NaN / 0

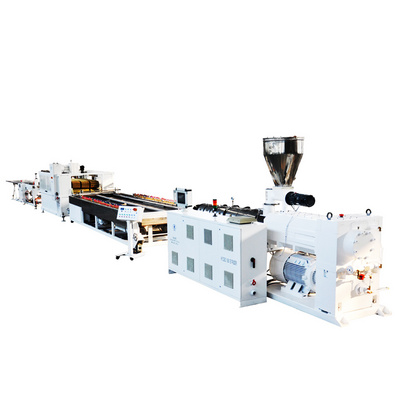

Kitech PVC WPC Wood Plastic Composite Door Window Making Machine Price

Get Latest Price

US$ 50000

≥1 Sets

US$ 45000

≥2 Sets

Quick Details

Screw Design:

Double-screw

Screw L/D Ratio:

Other

Screw diameter (mm):

Other

Screw Speed (rpm):

30 rpm

Product Details

Products Description

>>

For production of soft PVC profile, rigid PVC profile, soft-hard co-extrusion profile,foam profile extrusion, multi layer co-extrusion etc.

>>

Process Flow:

Screw Loader →cone / parallel Twin Screw Extruder/Single screw extruder → Co-extrusion machine → Mould → Calibration Table → Haul-off & Cutter →Tripping Table → Final Product Inspecting & Packing

Details Images

Conical twin screw extruder

• World famous brand electrical component such as Siemens,Schneider, ABB etc;

• High torque gearbox with adopts NSK/SKF bearing;

• Siemens/WEG original motor achieved global after service;

• Bimetallic screw and barrel;

• Intelligent PLC controlling system with human-friendly interface.

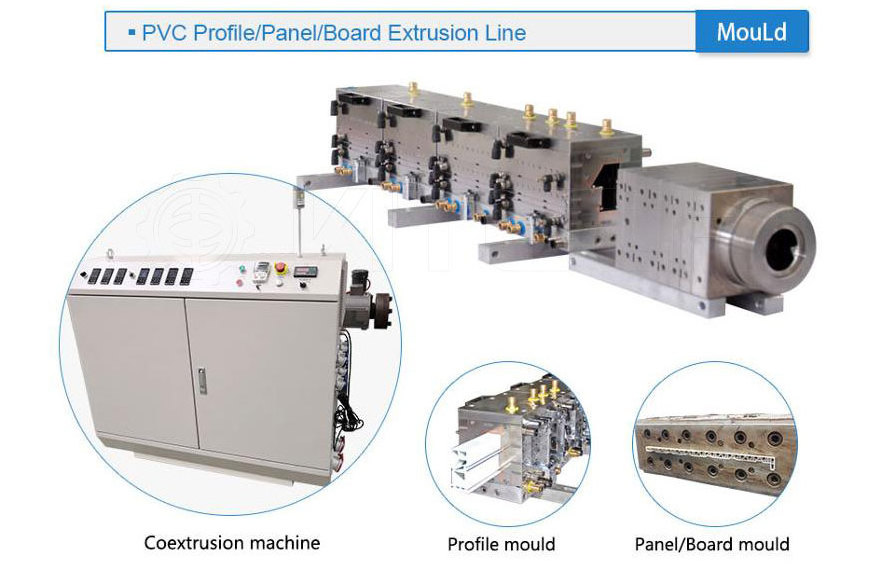

Die head

• 3Cr13/3Cr17 material;

•Complete set include extrusion die head, calibrator and cooling tank;

• Apply to soft PVC, rigid PVC, soft-hard co-extrusion profile, foamed profile, multi-layers co-extrusion etc.

Calibration table

• Include full set of vacuum and water pump;

• Length from 4m-11.5m;

• Independent operation panel for easy operation.

Haul off&Cutter

• Upper and lower caterpillar is driven separately and speed control by frequency inverter;

• Fast change type pads for easy operation;

• Install plate is adopts aluminum material;

• Compacting driving by pneumatic;

• Tracking cutter or lifting saw cutter with adopts double station dust collection system;

• Synchronous driving by air cylinder or servo motor control.

Stacker

• Stainless steel304 as touching material;

• Discharge driving by air cylinder.

Product Paramenters

|

Max. profile width(mm)

|

Extruder model

|

Designed capacity(kg/h)

|

Extruder motor power(kw)

|

|

180

|

ACE 51/105 or 55/110

|

80-120/120-150

|

18.5/22

|

|

240

|

ACE65/132

|

175-250

|

37

|

|

300

|

ACE65/132

|

175-250

|

37

|

|

400

|

ACE 65/132 or 80/156

|

175-250/250-350

|

37/55

|

|

600

|

ACE65/132 or 80/156

|

175-250/250-350

|

37/55

|

|

800

|

ACE80/156

|

280-350

|

55

|

|

Technical Parameter of Main extruder

|

|

|

|

|

|

|

|

|||||||

|

Model

|

Power

(kw)

|

Screw Diameter (mm)

|

Screw Qty.

|

Screw rotation speed(rpm)

|

Designed Output (kg/h)

|

Center Height (mm)

|

Dimension(L*W*H)

(mm)

|

|||||||

|

ACE-45/90

|

15

|

Φ45/90

|

2

|

34.7

|

70

|

1050

|

3360x1290x2127

|

|||||||

|

ACE-51/105

|

18.5

|

Φ51/105

|

2

|

34.7

|

100

|

1050

|

3360x1290x2127

|

|||||||

|

ACE-55/110

|

22

|

Φ55/110

|

2

|

34.7

|

150

|

1050

|

3620x1050x2157

|

|||||||

|

ACE-65/132

|

37

|

Φ65/132

|

2

|

34.7

|

300

|

1050

|

3715x1520x2450

|

|||||||

|

ACE-80/156

|

55

|

Φ80/156

|

2

|

34.7

|

400

|

1050

|

4750x1550x2460

|

|||||||

|

ACE-92/188

|

110

|

Φ92/188

|

2

|

34.7

|

750

|

1250

|

6725x1550x2814

|

|||||||

Why Choose Us

Customer Photos

Hot Searches