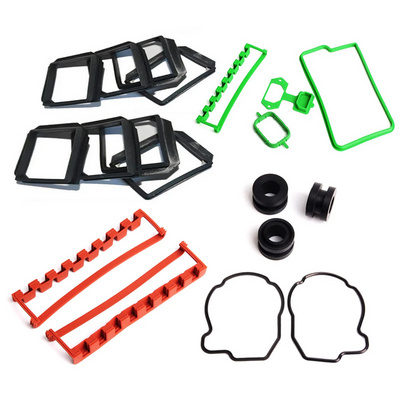

Anti-vibration, cushioning, sealing, pressure relief, high temperature resistance, flame retardant, tear resistant

Strong sealing,dust-proof,moisture-proof,air-tight,light-blocking,vibration isolation,fire prevention.

Can work in the air or oil medium at the temperature of -50~+230℃.