NaN / 0

shoe insole cardboard paper board making converting machinery with paperboard dryer

Get Latest Price

US$ 54000

≥1 Sets

US$ 53600

≥2 Sets

Quick Details

Production Capacity:

20 set/month

Product Type:

Paperboard Machine

Place of Origin:

Henan, China

Brand Name:

Shunfu

Product Details

shoe insole cardboard paper board making converting machinery with paperboard dryer

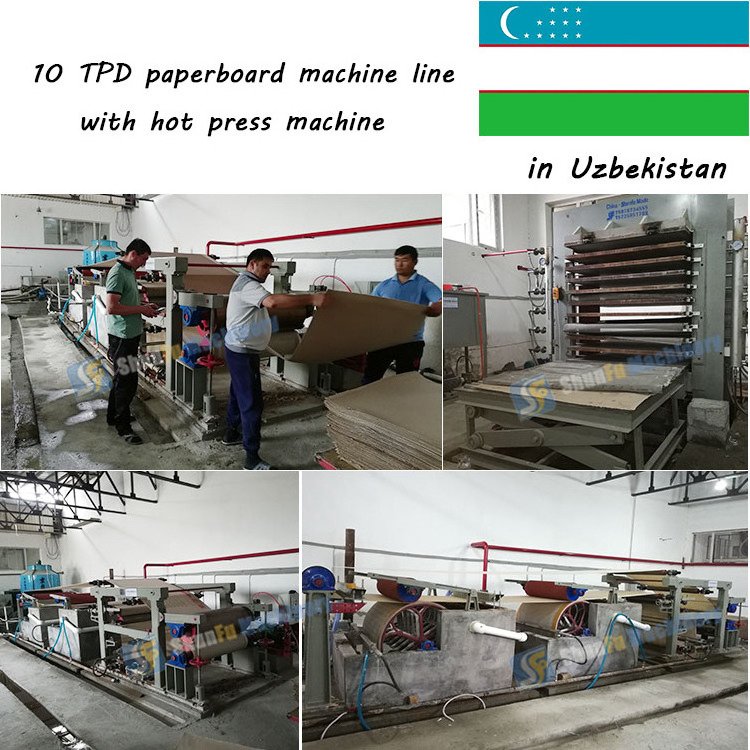

Success cases

Product Profile

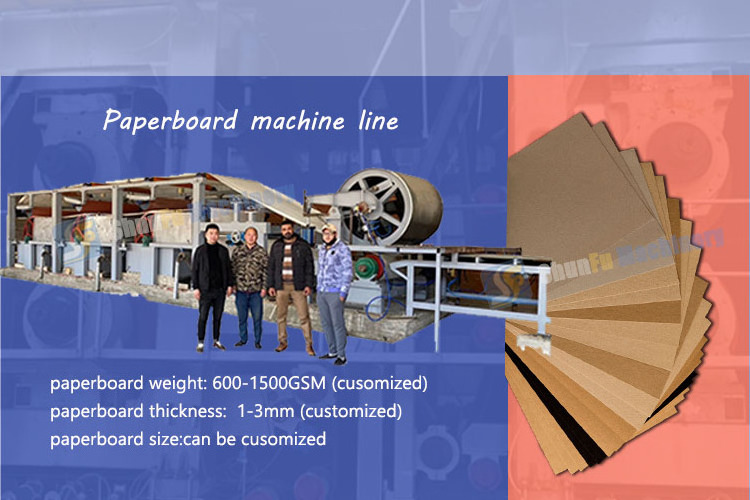

♦P aperboard Machine Introduction♦

paperboard making production line machine successfully solve the problem of the comprehensive development and utilization of the paper mill sludge(waste paper pulp), can transform waste products into useful product , to solve the environmental protection is not only input into the contradiction, and achieved good economic and environmental benefits.

♦Paperboard Machine Configuration♦

|

Configuration Name |

Details |

|

Product Name |

shoe insole cardboard paper board making converting machinery with paperboard dryer |

|

Finished Paper Product |

Paperboard,Cardboard etc. |

|

Raw material |

Waste Paper;Waste Paper Pulp;Paper Sludge |

|

Thick of paper |

Can debugging |

|

Specifications |

1300mm×1000mm ( Can debugging ) |

|

Speed |

30~50m/min |

|

1set capacity |

1-10t/d (If you need to add the capacity, you need to buy many sets) |

|

Consistency of pulp |

0.8~1% |

|

Host power |

5.5kw |

|

Appearance size |

7000mm×2700mm×2000mm |

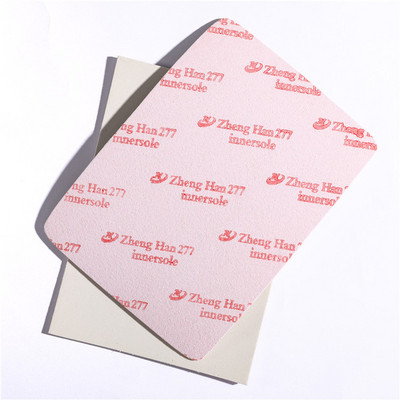

♦Final Paperboard &Application

Product Details

♦Pulping Part♦

The following equipments make the raw materails into paperpulp,it is the first step to produce paperboad.

♦Raw Materials♦

The biggest advantage of paperboard machine is that can use the paper mill sludge( waste pulp )do as the raw materials to

produce final paperboard product.To help paper mill achieve waste recycling and achieve economic income.

♦Paperboard Machine Host♦

This part is the main part for paperboard machine line, it from paperboard forming to big paperboard.The forming part can be divided into cylinder mould type and fourdrinier two types ,more bigger capacity can be used for fourdrinier type.

♦Paperboard Machine Drying♦

Paperboard making machine can be divided into 2 types up to the drying way: 1.Sun drying 2.Hot press machine to dry.

Paperboard making machine can be divided into 2 types upe to the automatic type:1.Semi-automatic type 2.Full-automatic.

♦Calender Machine ♦

Calender machine are used in sun drying paperboard machine,it can Improve gloss, smoothness and tightness of paperboard.

♦ Paperboard Cutting Machine ♦

Paperboard cutting machine cut the big size paperboard into fixed size paperboard sheet,it is optional.

Company Introdution

♦Factory Profile ♦

Qinyang Shunfu Paper Making Machinery Co.,Ltd located in Qinyang city henan province,China,is a leading professional paper machine manufacturer in China with best quality and perfect service&good reputation for 30+ years.Since 1988 ,shunfu company built,in 2020 year,Huatuo company built,till now,we have 2 factories and workhouse.Doing paper making machine,we are always on the way.

♦Company Main Business♦

1. Various pulp making machine;

2. Various paper making machine;

3. Various paper processing machine;

5. Technical service, such as installation, update old paper machine.

♦Exhibition & Customer visiting♦

For our factory,we will go to paper machine professional exhibition 1 time once year.

We not only do mainland business,but also do the abroad business.Help our customers get considerable income Our paper machine are sold throughout the country over 20 provinces and areas, and exported to Vietnam, Burma,Uzbekistan,Russia ,Kyrgyzstan, Nigeria, Ukraine, Botswana, Libya, Algeria, El Salvador , Lebanon, Moldova, Bolivia, Egypt, South Africa and other countries.The trust and praise by the user.

♦ Technical Support ♦

Packaging & Shipping

♦PACKING&Loading ♦

(1).Paperboard making production line machines cardboard will be packaged according to their shapes, weight, transport distance and transport modes .

(2). In normal condition:

01-The dryer is packed with wood chips for protecting its surface

02- The large diameter roll is packed with wood chips.

03- The steel rolls are packed with plastic film and straw ropes.

04- Electric control cabinet is packed with three-ply board box.

05- Some parts are nude cargo.

FAQ&Buy Tips

♦ Buy Tips ♦

In order to know well about your requirement for paperboard machine and avoid misunderstanding, please check the following information of paperboard machine and feedback us your idea, we can make accurate quotation complete according to your requirement:

|

Q1: Whats raw material you want to use? |

A: Waste (pulp)paper,waste carton,Sludge etc. |

|

Q2: How many ton per day you want to produce paperboard? |

A: In normal:3-10 ton,bigger capacity can be customzied. |

|

Q3: What size you want to make the paperboard? |

A: Customized |

|

Q4: How many grammage for paper weight(gsm)? |

A: Customized |

Hot Searches