NaN / 0

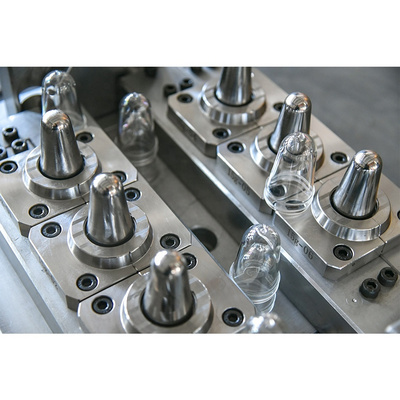

Mould PET Preform mold / Mini Plastic Injection Molding Machine for Bottle made in china

Get Latest Price

US$ 15000

≥1 Sets

Quick Details

Distance between Tie Bars(Width)(mm):

360mm

Distance between Tie Bars(Height)(mm):

360mm

Mold Height(mm):

150 - 380 mm

Ejector Stroke(mm):

80 mm

Product Details

Product Overviews

Product Overviews

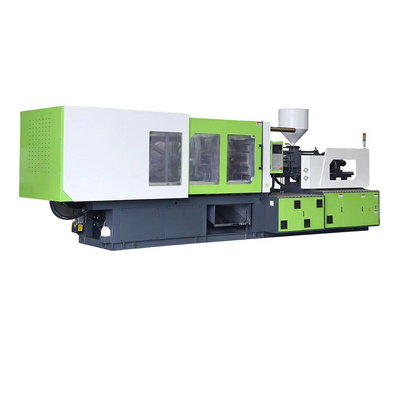

Small mini

Energy saving Servo Plastic Injection Molding Machine Price

Injection molding machines are also known as injection molding machines or injection machines. It is the main molding equipment for thermoplastic or thermosetting plastics using plastic molding dies to make plastic products of various shapes. Divided into vertical, horizontal, all-electric. The injection molding machine heats the plastic and applies a high pressure to the molten plastic to eject it to fill the mold cavity.

Machine details

|

SPECIFICATION ITEM |

KBD900 |

|||

|

Injection unit |

Unit |

A |

B |

C |

|

SCREW DIA |

mm |

32 |

35 |

38 |

|

SHOT VOLUME (THEORETICAL) |

cm3 |

128 |

153 |

181 |

|

INJECTION WEIGHT(PS) |

g |

118 |

14 |

166 |

|

INJECTION PRESSURE |

Mpa |

203 |

169 |

144 |

|

SCREW SPEED |

rpm |

0-220 |

||

|

CLAMPING UNIT |

||||

|

CLAMPING FORCE |

KN |

900 |

||

|

TOGGLE STROKE |

mm |

320 |

||

|

SPACE BETWEEN TIE BARS |

mm |

360*360 |

||

|

MAX.MOLD HEIGHT |

mm |

380 |

||

|

Min.MOLD HEIGHT |

mm |

150 |

||

|

EJECTOR STROKE |

mm |

80 |

||

|

EJECTOR TONNAGE |

KN |

31 |

||

|

OTHERS |

|

|||

|

PUMP MOTER POWER |

Kw |

11 |

||

|

HEATING POWER |

Kw |

7 |

||

|

MACHINE DIMENSION(L*W*H) |

m |

4.05*1.25*1.8 |

||

|

MACHINE WEIGHT |

T |

2.9 |

||

High quality international accessories

Product Description

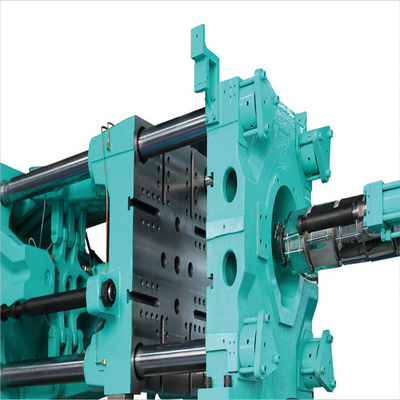

Clamping unit

- Strong rigidity of the template and Stable operation

- The optimized front joint connecting rod adopts integral casting, which has good rigidity and stable operation.

- The railings and guides are made of aluminum/copper sleeves or self-lubricating guide sleeves, which have a special wear resistance and low friction coefficient. it dramatically increases the life service of the draw bar.

-

The template adopts a structure in which a T-shaped groove and a mounting screw coexist. Reasonable T-slot layout not only facilitates the installation of the mold, but also increases the strength of the template.

-

The Tie rods of each model are tested by the most professional inspection mechanism to ensure that the deformation of the tie rods is within a reasonable range when the machine is in operation.

Injection Unit

-

Accurate Injection and Stable operation

-

Injection, pressure holding pressure closed-loop control, back pressure precision control

-

The barrel screw has a long life and is easy to replace

-

Personalized design, including nozzle shied and central lubrication,it reduced operation intensity and that ’ s convenient for daily maintenance while guaranteeing safety

Hydraulic Unit

-

Fast response and stable output

-

The hydraulic system adopts imported famous brand hydraulic components, and adopts the oil circuit combining the plug-in and the slide valve to effectively improve the response speed of the system.

-

High-efficient and energy-saving servo control system.

-

Responsive to fast and stable hydraulic control components.

-

Precision and stable hydraulic power unit.

Precision control unit

-

Responds quickly and stably

-

It adopts international famous brand controller, fully enclosed electrical control box, and reasonable electrical components.

-

TFT LCD color display.

A high-performance controller specially for injection molding machine .

High-precision displacement sensor as soon as possible.

Energy-saving drives and servo motors.

-

Online update program, data export, easy operation and multi-language support are available using USB. More than 10 languages.

KEBIDA SERVO INJECTION MOLDING MACHINE ENERGY SAVING-KEBIDA PLASTIC MACHINERY

The KBD servo-driven energy-saving precision injection molding machine is equipped with a high-performance servo motor power control system. The power output of the motor varies with the load drive, and there is no waste of excess energy. During the holding phase, the servo motor reduces the speed and the energy consumption is extremely low. During the cooling phase, the motor does not work and the power consumption is 0. The servo energy-saving system is equipped with a rotary encoder and a pressure sensor to feedback the flow and pressure at all times. This changes the speed and torque of the servo motor, so that the flow pressure is adjusted accordingly to ensure a higher repeatability of the product.

-

System power consumption comparison And Structural schematic

-

20%-80% Energy saving.

-

Quick Response

Sensitive Servo Motor ,The response time only 0.05 Second .

-

Quite&Low Noise.

The machine runs with low noise, and will be mach quieter in a low speed.

-

Oil temperature rise slowly .

Servo motor proportionally deliver hydraulic oil base on our needs ,it ’ s can prevent unnecessary heat being generated. Even in some case does not require cooling.

-

KBD excellent characteristics inheritance.

Outstanding machine stability being safety and dependability, strong mechanical parts ,complete functional human-oriented operation system and long service life .

Hot Searches