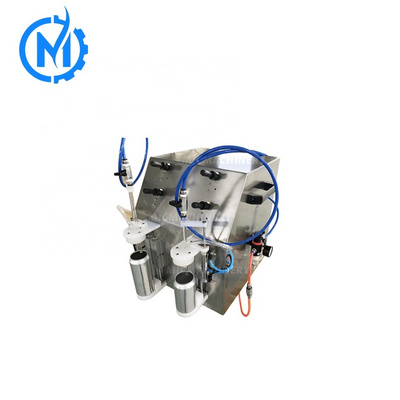

be accurate measurement of liquid nitrogen, precise join in cans or bottles.

Join in cans or bottles of liquid nitrogen can quickly heat gasification (into a gas), volume expansion, 700 times, ore will be on the top of the iar / bottle oxygen out, two inner pressure. Completely solved the problem of the dented cans / bottles.