NaN / 0

Automatic Electric Industrial Pasta Extruder Production Line Making Spaghetti Machine

Get Latest Price

US$ 30000

≥1 Sets

Quick Details

Applicable Industries:

Pasta Factory

Production Capacity:

50-300kg/h

Place of Origin:

Shandong, China

Brand Name:

Joyang

Product Details

Fully Automatic Fusili Penne Extrusion Machine Pasta Production Line

Product Description

Product Description

Pasta production lines use wheat flour, cornflour, potato flour as main materials, through mixing, extruding, cutting, and drying to make different shapes of pasta, like a shell, screw, tube, etc. Machine configuration is perfect, advanced production technology, good quality products, simple and reliable, it's the ideal machine to make pasta.

We can not only supply a complete pasta production line but also supply a pasta packaging machine.

Product Parameters

Product Parameters

| Model | Installed Power | Power Consumption | Production Capacity | Dimension |

| JY-100 | 86 kw | 58 kw | 100kg/h | 18×2 ×2.5m |

| JY-150 | 98 kw | 68 kw | 150kg/h | 20.5 ×2×2.5m |

| JY-200 | 120 kw | 84 kw | 200kg/h | 21 ×2.5×2.5m |

Product Detail

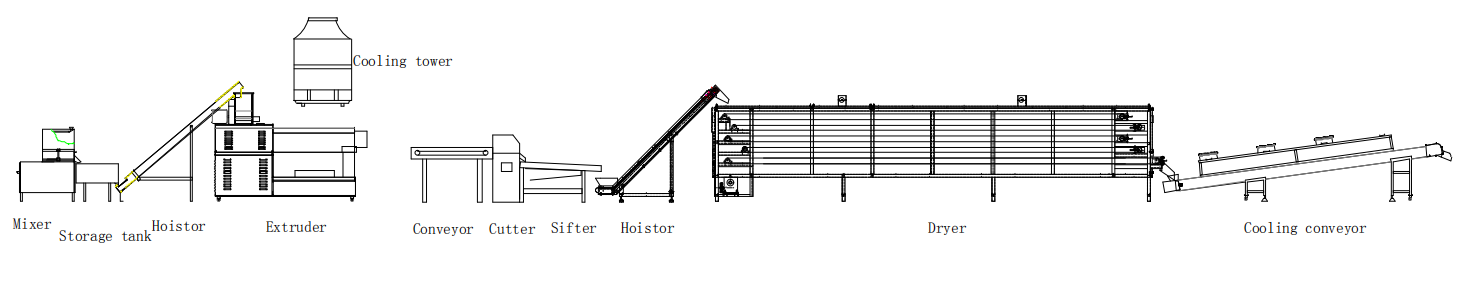

Flowchart Diagram

Machine List In The Macaroni Processing Line

Mixer → Storage Tank → Hoister → Single Srew Extruder → Cooling Tower → Conveyor → Cutter → Sifter → Hoister → Dryer → Cooling Conveyor

|

Mixer

|

It is a mixer that can mix all the raw materials (powder form) with water and liquid chemical additives. |

|

Storage Tank

|

The pasta raw material moisture is high, and the storage tank is equipped with stirring fins, which can prevent the raw material do not sticky, and also cache the role of raw materials, which can improve efficiency. |

|

Hoister

|

The mixed materials can be conveyed to the feeding machine (feeder) of the extruder. |

|

Single Screw Extruder

|

The single-screw extruder is made of the feeding system, extruding system, cutting system, heating system, transmission system, cooling system, and controlling system. The machine barrel adopts the heating and the water-cooling controlling temperature; it has a stable temperature and high-quality products. |

|

Cooling Tower

|

The cooling tower is used to control the temperature of the extruder. |

|

Conveyor and Long Cutter

|

This conveyor is for long cutting. The cutting speed and length can be adjustable. The cutter is for cutting pasta and macaroni etc. The cutting speed and length can be adjustable. |

|

Sifter

|

It will shake all products by vibration motor, to avoid all products sticking together. And it will cool down the products during the transfer process. |

|

Dryer

|

The multi-layer is with a compact design which can make the food be well dried in a limited space. We can adjust the number of layers and lengths depending on the output of the oven. It is a food standard stainless steel belt. The temp of the dryer and the drying time can both be controlled. We can also provide a gas dryer, diesel dryer, and steam dryer, or even a double energy dryer. |

|

Cooling Conveyor

|

It is used to cool the products, the length is 6 meters, and can convey the products to the packing workshop. |

Customer And Service

Customer & Service

We exported the machines to many countries all around the world, such as Italy, Germany, Russia, Turkey, Australia, Indonesia, India, etc. Almost all the customers speak highly of our machines and service, and they continue to buy from us again and again.

Service

1. One-year complete warranty.

2. Free consultation service before during and after-sales.

3. Provide basic production techniques and formulas.

4. Overseas installation and training of equipment maintenance and operating personally.

5. Debugging and inspecting of equipment until everything is functional before leaving the factory.

Hot Searches