NaN / 0

Hydraulic aluminum profile corner crimping machine for windows doors

Get Latest Price

US$ 16000

≥1 Sets

Quick Details

Brand Name:

Better

Voltage:

220/380/415v

Weight:

3000 kg

Production Capacity:

100 per min

Product Details

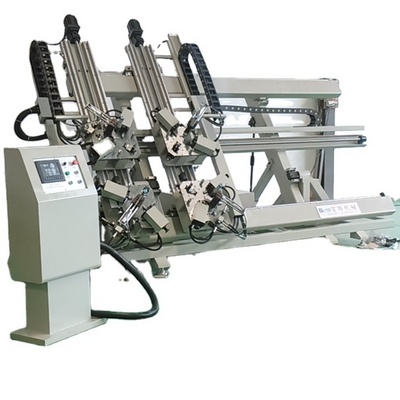

Hydraulic aluminum profile corner crimping machine for windows doors, ZJ-CNC-100x1800x3000

workshop layout

Product Description

The machine is used for corner punching and riveting combination of aluminum profiles at 90 degree . Complete the connection of four corners in one operation with high production eff i ciency . The frame is specially jointed by steel with high quality and special process.The CNC system imported from Lenze, Germany, with high quality ensures the speed and accuracy. The moment control function of the service system can auto press the four corners , ensuring the processing effect.The corner combining blade can be adjusted according to the requirement of different profile.One time corner crimping can control the seam and plane, make the quality foresight.The control system service system make the connect no-seam and improve the control accuracy.

|

Voltage |

As request |

|

Rating power |

4 Kw |

|

Rating oil pressure |

15 Mpa |

|

Air consumption pressure |

0.5-0.8 Mpa |

|

Air consumption |

0.45 L once |

|

Capability of oil box |

60L |

|

Corner crimping journey |

0-50mm |

|

Max frame dimension |

1800 mm * 3000 mm |

|

Min frame dimension |

480 mm *48 0 mm |

|

Profile width |

95mm |

|

E rror of finished windows |

≤1mm |

|

Connection seam error |

≤0.15mm |

|

Contour dimension ( L * W * H ) |

4700 * 2000 * 2600mm |

|

Weight ( about ) |

2500Kg |

alu-machine

Hot Searches