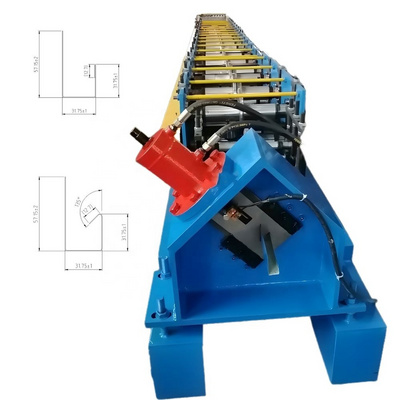

Coil inner Diameter: ¢460-520mm

Max out diameter of the coil: ¢1500mm

Max Coil Width: 500mm

|

|

Items

|

Specifications

|

|

Material of coil

|

Material Thickness

|

0.4 mm-1.2 mm galvanized steel

|

|

De-coiler

|

Weight

|

3 ton manual

|

|

Forming system

|

Rolling Speed

|

10-12m/min

|

|

|

Roller Stations

|

About 9 stations forming

|

|

|

Roller Material

|

Cr40 Steel with quenching

|

|

|

Shaft Material

|

45# Steel Diameter 60mm shaft

|

|

|

Maim Motor Power

|

5.5 kw

|

|

|

Hydraulic cutting Power

|

4 kw

|

|

Cutting

system |

Material Of Cutting

|

CR12 with quench treatment

|

|

|

Hardness

|

HRC58-62

|

|

|

Tolerance

|

+-1.5mm

|

|

Electrical control system

|

Electric Source

|

220V, 60HZ,3 phase

|

|

|

Control System

|

PLC Control

|

|

|

Weight

|

About 3 tons

|

|

|

Way Of Drive

|

1 inch single chain

|

|

|

Size of machine

|

Length 5500mm* Width 600mm* Height 800m

|

|

3 ton passive de-coiler

|

1 set

|

|

Main roll forming machine

|

1 set

|

|

Cutting device

|

2 sets

|

|

PLC Control box

|

1 unit

|

|

Hydraulic station

|

1 unit

|

|

Out table

|

1 unit

|

|

Safety cover

|

1 unit

|