NaN / 0

plastic bushing nylon bush sleeve PA6 pipe ABS tube bushing Plastic pad column straight through Isolation column

Get Latest Price

US$ 0.1

≥10 Pieces

Quick Details

Applicable Industries:

Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Construction works

Type:

sleeve

Material:

MC nylon PA6

Place of Origin:

Shandong, China

Product Details

Contact us for more Dimensions

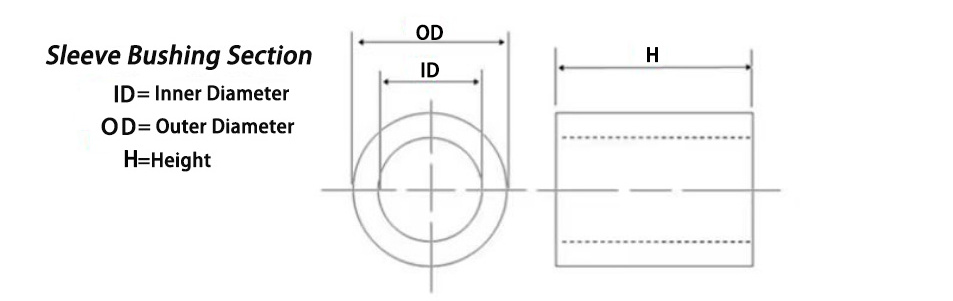

SECTION

(Tolerance:

±0.01mm)

PRODUCT DIMENSIONS

Please find more dimensions in the chart below

|

ID*OD*H

|

ID*OD*H

|

ID*OD*H

|

ID*OD*H

|

ID*OD*H

|

|

ID=3 OD=7 H=2

|

ID=3 OD=7 H=3

|

ID=3 OD=7 H=4

|

ID=3 OD=7 H=5

|

ID=3 OD=7 H=6

|

|

ID=3 OD=7 H=7

|

ID=3 OD=7 H=8

|

ID=3 OD=7 H=9

|

ID=3 OD=7 H=10

|

ID=3 OD=7 H=11

|

|

ID=3 OD=7 H=12

|

ID=3 OD=7 H=13

|

ID=3 OD=7 H=14

|

ID=3 OD=7 H=15

|

ID=4 OD=7 H=2

|

|

ID=4 OD=7 H=3

|

ID=4 OD=7 H=4

|

ID=4 OD=7 H=5

|

ID=4 OD=7 H=6

|

ID=4 OD=7 H=7

|

|

ID=4 OD=7 H=8

|

ID=4 OD=7 H=9

|

ID=4 OD=7 H=10

|

ID=4 OD=7 H=11

|

ID=4 OD=7 H=12

|

|

ID=4 OD=7 H=13

|

ID=4 OD=7 H=14

|

ID=4 OD=7 H=15

|

ID=5 OD=7 H=2

|

ID=5 OD=7 H=3

|

|

ID=5 OD=7 H=4

|

ID=5 OD=7 H=5

|

ID=5 OD=7 H=6

|

ID=5 OD=7 H=7

|

ID=5 OD=7 H=8

|

|

ID=5 OD=7 H=9

|

ID=5 OD=7 H=10

|

ID=5 OD=7 H=12

|

ID=5 OD=7 H=15

|

ID=6 OD=9 H=3

|

|

ID=6 OD=9 H=4

|

ID=6 OD=9 H=5

|

ID=6 OD=9 H=6

|

ID=6 OD=9 H=8

|

ID=6 OD=9 H=10

|

|

ID=6 OD=9 H=12

|

ID=6 OD=9 H=13

|

ID=6 OD=9 H=15

|

ID=6.2 OD=11 H=3

|

ID=6.2 OD=11 H=4

|

|

ID=6.2 OD=11 H=5

|

ID=6.4 OD=12 H=34.5

|

ID=8.2 OD=14.9 H=27.2

|

ID=8 OD=11 H=40

|

ID=8 OD=30 H=3

|

|

ID=8 OD=34 H=16.1

|

ID=8.1 OD=17.8 H=4.25

|

ID=8.16 OD=10 H=9.8

|

ID=8.23 OD=16.6 H=8

|

ID=9 OD=4 H=4

|

|

ID=10 OD=6.2 H=4

|

ID=10 OD=30 H=3

|

ID=10.7 OD=20 H=35

|

ID=12 OD=9.6 H=6

|

ID=12 OD=14 H=10

|

|

ID=12 OD=30 H=3

|

ID=12.5 OD=6.5 H=9.5

|

ID=13 OD=6.2 H=17.5

|

ID=13 OD=6.2 H=20

|

ID=15 OD=6.2 H=5

|

|

ID=15 OD=6.2 H=7

|

ID=16.1 OD=19.4 H=11

|

ID=20 OD=30 H=3

|

ID=25 OD=9 H=6

|

|

PRODUCT OVERVIEW

IN-STOCK Nylon Sleeve Bushing

PRODUCT DISCRIPTION

|

Product Name

|

In-Stock

Nylon

S

leeve Bushing

|

|

Product Method

|

CNC Producing

|

|

Dimension

|

ID3mm--ID20mm

|

|

Material

|

MC Nylon/POM/PA66/Delrin/Plastic

|

|

Color

|

White/ Optional

|

|

Packing

|

Ziplock bag& Carton with woven bag for small quantity; Wooden Box for large quantity

|

|

Delivery

|

2-3 days for in-stock PTFE bushinig, 7-10 days for custom made bushing (according to quantity).

|

|

Shipping

|

air, sea and express delivery

|

|

Application

|

Domestic electrical, aotumotive, engineering machiniery, industry

|

|

Drawing Format

|

2D/3D STEP/STP/STE, etc

|

|

Quotation

|

According to drawing or samples

|

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

Item

|

Data

|

|

1

|

Relative Density

|

1.15 g/cm

|

Resistance to Temperature

|

120°C

|

|

2

|

Rockwell Hardness

|

M114

|

Continuous Heat Resistance

|

100°C

|

|

3

|

Bibulous Rate

|

3.0%-4.2%

|

The Tensile Strength

|

74MPa

|

|

4

|

Dielectric Strength

|

18 (KV/mm)

|

The Bending Strength

|

96-100MPa

|

|

5

|

The Coefficient of Friction

|

0.085-0.15

|

Coefficient of Thermal Conductivity

|

0.233W/(m.k)

|

OUR PRODUCTION AND EQUIPMETS

PRODUCT PACKAGING

Ziplock Bag

Carton & Woven Bag

Wooden Box

FAQ

Q:What is your product range?

A:

Our factory professionally manufactures engineering plastic parts such as nylon pulleys, nylon/POM/ PTFE/ ACETAL bushing, sleeves, washers, bars and other plastic products. We have plenty of in-stock product and also can customize according to customers’ requirements.

Q:

Can you provide OEM service?

A:

Yes, we work on OEM orders.Which means size, material, color, design, packaging solution, etc., will depend on your requests.

nylon bush M4/M5M6M7M8M9M10M12M15MM16M18M20M25 custom made pom sleeve bushing

Q:

How can I get a sample?

A:

Small size of blank samples are free, you only need to pay for the freight charge.

Customized size samples should be charged.

Customized size samples should be charged.

Q:

What is your delivery time?

A:

It depends on product complexity and order qty. Normally, it takes us 2-3 days for an small quantity.

Q: What is your payment terms?

A:

30% T/T in advance, 70% balance before shipment. Other terms negotiable.

Q:

How about transportation and package?

A:

Safe package and prompt delivery, reliable and cheap freight company.

CONTACT US

Lisa Guo

Tel: +86 155 5260 5649

Email: lisa@nylonpartsmfg.com

WhatsApp: +8615552605649

Wechat: a15552605649

Skype: 15552605649

DEZHOU CHIXIANG MACHINERY PARTS CO., LTD

No. 222 Chuangye South Road, Qizhong Village, Xinhua Street Office, Decheng Dist., Dezhou, Shandong, China

Email: lisa@nylonpartsmfg.com

WhatsApp: +8615552605649

Wechat: a15552605649

Skype: 15552605649

DEZHOU CHIXIANG MACHINERY PARTS CO., LTD

No. 222 Chuangye South Road, Qizhong Village, Xinhua Street Office, Decheng Dist., Dezhou, Shandong, China

Hot Searches