NaN / 0

Design Railway Track Crane Railway Steel Rail For Mining Use Standard Crane Track Stainless Steel Rail

Get Latest Price

US$ 500

≥1 Tons

US$ 450

≥20 Tons

US$ 300

≥50 Tons

Quick Details

Standard:

DIN

Grade:

Q235

Type:

Heavy Rail

Tolerance:

±10%

Product Details

Installation Instructions

Introduction Of

Design Railway Track Crane Railway Steel Rail For Mining Use Standard Crane Track Stainless Steel Rail

Steel rail is an important component used in railway systems, which is the track on which trains travel. Steel rails are usually made of high-quality steel and have characteristics such as high strength, wear resistance, and corrosion resistance.

The main function of the steel rail is to carry the weight of the train while providing a stable track for the train to travel. It can disperse the weight of the train, reduce ground pressure, and ensure safe and smooth operation of the train.

zmwm19

Steel rails are usually composed of multiple rail sections, each connected by bolts. The length of the track section is generally about 12 meters, and can be spliced and extended according to the needs of the railway line.

Steel rails require frequent maintenance and repair during use to ensure their normal operation and safety. Common maintenance tasks include track grinding, track replacement, track fastening, etc.

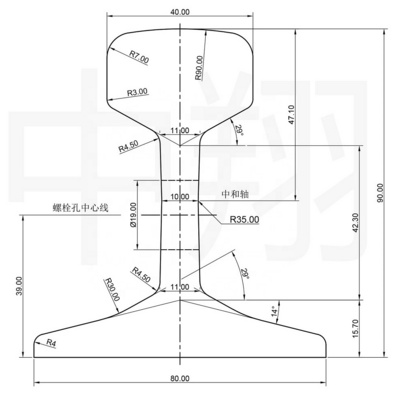

Product Paramenters

Product Paramenters Of

Design Railway Track Crane Railway Steel Rail For Mining Use Standard Crane Track Stainless Steel Rail

|

THE LIST OF YYGT

|

|

|

|

|

|

|

||||||

|

Name of Commodity

|

Specificaton

|

Materials (Steel Grade)

|

Standard of Products

|

Theory Weight (kgs/M)

|

Length of Dimension (M)

|

Packed In Bundle With Iron Wire (pcs/bundle)

|

||||||

|

Light Rail

|

4kgs/m

|

Q235

|

Q/YG001-2014

|

4kgs/m

|

6,8

|

75

|

||||||

|

|

8kgs/m

|

Q235

|

Q/YG001-2014

|

8.42kgs/m

|

|

55

|

||||||

|

|

12kgs/m

|

Q235

|

GB11264-2012

|

12.2kgs/m

|

|

36

|

||||||

|

|

15kgs/m

|

Q235/55Q

|

GB11264-2012

|

15.2kgs/m

|

6,8,9,10

|

28

|

||||||

|

|

18kgs/m

|

Q235/55Q

|

Q/YG001-2014

|

18.06kgs/m

|

|

21

|

||||||

|

|

22kgs/m

|

Q235/55Q

|

GB11264-2012

|

22.3kgs/m

|

|

21

|

||||||

|

|

24kgs/m

|

Q235/55Q

|

Q/YG001-2014

|

24.46kgs/m

|

|

21

|

||||||

|

|

30kgs/m

|

Q235/55Q

|

GB11264-2014

|

30.1kgs/m

|

|

15

|

||||||

|

Heavy Rail

|

38kgs/m

|

U71Mn

|

GB2585-2007

|

38.733kgs/M

|

12,12.5

|

10

|

||||||

|

|

43kg/m

|

U71Mn

|

GB2585-2007

|

44.653kgs/M

|

|

10

|

||||||

|

|

50kgs/m

|

U71Mn

|

GB2585-2007

|

51.514kgs/M

|

|

10

|

||||||

|

|

|

45/50Mn

|

Q/YYG002-2008

|

31/34/36/39/41kgs/M

|

12,12.5

|

10

|

||||||

|

Crane Rail

|

QU70

|

U71Mn

|

YB/T5055-93

|

52.8kgs/m

|

12

|

10

|

||||||

|

|

QU80

|

|

YB/T5055-93

|

63.69kgs/m

|

|

10

|

||||||

|

|

QU100

|

|

YB/T5055-93

|

88.96kgs/m

|

|

5

|

||||||

|

|

QU120

|

|

YB/T5055-93

|

118.1kgs/m

|

|

5

|

||||||

Details lmages

Product Image Of

Design Railway Track Crane Railway Steel Rail For Mining Use Standard Crane Track Stainless Steel Rail

Why Choose Us

FAQ

1. You are a manufacturing factory or trading company?

China Coal Group is a manufacturing factory base of mines support equipment, transport equipment, lifting equipment, spray equipment, drilling equipment, ventilation equipment and other products.

2. Where is your factory located?

Currently we have one factories in China. One located in Jining, Shandong Province, China . You are warmly welcome to visit us at any time.

3. What are your main products?

We mainly produce mining machinery and railway equipment. We can provide you with any machinery you need!

4. How long is the production leadtime?

Generally it is 15-20 days for goods in stock. In the case of out of stock or large orders, it will take 20-30 days. QTY of the orders will be taken into consideration.

5. What payment terms do you accept?

Payment terms: TT in advance (30% of deposit before production and 70% balance before shipment), bank transfer, Paypal, L/C etc.

6. How do your quality control systems operate?

We have professional designer team, and employ experienced engineers to strictly guarantee the production. Meanwhile our factory owns ISO9001 and is CE and SGS certified.

Hot Searches