NaN / 0

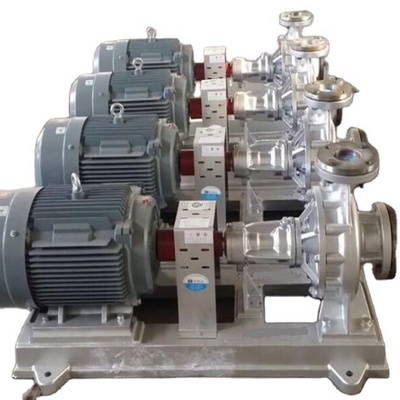

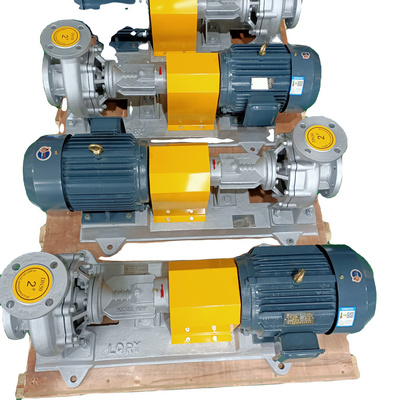

oil transfer pump mechanical seal high temperature hot oil circulation pump

Get Latest Price

US$ 285

≥1 Sets

Quick Details

Application:

Wastewater Transport and Flood Control, wastewater treatment

Pressure:

High pressure

Voltage:

380V, 380V

Brand Name:

AOBL

Product Details

Product Description

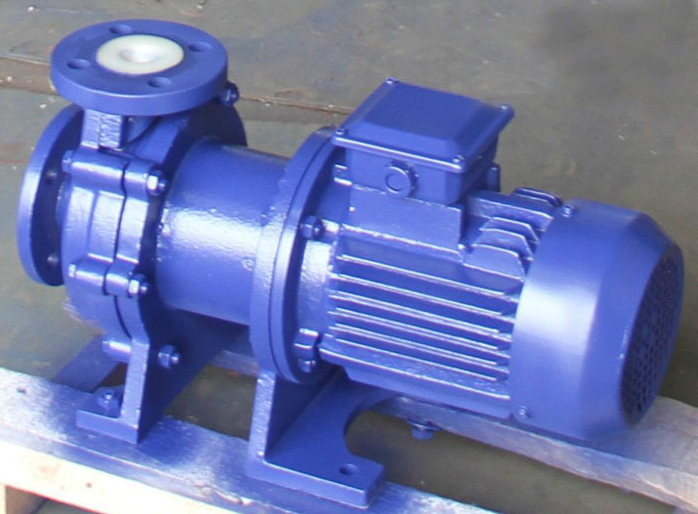

Feature:

1. Excellent acid and alkali resistance: according to acidic and alkaline of medium to choose FRPP or PVDF material

2. Magnetic synchronous drive, no contact and friction, low power dissipation, high efficiency, with vibration damping effect.

3. Sealless & no leakage

4. Easy installation: standard inner body, delicate structure

5. High durability: heat dissipation structure inside

6. Wide-used: M series (0.5kw-5kw) model, for the various industrial processes, such as PCB processes, chemical industry, filter cycle, etching, electroplating, surface treatment sewage treatment, excellent performance and durability

2. Magnetic synchronous drive, no contact and friction, low power dissipation, high efficiency, with vibration damping effect.

3. Sealless & no leakage

4. Easy installation: standard inner body, delicate structure

5. High durability: heat dissipation structure inside

6. Wide-used: M series (0.5kw-5kw) model, for the various industrial processes, such as PCB processes, chemical industry, filter cycle, etching, electroplating, surface treatment sewage treatment, excellent performance and durability

boiler electric motor 380v FRPP material plastic acid proof chemical pump

When applied to heat-exchange, install a pressure gauge at the outlet to ensure no blockage in the pipeline.

A strainer should be installed at the inlet to revent solids from being sucked in.

Install valves at the inlet and the outlet for easy maintenance.

Strainer mesh should be dia. 5~7mm and total mesh area is 5 times the pipe area or more.

1. Different chemical solutions mixed together will cause reaction and even heat to damage the pump. Don't pump different chemical solutions with the same pump.

2. Chemicals may cause serious injury. Keep away from dangerous area.

3. Before operating, please check the discharge and suction line and valvesrst. Make sure valves are all in correct position, then start. During operation, check discharge usually.

4. Incorrect operation, for example, valves closed, incompatible material and dry running may cause dangerous. Especially dry running, it will cause heat as well as vapor, even some chemical decomposes hydrogen and explode.

5. Start the pump and check the discharge from the outlet. If it is too low, unplug the pump immediately, and check the pipeline if there is any block..

6. The pump can be equipped with explosive-proof and pressure-proof motor.

Product Reference

Certifications

|

|

|

|

|

|

Hot Searches