NaN / 0

2.4856 N06625 Nickel Alloy Inconel 601 625 718 Tube / Pipe Used for Indus

Get Latest Price

US$ 15

≥1 Kilograms

Quick Details

Resistance (μΩ.m):

Stable

Powder Or Not:

Not Powder

Ultimate Strength (≥ MPa):

730

Elongation (≥ %):

30

Product Details

Products Description

Inconel 625

INCONEL® nickel-chromium alloy 625 (UNS N06625/W.Nr. 2.4856) is used for its high strength,excellent fabricability (including joining), and outstanding corrosion resistance. Service temperatures range from cryogenic to 1800°F (982°C). Composition is shown in Table 1.

Strength of INCONEL alloy 625 is derived from the stiffening effect of molybdenum and niobium on its nickel-chromium matrix; thus precipitationhardening treatments are not required. This combination of elements also is responsible for superior resistance to a wide range of corrosive environments of unusual severity as well as to high-temperature effects such as oxidation and carburization。

Strength of INCONEL alloy 625 is derived from the stiffening effect of molybdenum and niobium on its nickel-chromium matrix; thus precipitationhardening treatments are not required. This combination of elements also is responsible for superior resistance to a wide range of corrosive environments of unusual severity as well as to high-temperature effects such as oxidation and carburization。

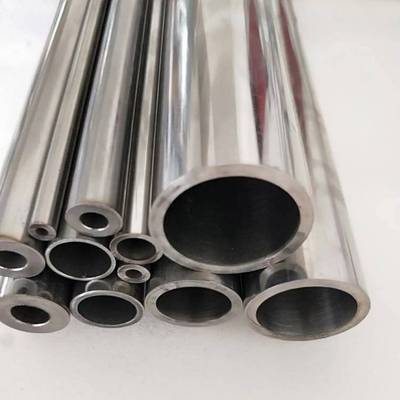

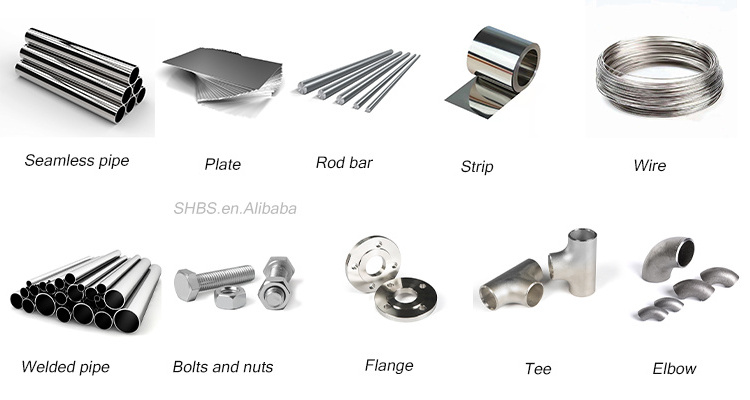

Product display

Click here to send inquiry→

Performance introduction

C

hemical composition

|

Nickel…………………………………………….…………58.0 min. Chromium………………………………………..…………20.0-23.0

|

|

|

|

|

||||

|

Iron………………………………………………..………….5.0 max. Molybdenum……………………………….……...…………8.0-10.0

|

|

|

|

|

||||

|

Niobium (plus Tantalum)………………………..3.15-4.15 Carbon……………………………………………..……….0.10 max.

|

|

|

|

|

||||

|

Manganese………………………………………....….0.50 max. Silicon……………………………….…………...…………0.50 max.

|

|

|

|

|

||||

|

Phosphorus……………………………………….…….0.015 max. Sulfur…………………………………..……….…..……..0.015 max.

|

|

|

|

|

||||

|

Aluminum…………………………………………………..0.40 max. Titanium……………………………….……………………0.40 max.

|

|

|

|

|

||||

|

Cobalta ……………………………………………………….1.0 max.

|

|

|

|

|

||||

Physical Constants

|

Density, lb/cu in

|

0.305

|

|

|

|

||||

|

gram/cc

|

8.44

|

|

|

|

||||

|

Melting Range, °F

|

2350-2460°C…………………………………………1290-1350

|

|

|

|

||||

|

Specific Heata , Btu/lb°F (J/kg°C)

|

|

|

|

|

||||

|

0°F (-18°C)………………………………0.096 (402)

|

|

|

|

|

||||

|

70°F (21°)………………………………..0.098(410)

|

|

|

|

|

||||

|

200°F (93°C)……………..………………0.102 (427)

|

|

|

|

|

||||

|

400°F (204°C)……………………………0.109 (456)

|

|

|

|

|

||||

|

600°F (316°C)…………………...……….0.115 (481)

|

|

|

|

|

||||

|

800°F(427°C)…………………...……….0.122 (511)

|

|

|

|

|

||||

|

1000°F (538°C)…………..………………0.128 (536)

|

|

|

|

|

||||

|

1200°F (649°C)…………………………..0.135 (565)

|

|

|

|

|

||||

|

1400°F(760°C)…………………………..0.141 (590)

|

|

|

|

|

||||

|

1600°F (871°C)……………..……………0.148 (620)

|

|

|

|

|

||||

|

1800°F (982°C)…………………….…….0.154 (645)

|

|

|

|

|

||||

|

2000°F(1093°C)…………………..……..0.160 (670)

|

|

|

|

|

||||

|

Permeability at 200 Oersted (15.9 kA/m)…………….………..1.0006

|

|

|

|

|

||||

|

Curie Temperature,°F…………………………...……………...<-320 °C……………………….…………………..-196

|

|

|

|

|

||||

Nominal Room-Temperature Mechanical-Property Ranges

FAQ

Q: Are you a trading company or a manufacturer?

A: We are a direct factory with production lines and workers. Everything is flexible and

there is no need to worry about intermediariesOr additional fees for traders.

Q: Which countries do you export to?

A: Our products are mainly exported to Australia, Canada, Britain, the United

States, Germany, Thailand, South Korea and so on.

Q: Do you provide samples? Is it free or extra?

A: Yes, we can provide samples , but we don't pay the freight.

Q: What is your minimum order quantity?

A: In fact, there is no minimum order quantity for our products. But usually we

recommend quantities based on acceptable prices.

Q: How about the delivery time?

A: It is order based, usually within 15-30 days after receiving your advance payment.