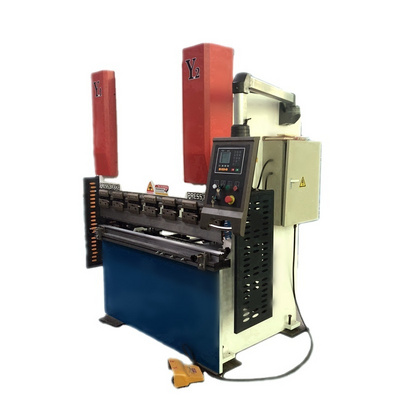

E21 System

- HD LCD screen;Available in both Chinese and English; Available in two units of mm/inch;

- The programming parameters are displayed on one page, making it faster and more convenient to write programs;

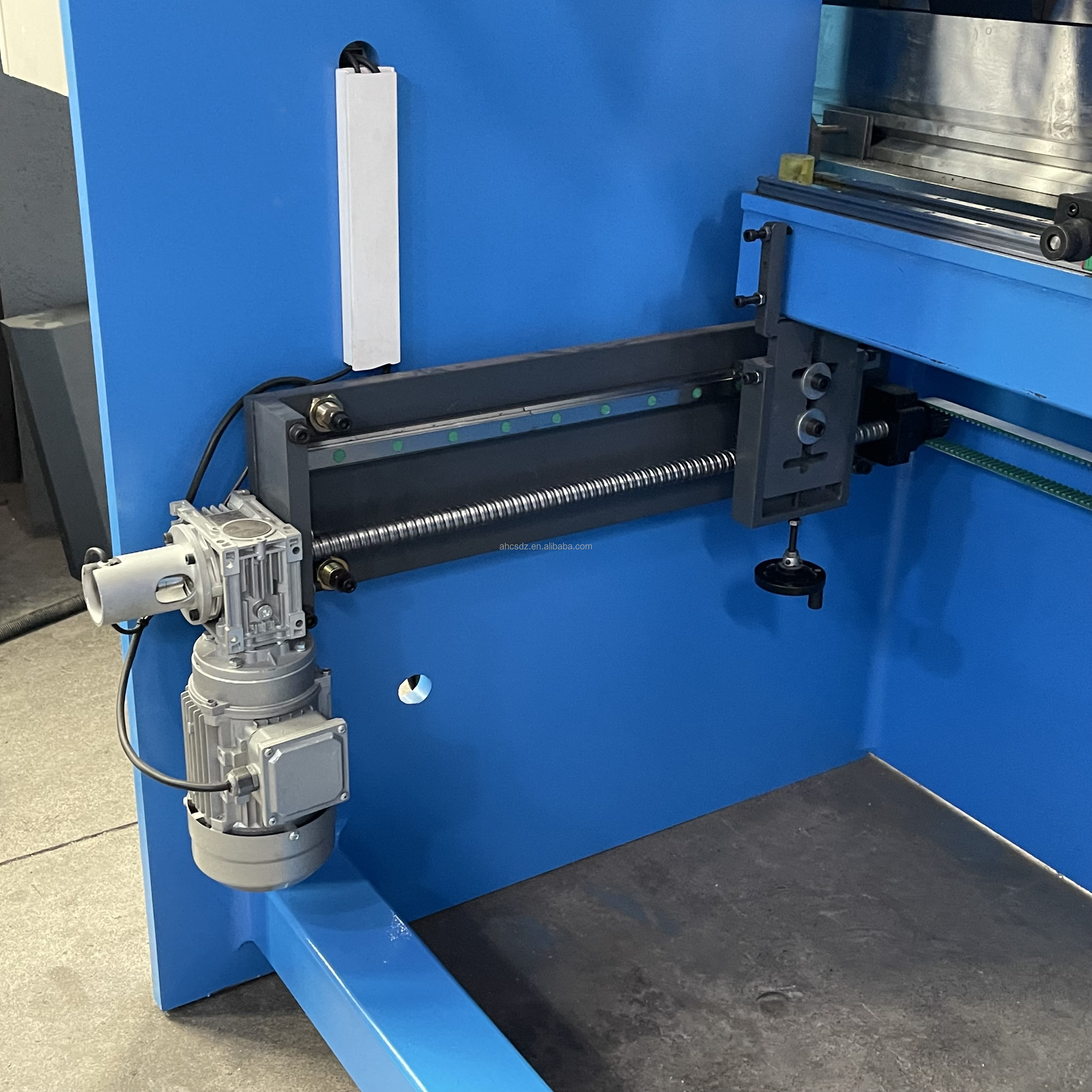

- X, Y axis intelligent positioning, can also be manually adjusted according to needs, remove the mechanical manual positioning device;

- Backgauge control, the control is general AC motor, frequency conversion speed regulation;

- Built-in pressure holding time and unloading delay setting functions, the operation is more convenient, no time relay is needed, and the cost is reduced;

- With one-key backup and restore function of parameters, parameters can be restored at any time as needed, reducing maintenance costs;

- Support multi-step programming, complex workpieces can be processed at one time, improving production efficiency and machining accuracy,

- All the buttons on the panel are micro switches, which have been strictly tested by EMC, high and low temperature,

vibration, etc. to ensure the stability and service life of the product;

- Passed CE certification to meet the needs of overseas markets.