NaN / 0

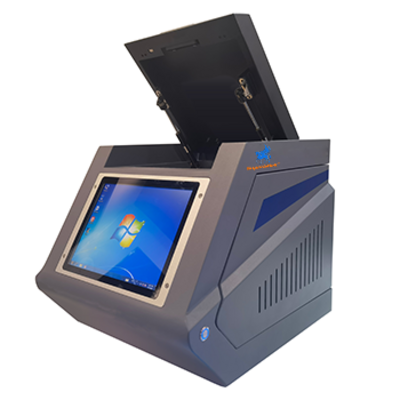

Diamond Trade X Ray Detector Korea Purity Of Palladium Gemstone Tester 1 Thermo Amptech Gold Testing Machine Pistola Metales Oro

Get Latest Price

US$ 19500

≥1 Sets

Quick Details

Warranty:

1 Year

Power:

Electronic

Place of Origin:

Guangdong, China

Brand Name:

LANScientific

Product Details

4Handheld Mineral Analyzer (TrueX 960)

Application Fied:

Raw ore rough detection, laboratory sample sorting, etc.

Ø Technology performance

1. Realize site fast, non-damage and exact analysis really, and show element content by ppm or percentage directly.

2. Small volume, fast and high precision.

3. The analysis samples can be solid and liquid objects like ores, rocks, slags, fragments, soil, slurry etc.

4. It can do intelligent test for uneven or small samples, also very small samples can be measured and recognized.

5. You just need to make it touch the object surface, then you can determine ore grade, element types and content in site.

6. It can keep high performance working even under direct big sunshine and high temperature, which benefits from the low power

consumption and timely discharge of great heat in the design.

7. Endure server working condition: sealed with wear and scratch resistant full metal shell, then it can work normally in the rainy and dusty mineral environment.

8. Considering workers’ long usage of equipment, then the design insures the safety as most important thing, the key parts are sealed in full metal to achieve the global lowest radiation standard.

9. Electromagnetic jams are shield, so it can work even close to mobile phone or dural wireless communication devices.

2. Small volume, fast and high precision.

3. The analysis samples can be solid and liquid objects like ores, rocks, slags, fragments, soil, slurry etc.

4. It can do intelligent test for uneven or small samples, also very small samples can be measured and recognized.

5. You just need to make it touch the object surface, then you can determine ore grade, element types and content in site.

6. It can keep high performance working even under direct big sunshine and high temperature, which benefits from the low power

consumption and timely discharge of great heat in the design.

7. Endure server working condition: sealed with wear and scratch resistant full metal shell, then it can work normally in the rainy and dusty mineral environment.

8. Considering workers’ long usage of equipment, then the design insures the safety as most important thing, the key parts are sealed in full metal to achieve the global lowest radiation standard.

9. Electromagnetic jams are shield, so it can work even close to mobile phone or dural wireless communication devices.

10. The fastest analysis speed in the world, only 2s can identify mineral element.

Ø Elements to be Analyzed and Test Modes

Ø Analysis of ore types

1. Iron ore (hematite, titanium, iron, etc.)

2. Copper (chalcopyrite, cuprite, malachite etc.)

3. Chromium (chromium spinel, chromite, chrombismite etc.)

4. Molybdenum (copper molybdenum, molybdenum, tungsten and molybdenum ore etc.)

5. Tungsten (tin tungsten scheelite, wolframite, etc.)

6. Tantalum ore (tantalite columbite, pyrochlore, etc.)

7. Lead-zinc ore (galena, sphalerite, cerussite etc.)

8. nickel laterite ore, copper nickel sulphide etc.

9. Gold in ore or alluvial gold detection

10. Other minerals detection

2. Copper (chalcopyrite, cuprite, malachite etc.)

3. Chromium (chromium spinel, chromite, chrombismite etc.)

4. Molybdenum (copper molybdenum, molybdenum, tungsten and molybdenum ore etc.)

5. Tungsten (tin tungsten scheelite, wolframite, etc.)

6. Tantalum ore (tantalite columbite, pyrochlore, etc.)

7. Lead-zinc ore (galena, sphalerite, cerussite etc.)

8. nickel laterite ore, copper nickel sulphide etc.

9. Gold in ore or alluvial gold detection

10. Other minerals detection

Ø Usage

1. Exact grade evaluation for high grade and beneficiated ores, then provide value foundation for ore trade, processing and recycling.

2. The relict ore element analysis in slag and tails to rejudge the value.

3.Conduct QC in ore mining, boring, grinding, concentration and smelting, then confirm grade, make analysis to filter weld pool, storage pool and steel tank liquor.

4. Quick census for superlarge range mine area to determine zone mode, draw mine map and timely prospect effectively.

5.Site quickly trace mineralized abnormality, seek hotspot zone and delineate ore boarder effectively.

6.Accurate analysis for millhead, concentrated ore and slag to build high efficiency mining and gathering process.

7.Through site analysis, mine field and grade control on material delivery, ore concentrate and slags, you can confirm or track the procedure validity of refining or concentration.

8.By time analysis several samples on the spot, you can guide exploration plan then manage excavation and explosion effectively.

9.Determine the geological composition of soil, sediment or drilling sample locally to control prospecting cost.

10.Apply with GIS/GPS to make detailed decision then can save much time and labor cost.

11. Multi-elements site fast analysis can be used in procedures in census and sift, then track mineral content abnormity and expand survey range. It can decrease samples amount sending to lab then save transportation and analysis cost.

12. Judge ore vein trend and mineral boundary then manage and control mining to detect mineral grade at any time.

13. Analyze rock core and other drilling samples quickly, then establish mine 3D graph to analyze composition, which can enhance site decision efficiency largely.

14. Analyze and test mine surrounding environment, slags, dust and soil pollution, then evaluate mine mountain condition renovation effect.

1. Exact grade evaluation for high grade and beneficiated ores, then provide value foundation for ore trade, processing and recycling.

2. The relict ore element analysis in slag and tails to rejudge the value.

3.Conduct QC in ore mining, boring, grinding, concentration and smelting, then confirm grade, make analysis to filter weld pool, storage pool and steel tank liquor.

4. Quick census for superlarge range mine area to determine zone mode, draw mine map and timely prospect effectively.

5.Site quickly trace mineralized abnormality, seek hotspot zone and delineate ore boarder effectively.

6.Accurate analysis for millhead, concentrated ore and slag to build high efficiency mining and gathering process.

7.Through site analysis, mine field and grade control on material delivery, ore concentrate and slags, you can confirm or track the procedure validity of refining or concentration.

8.By time analysis several samples on the spot, you can guide exploration plan then manage excavation and explosion effectively.

9.Determine the geological composition of soil, sediment or drilling sample locally to control prospecting cost.

10.Apply with GIS/GPS to make detailed decision then can save much time and labor cost.

11. Multi-elements site fast analysis can be used in procedures in census and sift, then track mineral content abnormity and expand survey range. It can decrease samples amount sending to lab then save transportation and analysis cost.

12. Judge ore vein trend and mineral boundary then manage and control mining to detect mineral grade at any time.

13. Analyze rock core and other drilling samples quickly, then establish mine 3D graph to analyze composition, which can enhance site decision efficiency largely.

14. Analyze and test mine surrounding environment, slags, dust and soil pollution, then evaluate mine mountain condition renovation effect.

Ø Instrument specification

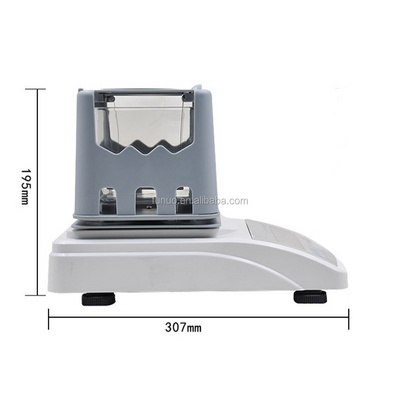

Weight

: 1.6Kg(with battery)

Dimensions : 254 x 79 x 280mm

Detector :BOOST Si-pin detector

The ARM architecture Cortex-A8 1 GHZ

System Processor :The Android 4.2 operating system/80MHZ ADC digitalpulse processor/4096 MCA channel , 32GB memory

Display : Industrial resistive touch screen with screen size of 4.3"

Data storage : Built-in 32gb memory, 300,000 spectral data and spectrumcan be stored

Operating Temperature : -20°C~+50°C

Operating Humidity : ≤90%

Limit of Detection : PPM

CPU : 1GB

RAM : 1GB

15 seconds reading time

GPS, WIFI : integrated into the system

Battery : lithium battery, which can be loaded with a maximum capacity of our 6800Ah can operate continuously for 8 hours; Equipped with high voltage (110V-220V) adapter, can work under current alternative

Sensor resolution : solid, liquid, powder

Sensor resolution : low resolution can be 139eV

Excitation source : 40KV / 100mA-Ag window miniature tube anode X of light and high voltage source

Collimator and filter : sights of 4.0 or 2.0 of diameter, automatic switch of 8 filter. 12 kinds of groups, plus mode consisting of world, can satisfy different types of tests of samples

Display : touchscreen TFT - LCD, resolution of 640 * 480.

Protection against water, dust and shock

Test window : 12mm.

Charging system gas : Helium charging system of ordinary pressure.

Security : standalone password manager mode.

Dimensions : 254 x 79 x 280mm

Detector :BOOST Si-pin detector

The ARM architecture Cortex-A8 1 GHZ

System Processor :The Android 4.2 operating system/80MHZ ADC digitalpulse processor/4096 MCA channel , 32GB memory

Display : Industrial resistive touch screen with screen size of 4.3"

Data storage : Built-in 32gb memory, 300,000 spectral data and spectrumcan be stored

Operating Temperature : -20°C~+50°C

Operating Humidity : ≤90%

Limit of Detection : PPM

CPU : 1GB

RAM : 1GB

15 seconds reading time

GPS, WIFI : integrated into the system

Battery : lithium battery, which can be loaded with a maximum capacity of our 6800Ah can operate continuously for 8 hours; Equipped with high voltage (110V-220V) adapter, can work under current alternative

Sensor resolution : solid, liquid, powder

Sensor resolution : low resolution can be 139eV

Excitation source : 40KV / 100mA-Ag window miniature tube anode X of light and high voltage source

Collimator and filter : sights of 4.0 or 2.0 of diameter, automatic switch of 8 filter. 12 kinds of groups, plus mode consisting of world, can satisfy different types of tests of samples

Display : touchscreen TFT - LCD, resolution of 640 * 480.

Protection against water, dust and shock

Test window : 12mm.

Charging system gas : Helium charging system of ordinary pressure.

Security : standalone password manager mode.

Data transmission

: digital multi-channel technology, the transmission of data SPI, a quick scan, count rate, waterproof miniature USB, which can be connected to the desktop computer.

Ø XRF-TrueX radiation safety

Radiation Safety Guarantee

Low power (4W) X-ray tube, mini collimator reduce radiation quantity effectively;

X-ray tube radiation protection shield avoids X-ray escape;

The structure producing radiation is all in equipment interior, you don't need to align or calibrate X ray, then ensure not detect

any measurable radiation in equipment operation process;

X ray indicator light alarms user the radiation produciton;

Independent safe circuit and DoubleBeam interlock tool can protect user safety effectively;

Conform to dosage limit requirement in (GBZ115-2002);

Conform to valid annual dosage limit requirement for workers and public in (GB18871-2002)

Ø After service

1. Quality warranty:

We commits that TrueX handheld spectrometer is fabricated with fine grade materials and

top notch workmanship. It is brand new, never used, and in full compliance with the quality provision of this Contract. TrueX warranty is 12 months starting from the date of final acceptance of the goods /commissioning of machine.

2. Technical training:

Operating Manual of TrueX Handheld Spectrometers

Maintenance Manual of TrueX Handheld Spectrometers

3. After-sale service

Over the years, Drawell has sold XRF instruments to many global users. In order to provide better technical support and service, it shall be committed to.

1. services including

a) provide after-sales service to all products it has sold worldwide.

b) provide a one-year warranty for the spectrometer it has sold worldwide.

c) provide one-year warranty for X-ray Tube (X-ray tube)and Detector (Detector).

d) provide one-year renewal warranty for the replaced components in case there is any replacement of them during repair of machine.

2. The following physical damage is not covered by warranty.

a) instrument is impacted by great force that the internal impact sensor changes from white to red;

b) Detector is broken

c) PDA is broken;

d) Instrument body is broken;

e) Loss of accessories

f) Loss of components

g) Water coming into instrument

3. In case the instrument is not able to operate, the customer can call after-sales service for help; we

offer 3 types of repairs:

a) Internet repair: if the customers are in foreign countries or remote areas, we can offer them first the INTERNET repair service.

b) Phone repair: customers called over the phone to explain explicitly the problem and our technical staff will instruct them to solve the problem.

c) On-site repair: in case the phone repair fails, our technical personnel will go to the site to repair the instrument within 72 hours after the problem is reported;

4. Out-of-warranty service: upon expiry of the warranty period, all customers are still entitled to out-of-warranty service during the working life of the instrument.

5. Privilege in out-of-warranty service: customers shall have the privilege to get a preferential prices on the components when they maintain their instrument during the out-of-warranty period as long as they maintained it beforehand.

We commits that TrueX handheld spectrometer is fabricated with fine grade materials and

top notch workmanship. It is brand new, never used, and in full compliance with the quality provision of this Contract. TrueX warranty is 12 months starting from the date of final acceptance of the goods /commissioning of machine.

2. Technical training:

Operating Manual of TrueX Handheld Spectrometers

Maintenance Manual of TrueX Handheld Spectrometers

3. After-sale service

Over the years, Drawell has sold XRF instruments to many global users. In order to provide better technical support and service, it shall be committed to.

1. services including

a) provide after-sales service to all products it has sold worldwide.

b) provide a one-year warranty for the spectrometer it has sold worldwide.

c) provide one-year warranty for X-ray Tube (X-ray tube)and Detector (Detector).

d) provide one-year renewal warranty for the replaced components in case there is any replacement of them during repair of machine.

2. The following physical damage is not covered by warranty.

a) instrument is impacted by great force that the internal impact sensor changes from white to red;

b) Detector is broken

c) PDA is broken;

d) Instrument body is broken;

e) Loss of accessories

f) Loss of components

g) Water coming into instrument

3. In case the instrument is not able to operate, the customer can call after-sales service for help; we

offer 3 types of repairs:

a) Internet repair: if the customers are in foreign countries or remote areas, we can offer them first the INTERNET repair service.

b) Phone repair: customers called over the phone to explain explicitly the problem and our technical staff will instruct them to solve the problem.

c) On-site repair: in case the phone repair fails, our technical personnel will go to the site to repair the instrument within 72 hours after the problem is reported;

4. Out-of-warranty service: upon expiry of the warranty period, all customers are still entitled to out-of-warranty service during the working life of the instrument.

5. Privilege in out-of-warranty service: customers shall have the privilege to get a preferential prices on the components when they maintain their instrument during the out-of-warranty period as long as they maintained it beforehand.

FAQ

FAQ

1. Q: Are you a factory or trading company?

A: We are a factory.

A: We are a factory.

2. Q: MOQ?

A: We don't have MOQ limit, you can order any quantity you want.

If you need scales with your specification, logo, packing, etc, please negotiate with us.

A: We don't have MOQ limit, you can order any quantity you want.

If you need scales with your specification, logo, packing, etc, please negotiate with us.

3. Q: OEM service?

A: We can produce scales with your logo, brand, packing. MOQ is 100pcs/model.

A: We can produce scales with your logo, brand, packing. MOQ is 100pcs/model.

4. Q: Delivery date?

A: 2-3 days for sample, 15-20 days for 1000pcs, 30-35days for 40HQ.

A: 2-3 days for sample, 15-20 days for 1000pcs, 30-35days for 40HQ.

5. Q: Payment Method?

A: L/C at sight, T/T, Western Union and Paypal are all available.

30% deposit T/T in advance, rest against the Shipping Doc.

100% in advance for sample order.

A: L/C at sight, T/T, Western Union and Paypal are all available.

30% deposit T/T in advance, rest against the Shipping Doc.

100% in advance for sample order.

6. Q: Shipping?

A: a. International Experess: DHL/TNT/FEDEX/UPS (For sample)

b. By air (For sample orders.)

c. By sea (15-45days), port of loading: Shanghai

d. By domestic logistics to your forwarder. (2-3days)

A: a. International Experess: DHL/TNT/FEDEX/UPS (For sample)

b. By air (For sample orders.)

c. By sea (15-45days), port of loading: Shanghai

d. By domestic logistics to your forwarder. (2-3days)

Diamond Trade X Ray Detector Korea Purity Of Palladium Gemstone Tester 1 Thermo Amptech Gold Testing Machine Pistola Metales Oro

Hot Searches