NaN / 0

High frequency metal iron copper Gold melting furnace for sale

Get Latest Price

US$ 1900

≥1 Boxes

US$ 1800

≥3 Boxes

Quick Details

Place of Origin:

Jiangxi, China

Brand Name:

Oasis

Voltage:

220V/380V

Dimension(L*W*H):

Depands

Product Details

High frequency metal iron copper Gold melting furnace for sale

Products Description

Product instroction

Gold melting Furnace is Frequency conversion electromagnetic induction heating or induction heating,melting,The maximum furnace temperature up to 1500-2000 degrees.it is can use gold,Platinum, silver, copper, iron, stainless steel, aluminum alloy, aluminum

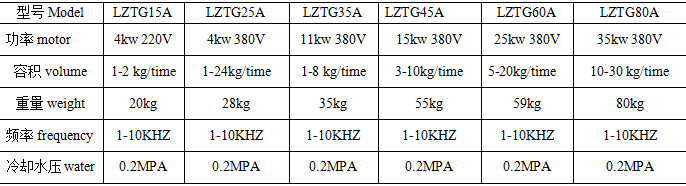

Technical specifications

products show

customer visiting us & Oasis in Exhibition

Related products

Packaging Details:Simple or as customer required

- Delivery Time :Shipped in 7-15 days after payment

Our company

Our distinctive prodcts include shaking table, Jig, Spriral separator, Gold concentrator, Ball mill, Jaw crusher, flotation, magnetic separator,electrostatic separator, vibrating screen, gold pan, feeder, classifier, ore washing machine and lab equipment ect. Our machines are popular in separating GOLD, copper, manganes, chrome, tungsten, tin, nickel, iron, titanium, lead, zinc, tantalum and some non-ferrous metals like quart, zircon, barite,ect.

our service

1.Starting by running the mineral beneficiation experiment. To provide our clients with the best solution accordingly;

2.Besides supply the flowchart design & equipment, we also provide the infrastructure design; Electrical & pipeline system design, etc. To help our clients complete the design of the whole plant;

Q: What Information should customers give to us in order to let we provide you with efficient & suitable quotation and assistance.

A

:

1. What type is the mining? Is it rock stone? or it is sand?

2. If rock stone,What is the general particle size(mm) of the raw ore?

3. What is the handling capacity(tons per hour) you plan to work with?

4.What is the elements of the raw ore? How much percent % of each minerals?

Hot Searches