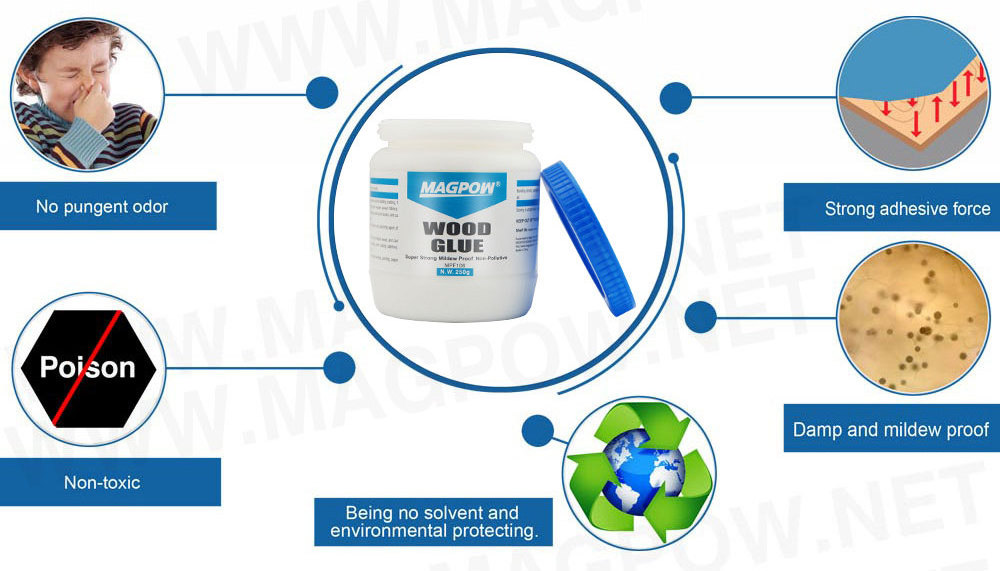

Product Feature

| Commodity | Item | Appearance | PH | Viscosity(25℃), mPa.s | Shear Strength, MPa | Solid content(%) |

| 20% Solid content | SK-221 |

Milk white Mucus,

no obvious granule |

4-6 | 15000-25000 | ≥4 | 20±2 |

| 25% Solid content | SK-2072 | 4-6 | 15000-25000 | ≥4 | 25±2 | |

| 30% Solid content | SK-2073 | 4-6 | 15000-25000 | ≥4 | 30±2 | |

| 40% Solid content | SK-2074 | 4-5 | 15000-25000 | ≥4 | 40±2 | |

| 50% Solid content | SK-2075 | 4-5 | 15000-25000 | ≥4 | 50±2 |

Specification

Scope of Application

50% solid content mainly for water-solubility construction coating raw material, to the lumber, the paper, the leather, the linter fabric, the cement and the foam plastics and so on has the good binding property, may serve as the books wireless to bind, cigarette, boding and sizing of fabrics.

40% solid content is mainly for wood processing, cigarette and bonding and sizing of fabric.

30% solid content mainly use as sticks for paper, small lumber, available in paper processing (paper pulp chemical additive, paper soaking, spreads cloth to help medicinal preparation), fabric processing, cement intensifier, handicraft production and culture and education office supplies bond.

25% solid content mainly uses in the officing, printing, the paper box processing, the low-grade paper tube processing, the handicraft and the paper caking and so on.

Directions

1. The joint surface must be clean, dry.

2. Spreads the glue on the joint surface, presses till solidification, maintains for 24 hours under the room temperature to achieve the use intensity.

Exhibition

Production Line

Notice

1.The iron barrel packing is strictly prohibited

2.The using temperature should be 10 ℃ or above; After agglutination product before solidification, also should maintain in 10 ℃ above. Otherwise will cause viscosity drop if the emulsion not form good cover.

3.Wipe the bottle mouth clean after use, cover rapidly for usage next time.

4.IF the glue with half coagulation condition please mix evenly, does not affect the viscosity.

5.The water content of wood should be controlled between 8~15%,more or less content will affect the viscosity quality.

6.Do not get into mouth, keep our reach of kids.

Storage and Packing

1.The product should be stored at temperature 5~37℃ in sealed non-metal container, prevent from freeze and high temperature. The shelf life is one year from date of production. It is available to use based on passing of the test if being beyond the shelf life.

2.If the glue slightly freezes, should place in 30~40 ℃ greenhouses the full alleviation, and stirs evenly, does not affect the use. If the glue long time receives seriously freezes, cannot alleviate, appears agglomerates, the lamination even emulsion breaking, then cannot continue to use.

3.Preserve and transport as flammable products.

Our Company View

HUNAN MAGPOW ADHESIVE GROUP CO., LTD

Was founded in 1989, Leaders at all levels of care and guidance, in the community friends and the majority of customers with the help and support, has gone through more than 20 years of arduous pioneering and steady development process. Companies from the original workshop-style processing plant to national "Torch Plan" implementation of enterprises, national standards of enterprises, the state's key high-tech enterprises. Group assets worth 150 million.

Our Team

As the country's largest private enterprise adhesive technology research institute. The Research Institute covers an area of 3600 square meters. A total of five layers, Divided into 28 advanced equipment, full-featured professional laboratory. The company invested more than 1100 million one-time, And The introduction of more than 20 sets of world-class test and testing equipment from Germany and Taiwan. The Research Institute has made a number of international advanced level of scientific research and national invention patents. At present, the company is actively reporting to create a national technology research institute-Global Adhesive Laboratory.

Certificates

Market Distribution

After-Sales Service

Reply within 24 Hours

Professional consultation service is available within 24 hours after receiving your feedback regarding the iterms that you bought. Global Insurance Service

Global insurance service

guarantees the safety of iterms when installation and application.

Compensation Policy

Any quality problem caused by our company side with enough evidence, we promise you that if could bere-produced for free.

Contact us, you will get more than what you see!

Hot Searches