NaN / 0

Automatic household plastic products making machine /plastic cup lid thermoforming machine

Get Latest Price

US$ 60000

≥1 Sets

US$ 31500

≥2 Sets

US$ 31000

≥3 Sets

US$ 30000

≥4 Sets

Quick Details

Max.Forming Height(mm):

100 mm

Forming Width (mm):

400 mm

Forming Length (mm):

600 mm

Production Speed(Cycles/min):

20

Product Details

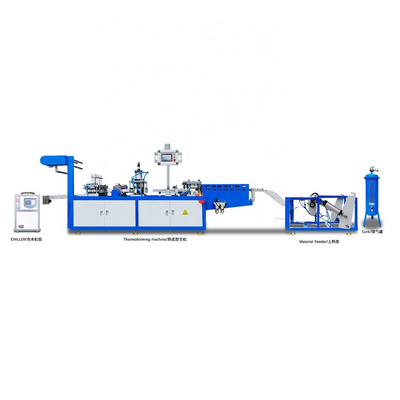

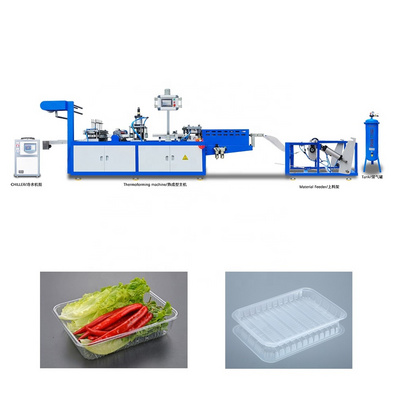

HX-640/500 Automatic Thermoforming machine for PP material

HX-500/600 series machines feature simple tool technology for forming,punching and stacking of thermoformed articles.with this technology sultable for PP material with high efficiency, high quality, less manpower, time-saving significant advantages.

HX-500 Thermoforming machine HX-640 Thermoforming Machine

HX-420 Thermoforming machine HX-420P Thermoforming Machine with safety cover

Parameter

|

Model |

HX-640 |

HX-500 | HX-420/420P |

|

Forming size(mm) |

600*400*70 |

550*350*50 |

420*200*50 |

|

Forming speed(cycles/min) |

20-30 |

15-25 |

15-25 |

|

Material |

PP,PS, PVC,PET,HIPS , GPPS |

PVC,PET,HIPS |

|

|

Material Width (mm) |

650 |

600 |

420 |

|

Material thickness (mm) |

0.25-1.8 |

0.25-1.8 | 0.25-0.8 |

|

Cutting Force(Ton) |

80 |

40 |

30 |

| Heating Type | Ceramic Heater | Metal heater | |

|

Power consumption(Kw) |

30 |

24 |

5 |

|

Mold cooling water |

Tap water or recycle water with 60L/h consumption |

/ | |

|

Machine Weight(Kg) |

5500 |

3200 |

2000 |

|

Machine Size (mm) |

L8500*W2000*H2000 |

L5500*W1500*H1900 |

L3000*W1000*H2000mm |

Features

1. The machine integrated, cutting, stacking, counting in one machine, with high efficiency, high quality, less manpower, time-saving significant advantages.

2. Adopt automatic feeding system, greatly reducing the labor intensity of workers.

3. Temperature control system is placed in the PLC program system, adjusted by direct touch screen, convenient and efficient.

4. Forming part of the upper and lower mold use cylinder to drive the rod drive, convenient and efficient.

5. Forming part of the upper and lower mold use cooling system interface, the product and the mold can rapidly cooling, so that production is higher.

6. Cutting part adopt the way of cylinder drive connecting rod drive,

7. Stacked part controlled by servo system, more stable, accurate and efficient.

8. The machine adopts the servo system to pull the film, so that the film and cut more accurate; chain guide with a special design, to ensure that the pull is not deviation.

9. Output structure adopts adjustable speed transmission belt, more stable and high efficiency.

10. Waste system adopts motor control, stable and convenient.

11. The machine has a program memory function, can store multiple production data, the next work can be transferred directly to the storage of production data, saving time and effort.

Configuration list

|

Switch button |

Germany, Schneider |

|

Controller |

Germany, Siemens |

|

PLC screen |

Germany, Siemens |

|

Miniature relay |

Germany, Schneider |

|

Encoder |

Germany |

|

Power switch |

Japanese, OMR |

|

Solid-state relay |

Japanese, OMR |

|

Servo motor |

Japanese, Panasonic |

|

Over-voltage & under- voltage protection |

China, Renmin |

|

Thermometer |

China, Huibang |

|

Binding post |

China |

|

Amplifier |

China |

|

Frequency converter |

China, Danfoss, |

|

Reduction gear |

China, Zhongda |

Factory

Shenzhen HuaXiang Factory Co. , Ltd is a diversified export-oriented enterprise integrated with technology, industry and trade. established in 2005, is the largest enterprise specializing in the production of Forming Machine. Our machine are used a lot in plastic forming,plastic packaging.

Machine recommend

Made in Taiwan, HX-1000 High-end Full Automatic Thermoforming/Vacuum Forming Machine

More about info please clieck our website below:

Contact

In order to help you choose the best suitable machine, please try to reply my questions below, thanks for your cooperation.

Q1: What about your material ?

Q2: The size of your sample; length Width and thickness?

WEBSITE: https://huaxiangjx.en.alibaba.com/

Hot Searches