NaN / 0

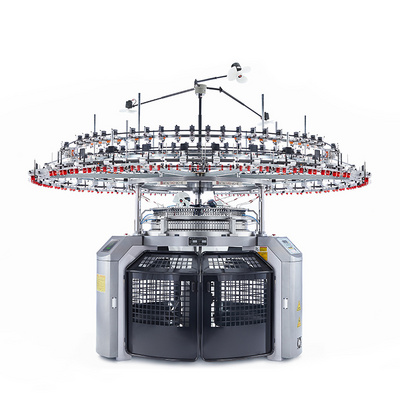

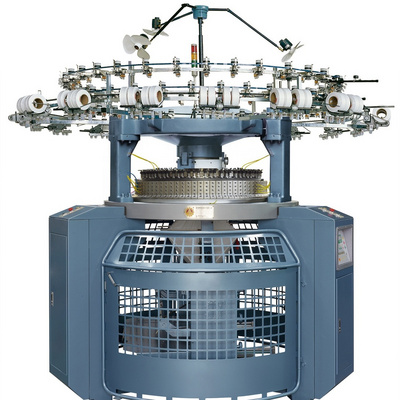

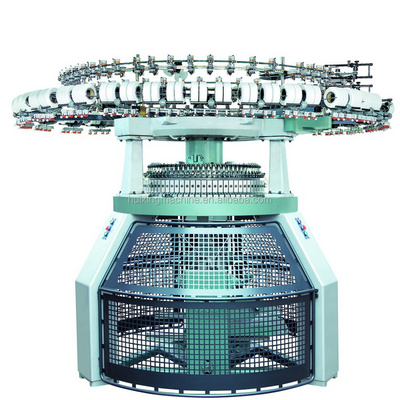

New Style Double Jersey Circular Knitting Machine

Get Latest Price

US$ 10000

≥1 Sets

Quick Details

Type:

Circular

Production Capacity:

100%

Knitting Style:

Weft

Knitting Method:

Double

Product Details

Product Description

New Style Double Jersey Circular Knitting Machine

Brand new frame structure design and well matched installation preocess slimainating the produstion stress amd defromation during installation, improve the stiffness and stability of machine frame to a new height.

opetimize transmission relation to make it comply with the specificationof machinery design, so as to reduce the wear of transmission and section.

the running precision, impact resistance and drive energy consumption of reel bear can reach a greatly enhance, on the base of using the four-point contact bearing principle and german fine grinding steel wire and steel ball. therfore, 34'' machine only needs the motor of 3.0KW to be driven easily.

Brand new structure of the central lifting system, structure is simple, high precision. Easy to operate, making the lifting error within 0.03mm.

Aviation aluminum cam stand snjoys light weight, high strength, non-deformation, can effectively reduce can plate deformation due to cam stand overweight.

The micro-adjustable system of cam adots archimedes spiral structure to enable a high adjustment precision, match high precison cam box and frame, preciselyreflecting sinking depth through the values on the dial.

With the innovation of fixing method, sinker of single knitting machine and feeder ring eliminating deformation during the installation process, making it at the stretched and natural condition. and this idea runs through the design idea of the whole machine.

The double-shaft linkage structure of double knitting machine eliminates the asynchronous phenomenon between top and bottom hand discs, caused by tooth mesh clearance.

The new connection way between double knitting machine big tripod and medium pile footing eliminates the production stress deforamtion and overcomes displacement phenomenon during transportation.

The connection way of dial cam stand and needle tray adopts and adjustable silk structure, easily to adjustment part and mechanical rotation part of double knitting machine can avoid the influence on the stabilization of transmission when adjusting needle distance.

The innovated belt puller device changed motor fixed method and solved the vibration caused by between mator and frame.

Main Features

New Style Double Jersey Circular Knitting Machine

1) Machine is equipped with roller-shifting device, which ensure density of whole fabric to be even and stable.

2)Machine is equipped with motorized cuter, high efficiency and easy to maintain.

3)Equipped with latest winder, fabric can be winded synchronized with even tension.

4) Folding mark is avoided effectively which comes in common winders, so it's good for making fabric with spandex yarn.

5) Quality and usage of fabric are increased, and subsequent finishing process is simplified.

Detailed Images

Devices& Equipment

A: Japanese stainless steel cylinder

B: Well designed sturdy machine frame

C: Wire bearing supported main drive system

D: Central and individual stitch length adjustment facility

E: Groz-Beckert/HuiXing Needles(Germany/China)

F: HuiXing Sinkers (China)

G: Invertor (Taiwan & Chinese Brand)

H: Electronic Motor(Taiwan & Chinese Brand)

I: Fabric taken down system(2 way rolling & Folding)

J: Centeral Control Panel(Taiwan & Chinese Brand)

K:Oiler or lubricator(Taiwan & Chinese)

L: Positive yarn feeder(Germany Memminger & Chinese Brand)

M: Lycra yarn feeder(Germany Memminger & Chinese Brand)

N: Floor Creel & Tube Creel

O: 360 degree radar cleaning system(Taiwan)

P: Full set of cams (for each track)

Q: Anti-Dust Device

R: A well equipped standard tool box

Packing & Delivery

Our Service

Pre-Sales Service

* Tour our Factory.

* Inquiry and consulting support.

After-Sales Service

* Operation manual and installation instructions

* We offer one year warranty for the customer

Related Products

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Hot Searches