NaN / 0

Drum type grain, soybean residue, chicken manure sand feed dryer equipment

Get Latest Price

US$ 3545

≥1 Sets

Quick Details

Weight (KG):

200

Marketing Type:

Multi functional use

Type:

dryer

Use:

Wet material dehydration and drying use

Product Details

Applicable scope of dryer:

1. Chemical, mining, metallurgical and other industries, such as ore, sand, river sand, slag, coal slurry, metal powder, clay, diatomaceous earth, kaolin. Small automatic electric controlled temperature fish scale dryer Stainless steel scale powder dryer Scale electric heating drying equipment

2. Agriculture, feed and fertilizer industries, such as straw, forage, leaves, fish meal, corn paste, starch residue, distiller's grains, medicine residue, fruit residue, soy sauce residue, bagasse, peat, organic compound fertilizer, sludge, aquatic product waste, food factory waste, slaughterhouse waste, Organic fertilizer (chicken manure, cow manure, quail manure, etc.), inorganic fertilizer, ammonium phosphate fertilizer and ammonium sulfate.

3. Powder and granular materials: such as various crystals, lightweight calcium carbonate, activated clay, magnetic powder, graphite, inorganic mud, clay, lime slurry, ore mud, phosphorus slag, aluminum factory red mud.

4. Construction industry: Dehydration and drying of building materials such as river sand and mud.

5. Wood processing industry: sawdust, sawdust, bamboo charcoal, activated carbon, etc.

6. Miscellaneous grain processing industry: corn, sorghum, rice, glutinous rice, barley, wheat, tartary buckwheat, mung beans, soybeans, red beans, barley, flour, etc.

|

Dimension

|

3500*1300*1500

|

|

Inner cylinder size

|

1000*2000

|

|

Heating method

|

Electric heating, diesel heating, particle heating

|

|

scope of application

|

Rapeseed, peanuts, soybeans, chili peppers, river sand, organic fertilizers, etc

|

Product advantages:

Fast efficiency, high output, good assistant for drying raw materials

1. The equipment has a simple structure, small size, convenient operation, and does not need to be equipped with other equipment, making it easy to transport and move.

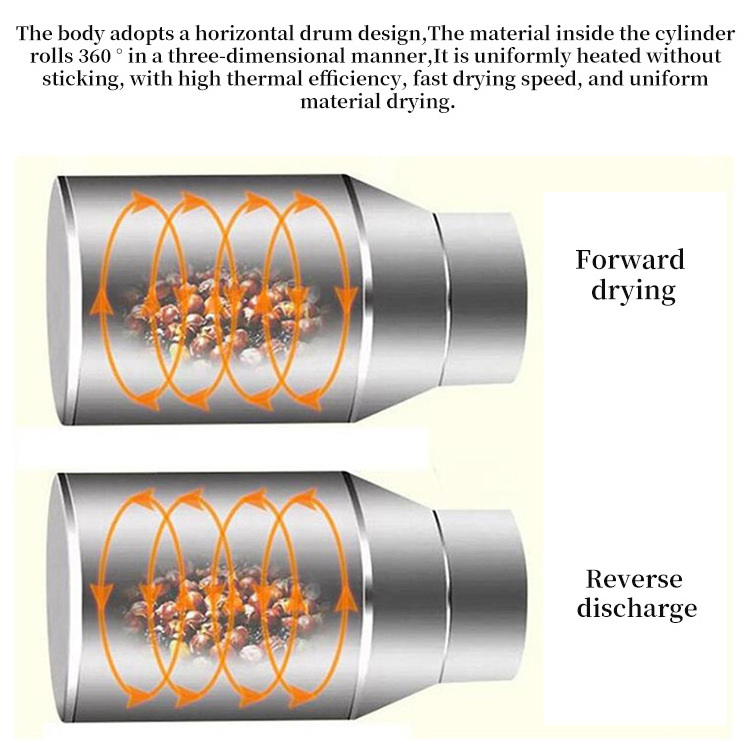

2. Using hot air as the drying medium and adopting the rotary convection drying process, the material is evenly heated and has good quality after drying

3. The dryer uses coal, rice husk, or straw as fuel, which is converted into clean hot air through combustion and heat exchange, with minimal impact on the dried crops.

4. Low investment, low usage cost, automatic control of work process, automatic shutdown, simple and labor-saving operation, meeting the needs of small and medium-sized farms and farmers

5. Equipped with automatic online temperature measurement and humidity measurement device, with high automation and good drying uniformity.

6. Easy to clean, no mixing, especially suitable for dry grain crops

Zhengzhou Fude Machinery Equipment Co., Ltd., established in 2015, is a factory that integrates mechanical research and development, manufacturing, and sales. Its main products include wood crushers, dryers, and organic fertilizer equipment

Service tenet: Integrity management, ensuring quality control, and satisfying both parties

FAQ

FAQ

Q:Are you a trading company or a manufacturing factory?

A:We are a factory。

Q:What is your delivery time?

A:If the goods are in stock, it usually takes 7-10 days。

If the goods are out of stock, it will take 15 to 30 days, calculated by quantity。

Q:What is your payment method?

A:30% of the total price should be paid in T/T as the down payment; 70%

of the remaining payment should be paid in T/T before delivery。

Q:Do you provide technical guidance?

A:Yes, we will provide you with professional advice on the

selection of models and the operation of equipment。