NaN / 0

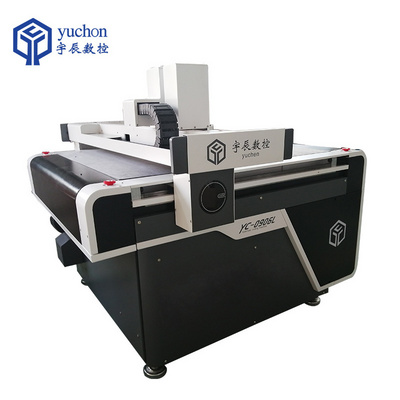

cnc cardboard box carton cutting machine

Get Latest Price

US$ 12000

≥1 Sets

US$ 7000

≥3 Sets

Quick Details

Type:

Paper Cutting Machine

Production Capacity:

800-1600mm/s

Max. workable width:

600mm

Place of Origin:

Shandong, China

Product Details

cnc cardboard box carton cutting machine

Product detials

It has the following functions:

- auto sheet loading and receiving

- CCD camera registration system for precise cutting

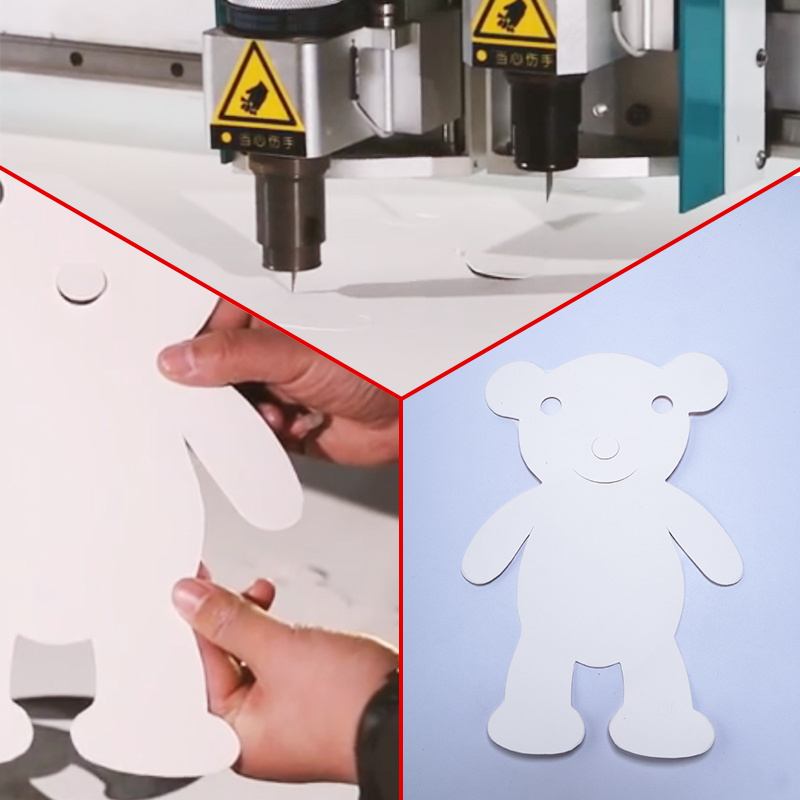

- drag cut, kiss-cut, creasing and drawing in one pass

- Intelligentize control and easy to operate

- Exact cutting size and high cutting speed

-

it can read QR code to cut

| Model | AOL-6090 |

| Processing Area | 600*900mm |

| Interface | USB/Enternet port |

| Cutting Speed | 200-1400mm/s |

| Format | PLT/DXF |

| Total Power | 11kw |

| Repeatability | 0.05mm |

| Cutting Thickness | 50mm |

| Material Fixing | Vacuum Partittion Adsorption |

| Multi-function tool | Vibrating knife full cut, semi-cutting cut, indentation, drawing mark, cursor positioning, camera positioning edge cutting, high power active round knife |

| safety devices | Use infrared sensing, safe and reliable |

| Applicable materials | Knitting, woven, fur (sheep shearing), PU leather, oxford cloth, canvas, sponge, imitation leather, cotton linen, blended fabric etc. All kinds of clothing, bags, sofa fabrics and carpet fabric etc |

| Transmission system | Yaskawa servo motor, linear linear guide, timing belt, lead screw |

Advantage

High frequency electric oscillating/vibration knife: There would be much more cutting

material and cutting thickness to meet different demands of customers.

Precise auto-positioning system: Equipped with HD CCD camera, it could achieve the precise auto-positioning of all materials and the automatic registering, which solves the imprecise manual positioning and the deforming printing, so as to reach the simple and precise cutting.

Barcode management system: Scan the barcode to read the cutting task rapidly.

Automatic feeding system: Automatic feeding system to make the cutting more efficient.

Buyer Feedback

Packaging & Shipping

Hot Searches