NaN / 0

Beige Marble Vinyl Floor Tile Adhesive Stone Glue For Bonding Ceramic Tile

Get Latest Price

US$ 10

≥10 Tons

Quick Details

CAS No.:

3824500000

Other Names:

Tile adhesive

MF:

Mixture

EINECS No.:

3824500000

Product Details

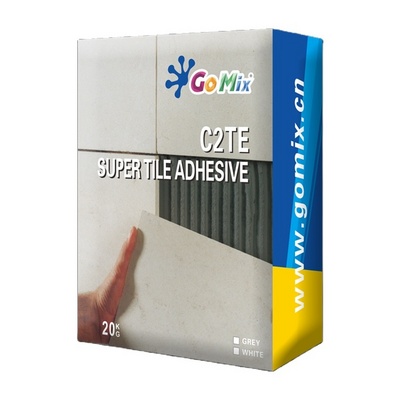

Beige Marble Vinyl Floor Tile Adhesive Stone Glue For Bonding Ceramic Tile

Introduction:

Tile Adhesive is a premium grade, thick or thin bed, fast setting, polymer modified, flexible, powdered cement based adhesive, specifically formulated to bond tiles onto a variety of substrates. Classified as BS EN 12004 Type C1.

Feature:

1. Has strong cohesion force. Reduce the common phenomenon of tiles detaching and peeling when pasted by Portland cement.

2. Be premixed and produced, the product is stable, water and used, to protect the construction environment.

3. Has strong water retention, no need to dip tiles and wet walls, thin construction, easy operation, to reduce material consumption and building load.

4. Has good flexibility to resist effectively the destruction of various stresses.

5. Has special formula to avoid completely the common phenomenon of tiles cracking, detaching and peeling by Portland cement.

6. It is no-toxic, no-radiation, no smell and environmental.

7. Has special formula to prevent the flow with too much southbound crash, easier construction.

Application:

It is used to fix porcelain tiles, marbles, natural granites, natural stones, travertine,pool tiles and pieces, and non-slip tiles of middle sized (up to 60x60cm size for the wall and any size for the floor).

suitable to bond the following types of tile:

A):Ceramic, extruded and earthenware tiles

B): Low absorption ceramic tiles, which have poor adhesion to traditional tile

adhesives

C):Concrete and mortar

D): Bricks

E):Plaster (with primer)

F):Plasterboard, fibre cement

G):Existing tiled substrates

Coverage:

1.Use 3*3mm notched trowel,approx.1.5-1.8kg/m2

2.Use 6*6mm notched trowel,approx.2.8-3.0kg/m2

(The above dosage are recommened for the even substrate)

Technical Date:

|

Surface drying time(Hr) |

≤5 |

|

|

Cohesive strength |

standard state (Mpa) |

≥0.6 |

|

Freeze-thaw cycle (Mpa) |

≥0.4 |

|

|

Alkali resistance (48hr) |

No change |

|

|

Water resistance (96hr) |

No change |

|

|

Using level (kg/ m²) |

1-1.5 |

|

|

color |

White and g rey |

|

Picture:

Shipping Picture:

Hot Searches