NaN / 0

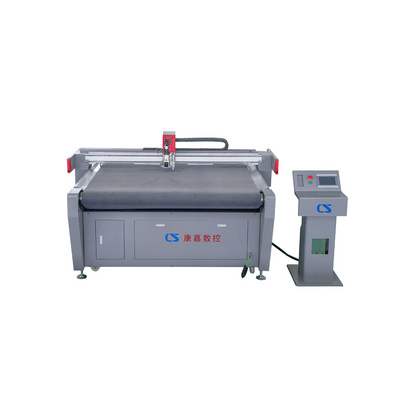

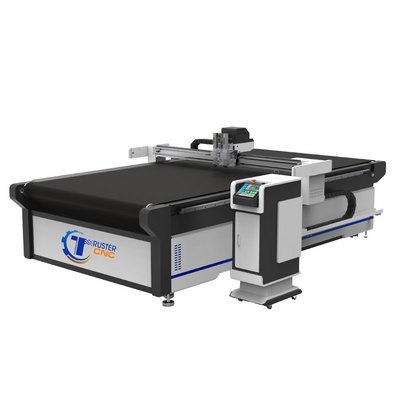

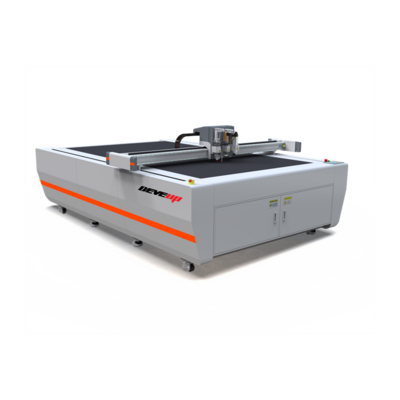

CNC Knife Cutter Automatic Gasket Making Digital Cutting Machine for Rubber Graphite Non Asbestos Silicon PTFE Sealing Gaskets

Get Latest Price

US$ 11600

≥1 Sets

US$ 9600

≥10 Sets

Quick Details

Cutting Speed(m/min):

0 - 30 m/min

Max.Product Size(L)(mm):

2500 mm

Max.Product Size(W)(mm):

1600 mm

Max.Product Size(H)(mm):

50 mm

Product Details

Product Description

Deveup CNC gasket cutting machine is mainly used in the sealing industry for automatic intelligent cutting of various sealing gaskets, including non asbestos gasket, asbestos rubber gasket, graphite composite gasket, rubber gasket, PTFE gaskets, and etc. The reasonable and advanced mechanical structure design and the CAM special software developed for the sealing industry promote our cutting machine to complete the special-shaped processing of sealing parts with high precision, high speed and more stability. The finished workpiece is free of sawtooth, burr, smooth and consistent, effectively solving the aging of sealing industry practitioners, low production efficiency, dependence on labor experience, low material utilization rate, and the difficulty in manufacturing special-shaped parts and non-standard specifications Chaotic document management, high product scrap rate, long delivery cycle and other problems help customers in the sealing industry win more market share with high-quality, short production cycle and customized customer service while reducing costs and improving efficiency!

Compared with traditional die punching and CO2 laser cutting, our intelligent digital cutting machine does not need a die, saving time and effort. It features accurate sample cutting, smooth edges, no serrations, no yellowing and charring, no powder foam, smoke, odor, safety, environmental protection, easy maintenance, and low cost. Users can also choose large vision systems, projectors, dual heads, and lengthen and widen the working area of the cutting bed, To meet different personalized production needs.

Compared with traditional die punching and CO2 laser cutting, our intelligent digital cutting machine does not need a die, saving time and effort. It features accurate sample cutting, smooth edges, no serrations, no yellowing and charring, no powder foam, smoke, odor, safety, environmental protection, easy maintenance, and low cost. Users can also choose large vision systems, projectors, dual heads, and lengthen and widen the working area of the cutting bed, To meet different personalized production needs.

Specification

|

Parameters/Model

|

FV1216 FV1625 FV1830 FV1650

|

|

Cutting Size

|

1200x1600mm 1600x2500mm 1800x3000mm 1600x5000mm

|

|

Cutting Thickness

|

≤45mm (Other thickness can be customized according to the material)

|

|

Cutting Speed

|

≤1700mm/s(The actual speed depends on the material and cutting graphics)

|

|

Applicable materials

|

Rubber, Cork, Felt, Foam, Asbestos, Non-asbestos, PTFE, Graphite, other non-metal gasket materials

|

|

Cutting precision

|

± 0.1mm

|

|

Repeat accuracy

|

≤3mm Diameter

|

|

Positioning way

|

Laser positioning also optional CCD camera positioning

|

|

Safety device

|

Physical anti-collision mechanism + infrared induction anti-collision to ensure production safety

|

|

Material fixed way

|

Vacuum adsorption

|

|

Transport interface

|

Ethernet front-end ports/usb

|

|

Compatible software

|

AI software, AutoCAD, CorelDRAW, and all of the box type design software can output directly, without conversion, and with automatic optimization

|

|

Support File Format

|

DWG, AI, PLT, DXF

|

|

Operation Panel

|

Multilingual languages LCD touch panel

|

|

Transmission system

|

High precision linear guide, meshing transmission gear and rack structure, Japanese Panasonic high performance servo drive motors + precision reducer

|

|

Power supply voltage

|

AC 220 v to 380 v ± 10%, 50 - 60hz

|

|

Pump power

|

7.5kw/9kw/11kw

|

|

Work environment

|

Temperature: - 10 ºC to 40 ºC, humidity: 20% ~ 80% RH

|

|

Dimension(L*W*H)

|

3.5x2.2x1.3m

|

|

Weight

|

1400KG

|

Machine Details

Colorful LCD touch operation panel supports world multilingual kinds of languages, with more intuitive operation interface, which can directly input processing data, set processing speed and knife depth, support screen automatic protection, and protect

processing data,feature-rich and user-friendly operation.

processing data,feature-rich and user-friendly operation.

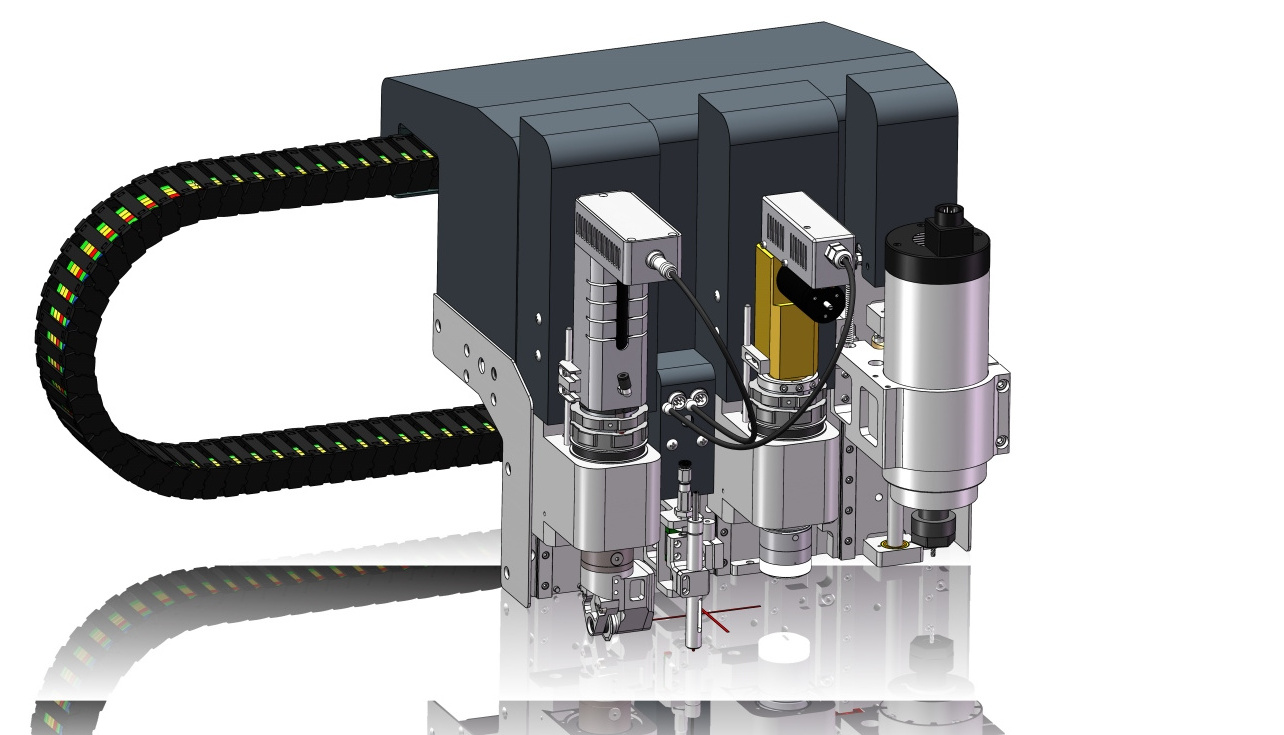

A variety of tool combinations, equipped with intelligent tools interchange system, can cut different materials to achieve different tasks, and multiple tool heads can work individually or in concert. Powerful function, fast running speed, high

processing accuracy, truly multi-purpose machine.

processing accuracy, truly multi-purpose machine.

We use CNC gantry machining center for planing and milling machine shelf. Our bed has the characteristics of heavy weight, good load-bearing capacity, higher precision, and high hardness, which ensures the accuracy and stability of the oscillating knife cutting machine at high speed. We guarantee that the machine will not be deformed in 10 years.

The beam adopts the extrusion process of aviation aluminum alloy die, which ensures the stability and high precision of machine operation at high speed, especially suitable for some industries that require high precision, such as sealing gaskets

Imported famous brand helical gear rack, quenching and hardening treatment. High precision, strong load-bearing capacity, smooth

running at high speed and less noise.

running at high speed and less noise.

Imported PMI 20mm high precision linear guide, high positioning accuracy, high repeatability. Low friction resistance, high rigidity four-way load design, high speed and long time operation to maintain high precision

Safety protection device. Highly sensitive collision avoidance system and red light brake system. When the machine is cutting at high speed, it can effectively protect safety of the operator.

The worktable is a high precision and strength aluminum honeycomb vacuum absorption worktable. Cooperate with high power vacuum pump to fix the material.

Imported Holland 4mm felt with built-in fiber tensile layer to protect the vacuum table and blades while the machine is working. Cutting-resistant, soft, won't scratch the product, non-slip, prevent the material from shifting during the cutting process.

High power vacuum pump to fix material. The vacuum pump runs automatically when the machine is working.

Use top quality Japan Panasonic servo motors and drivers(X-axis double servo motor driving + precision reducer drive). Strong power, long life, and high precision.

Cutting software is feature-rich, supports multi-language, friendly operation, and has automatic optimization nesting function, which can help customers save raw materials to the greatest extent.

Tools Introduction

Cutting Samples

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

1. Q: Are you a factory or Trading company?

A: We are a professional oscillating knife cutting machine production factory, we produce high-end quality CNC cutting machines.

2. Q: Can you customize the machine according to my needs?

A: Yes, we accept the customized machine, our company has an experienced professional design team, we can give you our professional suggestions according to your requirements and design a cost-effective machine for your needs.

3. Q: What is the difference between this knife cutting product and your laser cutting machine?

A: a. This knife cutting machine cut with vibrating blades, no laser, no pollution, and create a good working environment for

workers.

b. Blade cutting can ensure the edge of material cutting smooth without burning.

4. Q: What's the warranty policy?

A:Standard warranty is 36 months upon delivery.

Main parts are free of charge(except consumable parts) when problems happened because of quality problem during this period. Problems caused by wrong operate will also well-solved.

5. Q: Can I still get support after warranty?

A: Of course, We offers life-time technology support, you can always counting on our service.

6. Q: This is the first time I buy machine from China, what can you do for me?

A: We supply DDU service for the new buyers. This service means we will deliver machine directly to your factory.

A: We are a professional oscillating knife cutting machine production factory, we produce high-end quality CNC cutting machines.

2. Q: Can you customize the machine according to my needs?

A: Yes, we accept the customized machine, our company has an experienced professional design team, we can give you our professional suggestions according to your requirements and design a cost-effective machine for your needs.

3. Q: What is the difference between this knife cutting product and your laser cutting machine?

A: a. This knife cutting machine cut with vibrating blades, no laser, no pollution, and create a good working environment for

workers.

b. Blade cutting can ensure the edge of material cutting smooth without burning.

4. Q: What's the warranty policy?

A:Standard warranty is 36 months upon delivery.

Main parts are free of charge(except consumable parts) when problems happened because of quality problem during this period. Problems caused by wrong operate will also well-solved.

5. Q: Can I still get support after warranty?

A: Of course, We offers life-time technology support, you can always counting on our service.

6. Q: This is the first time I buy machine from China, what can you do for me?

A: We supply DDU service for the new buyers. This service means we will deliver machine directly to your factory.

Hot Searches