NaN / 0

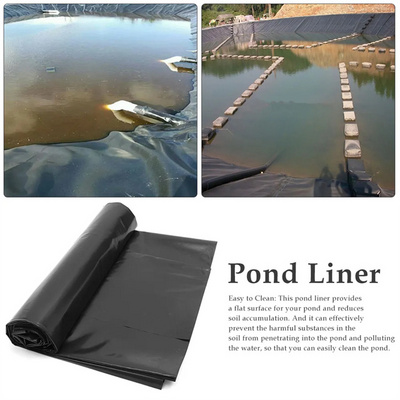

HDPE Geomembrane Dam Liner 1mm 2mm Polyethylene Geomembrane Welders Fish Tank Farm

Get Latest Price

US$ 1.69

≥100 Square meters

US$ 1.29

≥500 Square meters

US$ 0.99

≥1000 Square meters

US$ 0.59

≥3000 Square meters

Quick Details

Warranty:

More than 5 years

After-sale Service:

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection

Project Solution Capability:

total solution for projects, Cross Categories Consolidation

Application:

Farmhouse

Product Details

HDPE Geomembrane Liners

High-Density Polyethylene (HDPE) is characterized by strong UV/ temperature resistance, inexpensive material cost, durability, and high resistance to chemicals.

It is the most commonly used geomembrane because it offers higher thickness which other geomembranes don’t. HDPE is the preferred choice for pond and canal lining projects, landfill, and reservoir covers. Thanks to its chemical resistance, HDPE can be used in storing potable water.

It is the most commonly used geomembrane because it offers higher thickness which other geomembranes don’t. HDPE is the preferred choice for pond and canal lining projects, landfill, and reservoir covers. Thanks to its chemical resistance, HDPE can be used in storing potable water.

Products Description

|

Item

|

Value

|

|

|

|

|

|

|

||||||

|

Thickness, ( mm )

|

0.75

|

1.0

|

1.25

|

1.5

|

2.0

|

2.5

|

3.0

|

||||||

|

Density, ( g/cm3 )

|

≥0.94

|

|

|

|

|

|

|

||||||

|

Tensile yiedl strength, ( N/mm )

|

≥11

|

≥15

|

≥18

|

≥22

|

≥29

|

≥37

|

≥44

|

||||||

|

Tensile breaking strength, ( N/mm )

|

≥20

|

≥27

|

≥33

|

≥40

|

≥53

|

≥67

|

≥80

|

||||||

|

Elongation at yield, ( % )

|

≥12

|

|

|

|

|

|

|

||||||

|

Elongation at break, ( % )

|

≥700

|

|

|

|

|

|

|

||||||

|

Tear Resistance, ( N )

|

≥93

|

≥125

|

≥160

|

≥190

|

≥250

|

≥315

|

≥375

|

||||||

|

Puncture Resistance, ( N )

|

≥240

|

≥320

|

≥400

|

≥480

|

≥640

|

≥800

|

≥960

|

||||||

|

Stress Crack Resistance, ( h )

|

≥300

|

|

|

|

|

|

|

||||||

|

Carbon Black Content, ( % )

|

2.0-3.0

|

|

|

|

|

|

|

||||||

|

Carbon Black Dispersion

|

1 or 2

|

|

|

|

|

|

|

||||||

|

Standard OIT, ( min )

|

≥100

|

|

|

|

|

|

|

||||||

|

High Pressure OIT, ( min )

|

≥400

|

|

|

|

|

|

|

||||||

HDPE Lining materials are a cost effective choice for exposed lining projects because the geomembrane is UV stable and requires no soil cover. This product has been used in landfills, WWT lagoons, animal waste lagoons and mining applications due to its high chemical resistance. HDPE geomembrane can be bonded via a wedge weld or fusion weld to create a strong and seamless system. The range in available thicknesses, from 40 mil to 120 mil, allow the technology to suit many applications.

Frozen, pooling, flowing, wastewater, and standing liquids can be hazardous if not properly managed. Hence, geomembranes are used to prevent the loss of material. The following are uses of geomembranes: As liners for various waste conveyance canals As waterproofing liners within tunnels and pipelines As liners for the agriculture industry As liners for potable or reserve water (for example, safe shutdown of nuclear facilities) To contain and transport potable water and other liquids in the ocean As liners

for the agriculture industry As fish pond liners Beneath highways to prevent pollution from deicing salts As liners for primary, secondary, or/and tertiary waste piles and solid-waste landfills Adjacent and beneath highways to capture hazardous liquid spills As liners for sewage sludge, radioactive or hazardous waste liquid As linings for emergency spillways To contain and transport liquids in trucks

for the agriculture industry As fish pond liners Beneath highways to prevent pollution from deicing salts As liners for primary, secondary, or/and tertiary waste piles and solid-waste landfills Adjacent and beneath highways to capture hazardous liquid spills As liners for sewage sludge, radioactive or hazardous waste liquid As linings for emergency spillways To contain and transport liquids in trucks

Hot Searches