NaN / 0

facial tissue paper packing manufacturing machines / production line / converting machine

Get Latest Price

US$ 1000

≥1 Sets

Quick Details

Production Capacity:

1800pcs/min

Place of Origin:

Henan, China

Brand Name:

Shengfeng

Voltage:

220v/380v

Product Details

Product Description

Brieft Description of Facial Tissue Paper Machine

In the first process, the paper extractor folds out the finished paper

The box / soft towel machine is a rectangular paper folding machine which cuts the original knife roller and folds it into a hinged chain type rectangle. This machine adopts vacuum suction and automatic counting and stacking device, which has the advantages of fast speed and accurate quantity.

This type of tissue paper machine adopts synchronous belt transmission and transmission speed ratio before and after transmission, so that the equipment can meet the needs of a variety of base paper and greatly improve the quality and efficiency. Main features:

1. Pneumatic steel to steel embossing and pneumatic separation;

2. The paper withdrawing frame adopts pneumatic paper feeding, stepless speed change, speed ratio adjustment and different paper tension adjustment;

3. Roots vacuum pump adsorption system is adopted, which has large suction capacity and stable operation;

4. The finished products with different widths can be folded according to the needs, and point cutting or full cutting can be selected;

5. Steel to steel embossing device can be selected to ensure that the double-layer tissue paper is not layered;

6. Base paper alignment function can be configured as required;

7. The front and rear inching switch is used to pull the base paper, which is easier and safer to operate.

Specification

|

Model

|

180/3rows

|

|

Maximum Width of Paper

|

560mm

|

|

Maximum diameter of paper

|

1300mm

|

|

Inner diameter of paper core

|

76.2mm

|

|

Paper size of finished Product

|

180 * 220, 180 * 210, 180 * 180, 180 * 175 etc

|

|

Folding size of finished Product

|

90 * 220, 90 * 210, 90 * 18, 90 * 175 etc

|

Second Process

In the second process, the small rotary paper cutter cuts out a small portion of paper

High speed small rotary paper cutter is one of the automatic cutting lines for toilet paper, tissue paper and kitchen paper

The machine adopts frequency conversion speed regulation, servo tracking control, PLC programming control, light, electricity, gas integration automatic control system, man-machine interface is convenient for operation, flexible change of grinding time, cutting speed, cutting length. The safety of equipment protection is strong.

It can cut 150 pieces of paper per minute, which can greatly improve the processing line and production efficiency. The whole machine mechanism is solid, the design is beautiful, the paper cutting action is accurate, the efficiency is high, the facial tissue cut surface is smooth and smooth.

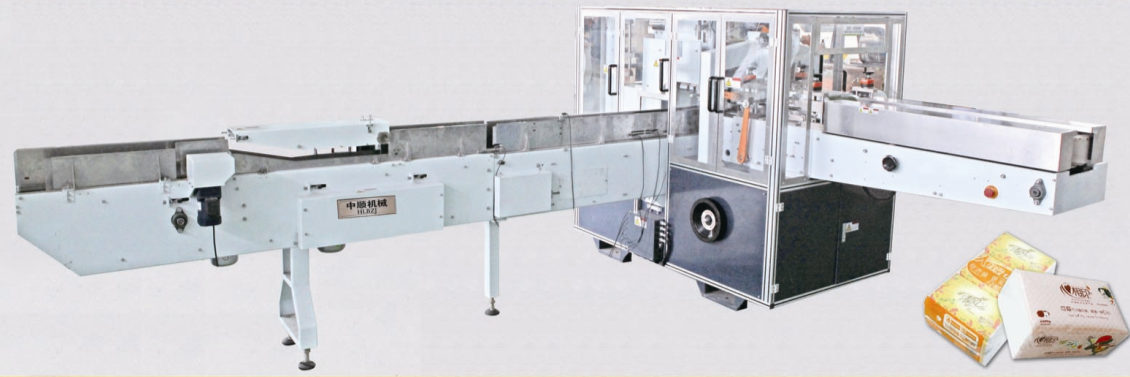

Third Process

The third process, automatic three-dimensional packaging machine packaging finished products small parts of paper

Automatic soft paper drawing packaging machine

Scope of application:

It is suitable for the outer packing of regular tetragonal objects such as paper towel and paper box with good sealing performance.

Main performance and structural features:

1. The packaging forms of wrapping, folding and edge sealing are adopted, with compact structure and beautiful appearance. It is suitable for the outer packaging of regular tetragonal objects such as paper towel and paper box with low sealing requirements.

2. Adopt frequency conversion stepless speed regulation control system, touch screen and PLC control system. The display of man-machine interface is clearer and the maintenance is easier.

3. The automatic material handling and conveying tailstock is adopted, which is convenient to connect with the automatic production line, and the labor cost is more obvious.

4. Double frequency stepless speed regulation, packaging speed and bag length can be adjusted at will.

5. High degree of automation, strong specialization, high production efficiency and low failure rate.

6. The packaging range is large, and fast conversion can be realized between various specifications and sizes.

Packing & Delivery

1.The dryer is packed with wood chips for protecting its surface

2. The large diameter roll is packed with wood chips.

3. The steel rolls are packed with plastic film and straw ropes

4. Speed reducer, oil station, and suction box, hydraulic station is packed with wooden box.

5. Electric control cabinet is packed with three-ply board box

6. Some parts are nude cargo

Hot Searches