NaN / 0

Direct-to-Wall CMYKW 3D UV Vertical Graffiti Printer Multicolor Inkjet Painting Machine with 220V Voltage Reliable Printhead

Get Latest Price

US$ 4852

≥1 Sets

US$ 4672

≥2 Sets

US$ 4492

≥6 Sets

Quick Details

Print Dimension:

2500mm

Condition:

New

Color & Page:

Multicolor

Ink Type:

waterbase ink

Product Details

3D WALL PRINTER MACHINE

Product Description

3d wall printer advantage

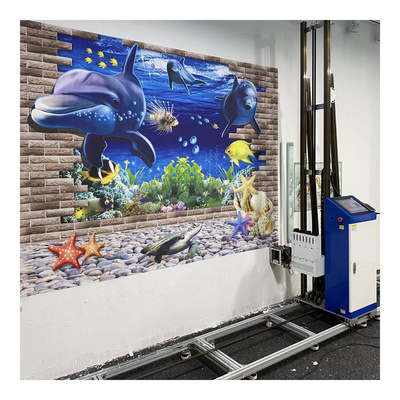

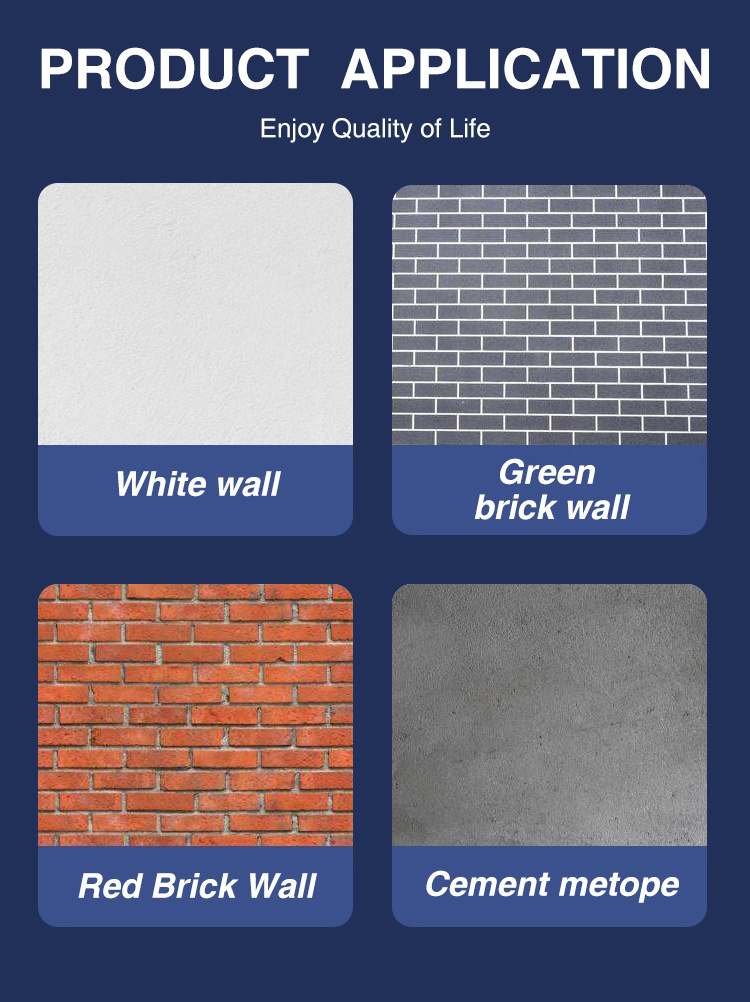

1.Can Be applied to a variety of materials wall, for example White Wall, LATEX PAINT WALL, Shell powder wall, ceramic tile, glass KT board

2. Supports printing color ink and white ink at the same time

3. The number and type of printing nozzles are optional, different printing speed and printing accuracy

4. Print height can be customized, unlimited length

One set of ink, 5 colors, Red Yellow Blue Black White; each color 500ml;

one set of uv ink costs 95usd, which can print 150 square meters. so the average of Ink consumption 16.7ml/sqm. The cost is

0.63usd/sqm.

one set of water based ink costs 75usd, which can print 150 square meters. so the cost is 0.5usd/sqm

one set of uv ink costs 95usd, which can print 150 square meters. so the average of Ink consumption 16.7ml/sqm. The cost is 0.63usd/sqm.

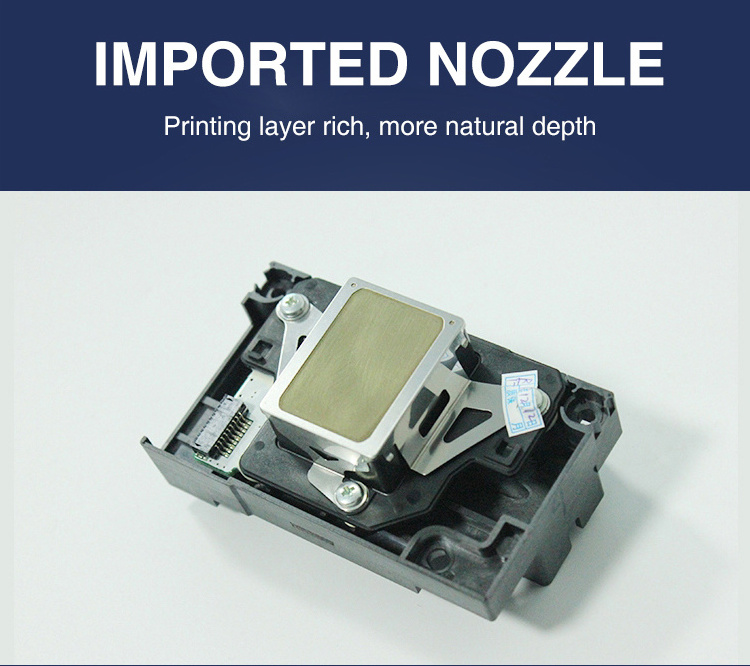

3d wall printer imported nozzle.

Three different nozzles are available.

DX10 lifespan is about 20,000 square meters printing

DX7 lifespan is about 30,000 square meters printing.

4720 lifespan is about 40,000 square

DX7 lifespan is about 30,000 square meters printing.

4720 lifespan is about 40,000 square

3d wall printer for alloccasions

if you have any question, please

contact us

Epson TX800 printing head

One printing head can print 15000 square meters

High resolution printing

360x720dpi/720x1080dpi/720x1440dpi/1080x1440dpi/1440x2880dpi

8 core CPU,8GB RAM

High speed processor with 8-core CPU,

Computer machines are integrated, no need to be equipped with laptop computers.

High quality UV ink

Equipped with ink curing lights for uv model, no restrictions on any material quality of fine picture, good color, waterproof protection of the sun protection more lasting, no need for waterproof treatment.

|

KD260 parameters

|

|

|

|

|

||||

|

Printing software

|

|

Genuine professional printing software

|

|

|

||||

|

Using ink

|

|

Special environmental protection organic water-based ink (waterproof, anti stripping)

|

|

|

||||

|

Control mode

|

|

Wired / wireless printing

|

|

|

||||

|

Transportation

|

|

(foldable)

|

|

|

||||

|

Power consumption

|

|

No load 20W, maximum 250w

|

|

|

||||

|

Surface tracking

|

|

Hyperbolic banner sensor, up and down bidirectional induction

|

|

|

||||

|

Ink supply system

|

|

Positive pressure system single color single supply, 4-color ink bin one body

|

|

|

||||

|

Print size

|

|

2.5Height × width, more than 2 meters can be seamless splicing

|

|

|

||||

|

Construction noise

|

|

Standby < 20db, drawing < 70db

|

|

|

||||

|

Supporting pictures

|

|

Photos taken by mobile phone / camera and Internet

|

|

|

||||

|

Power requirements

|

|

Household electricity: 220 VAC or 380 VAC

|

|

|

||||

|

Applicable media

|

|

White wall, ceramic tile, glass, metal, acrylic, paper, etc

|

|

|

||||

|

Format of national film

|

|

include PSD.CDR, JPG, JPEG, PNG, BMP, tiff, EPS, AI and PDF

|

|

|

||||

|

Color drawing technology

|

|

Micro piezoelectricity spray technology, variable ink drop, high tolerance error emerging technology, automatic memory recovery

technology for construction interruption |

|

|

||||

|

Print Resolution

|

|

360x720dpi/720x1080dpi/720x1440dpi/1080x1440dpi/1440x2880dpi

|

|

|

||||

|

Operating environment

|

|

-20 ° c-50 ° C (- 4f-122f), 10% - 70% relative humidity, non condensing state

|

|

|

||||

|

Storage environment

|

|

-21c-5o ° C (- 22f-140 ° f), 10% - 70% relative humidity, non condensing state

|

|

|

||||

|

operating platform

|

|

Windows xP/7/8/9/10

|

|

|

||||

|

Certification qualification

|

|

Green environmental protection certification, national standard test qualified (GB 18582-2001, gbt9756-2001), CE certification

|

|

|

||||

|

Printing speed

|

PASS

|

|

M2 / h (M '/ h)

|

|

||||

|

Fast mode

|

A

|

|

15

|

|

||||

|

Production mode

|

B

|

|

10

|

|

||||

|

Quality model

|

C

|

|

7

|

|

||||

|

HD mode

|

D

|

|

5

|

|

||||

|

External dimension

|

Machine scale mm); length 700* width 300* height 2600

|

|

Package size (mm): length 800*width 460*height 2700

|

|

||||

|

Machine weight

|

Machine 60kg (fuselage 30kg + 3 guide rails 30kg)

|

|

Gross weight 115KG in wooden case

|

|

||||

|

Key components

|

|

|

|

|

||||

|

Nozzle specification

|

Epson 10 generation high precision printing nozzle 2

|

Electric machinery

|

3 Imported intelligent servo motor + reducer

|

|

||||

|

main board

|

8Core high speed CPU, 4GB memory, high speed USB 1o

|

Wall detection

|

2Nano distance detectors

|

|

||||

|

level

|

Imported precision level

|

Power failure alarm

|

Real time power failure alarm system

|

|

||||

|

UPS power supply

|

Super uninterruptible power supply with 3 hours of power failure

|

Laser positioningLaser positioning

|

Precise infrared laser positioning system

|

|

||||

|

Shaft guide

|

High strength precision railway track, 4 sections, 1.5m, 6m in total

|

Shaft guide

|

Imported linear drive module

|

|

||||

|

Ink supply technology

|

Positive pressure system ink supply, need to draw ink

|

Gift Gallery

|

Free 2T Library

|

|

||||

|

Language

|

Chinese / English (other languages can be customized)

|

|

|

|

||||

|

Note: the above parameters are design parameters. In case of any difference, the actual use efficiency of the equipment shall prevail.

|

|

|

|

|

||||

Packing & Delivery

We use express UPS, DHL, EMS, FedEx, and the package will reach your hand in 6-12 working days.

FAQ

1)

How many printheads does the Wall printer have?

Printhead number is optional; it can be equipped with 2 or 3 print heads

2)

Can it print white color/ does it have CMYK + W?

Yes the wall printer can print white color.

3)

What accesories will come with the printer?

The printer comes with 4 rails(each 1.5m long), one set of ink and nozzle cleaner.

4)

What type of ink does it support?

Wated based in or UV ink

5)

Which shipping way will have less cost?

Shipping by sea will have less cost, but with ink together, the cost will be a bit higher than normal.

6)

Are there other product appearances that can be choosen?

Yes, there are two options; one is in blue; the other is in yellow.

7)

Is the printer equipped with Touch screen?

Nope, the printer is equipped with computer along with mouse and keyboard.

8)

What is the Print head brand?

Epson DX10

9)

What Language does the software support?

it supports English and Chinese only

it supports English and Chinese only

10)

How do we clean the printed wall?

The printed pictures cannot be washed away; it needs to paint the wall again to cover it.

The printed pictures cannot be washed away; it needs to paint the wall again to cover it.

11)

Do you offer free printing samples?

Yes, we can print some samples according to customer's requirements.

Yes, we can print some samples according to customer's requirements.

12)

What's your delivery time?

We will arrange the delivery within 3~7 working days after receiving the deposit.

We will arrange the delivery within 3~7 working days after receiving the deposit.

13)

What payment method are supported?

Payment method is T/T or LC, PayPal, Western Union, Credit Card, etc.

14)

If I have some technical problem, how can you help us to solve it?

Detailed description, photos or video will help our technician analyze the problem and give solution accordingly.

Detailed description, photos or video will help our technician analyze the problem and give solution accordingly.

15)

Once there is something need to replace, what can I do?

We supply all the spare parts for the printer. If any part is broken, we will fix it or send you new parts after users send back the broken ones. We suggest that users order spare parts package for long time maintenance and fast replacement.

We supply all the spare parts for the printer. If any part is broken, we will fix it or send you new parts after users send back the broken ones. We suggest that users order spare parts package for long time maintenance and fast replacement.

16)

Can we send our technician to your factory for training?

Yes, you are warmly welcome to visit us for free training.

Our Company

Shenyang Faith Technology Co., Ltd. is a high-tech enterprise, which integrates independent research and development, production,sales and service.

It specializes in providing industrial coding technology and traceable system solutions. The company was founded in 2010 with a 30-person team and a 500㎡ production workshop. After more than 10 years of unremitting efforts, by early 2020, it has developed into an excellent team of 300 people and a 2500㎡ production workshop.

The company's products mainly include

laser marking machines, CIJ printers, TIJ printers, and conveyor belts. The products are exported to Spain, the United States,Brazil, Argentina, Chile, Saudi Arabia, the UAE, Egypt, Ecuador and other 126 countries, serving more than 200,000 customers.

The

company's philosophy is focus on coding, treats quality as the base and service-oriented principles. Shenyang Faith Technology's vision is to become the most professional, caring and trustworthy enterprise in the printing industry.

Online After-sales Service 24 Hours

No matter you seek help at any place, any time, we can respond quickly excellent technical consultant, provide the best solution online.

Two Years Warranty

During the warranty period we provide professional, considerate and timely after-sales service.

Our Factory

We have our own factory, can provide the goods for you at the first time, if your goods have any problem, we can solve for you immediately.

Customer Feedback

Our products have been well received by customers, I hope you can rest assured that purchase.

If you have any question,please

contact us

Hot Searches