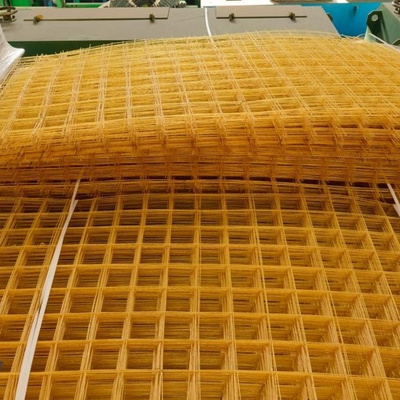

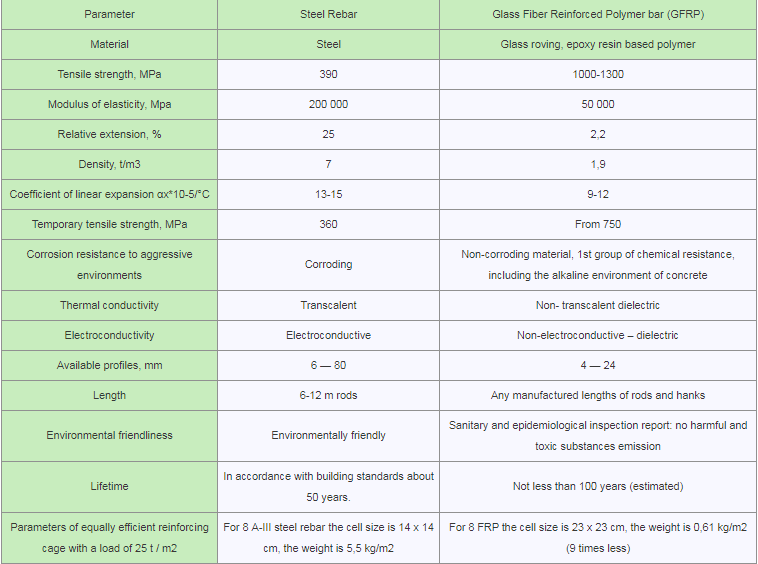

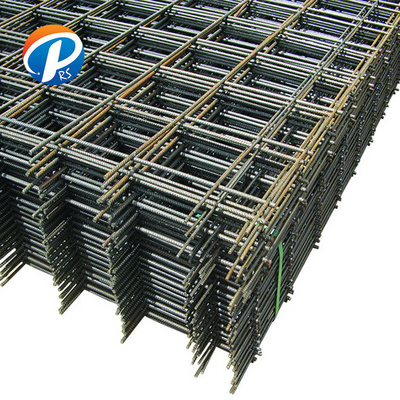

Performance of reinforcement bar and mesh made by the Company allow it to be widely applied both in civil and industrial construction, as well as in strengthening bridges and road fences. Plastic reinforcement tends to mainly replace steel rebar, which accounts for unique properties of the former, namely, first of all, its corrosion resistance, high tensile strength, light weight, and durability. Composite reinforcement is widely used in concrete industrial and civil buildings, since applying composite rebar provides for significant savings in construction, and most importantly greatly increases the quality of construction works. Use of composite rebar greatly increases lifespan of structures, as well as their overhaul period, due to high corrosion resistance, high strength, especially tensile strength, durability, low density and thermal conductivity. One should also bear in mind that Composite rebar is environmentally friendly. Besides, it is much cheaper and more affordable than steel rebar.

Wide experience and innivation approach in FRP production allowed the Company to design and develop a range of machinery for FRP product manufacturing. Our production lines combine all our best practices

the field of

FRP production, excellent quality of the final product and low cos of manufacture.

Composite Group Chelyabinsk is proud of its individual approach to each customer, which makes it possible to choose an optimum schedule, payment methods and a delivery option.