NaN / 0

Factory Price SBR 1502 Styrene Butadiene Rubber 1502 Sinopec 1502

Get Latest Price

US$ 165

≥5 Pieces

Quick Details

Place of Origin:

Thailand

Model Number:

Virgin SBR 1502

Product name:

Carboxylic Styrene Butadiene Latex

Appearance:

Milky White Liquid

Product Details

Styrene Butadiene Rubber / SBR 1502

SBR 1502

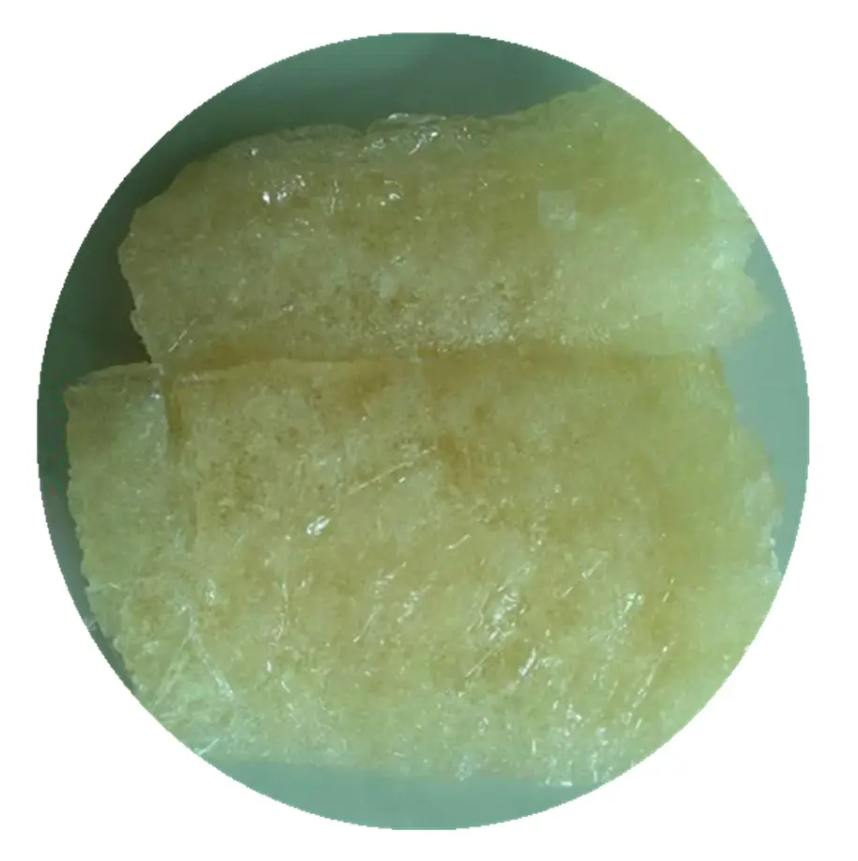

is one of the most widely used synthetic rubber.

Low temperature emulsion polymerized technique. Its wear resistance,aging resistance,ozone resistance,water-proofing,air tightness and homogenous are much better.

Low temperature emulsion polymerized technique. Its wear resistance,aging resistance,ozone resistance,water-proofing,air tightness and homogenous are much better.

Specification:

End Use:

End uses include white sidewall tires, footwear, light and dark coloured mechanical goods and miscellaneous items where excellent physical properties and minimum discoloration and staining are required.

Packing: 35 kg / bag

End uses include white sidewall tires, footwear, light and dark coloured mechanical goods and miscellaneous items where excellent physical properties and minimum discoloration and staining are required.

Packing: 35 kg / bag

Hot Searches