NaN / 0

Submersible sewage pump customizable submersible slurry pump centrifugal pump

Get Latest Price

US$ 155

≥1 Sets

Quick Details

Application:

Wastewater Transport and Flood Control, wastewater treatment, Other

Pressure:

Other

Voltage:

380V, 380V

Warranty:

1 years

Product Details

1、 WQ sewage pump product overview

WQ sewage pump is a new generation pump product which is developed on the basis of introducing foreign technology and combining with the characteristics of domestic water pump. It has the characteristics of energy saving, winding prevention, no blockage, automatic installation and automatic control. It has good effect in discharging solid particles and long fiber waste.

WQ submersible sewage pump adopts new mechanical seal, which can effectively transport solid and long fiber. Compared with the traditional impeller, the impeller of the pump adopts the form of single or double channel, which is similar to a bend with the same section size, and has excellent over-current. It is equipped with a reasonable worm chamber, which makes the impeller have high efficiency and no vibration during operation.

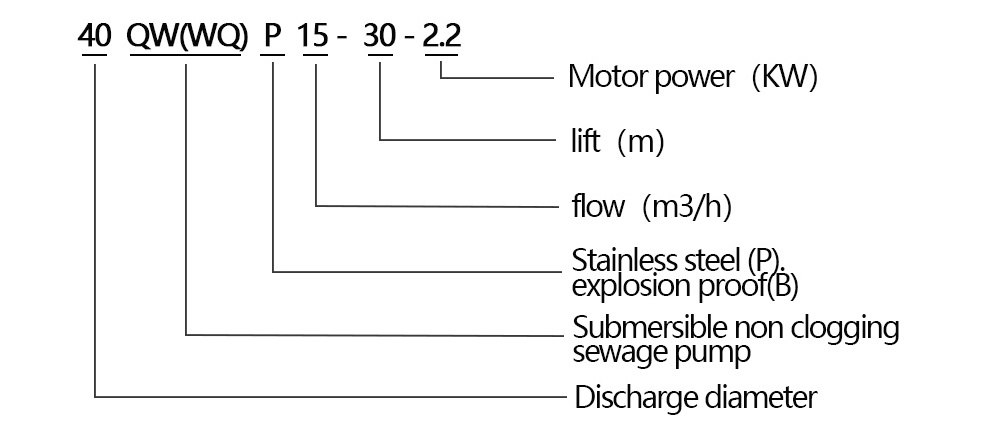

2、 WQ sewage pump model and significance

3、 Features of WQ sewage pump

1. Using single or double impeller structure, it can effectively pass through 5 times of the diameter of the pump fiber and 50% of the diameter of the solid particles.

2. The mechanical seal is made of new hard and corrosion-resistant titanium tungsten material, which can make the pump run continuously for more than 8000 hours.

3. It has the advantages of compact structure, small volume, low noise, remarkable energy-saving effect, convenient maintenance, no need to build pump house, and can work under water and reduce project cost.

4. The sealing oil chamber of the pump is equipped with a high-precision anti-interference water leakage detection sensor, and a thermal element is embedded in the stator winding to automatically protect the water pump motor.

5. The automatic control cabinet can be equipped according to the needs of users, which can automatically protect the leakage, leakage, overload and over temperature of the pump, so as to improve the reliability of the product.

6. The float switch can automatically control the start and stop of the pump according to the change of the required liquid level. It is very convenient to use without special personnel.

7. WQ submersible sewage pump can be equipped with double guide rail automatic coupling installation system according to the needs of users. It brings more convenience for installation and maintenance, and people do not have to enter the sewage pit for this purpose.

8. It can be used in full head without overload.

9. There are two different installation methods, fixed automatic coupling installation system, mobile free installation.

4、 Main uses of WQ sewage pump

WQ submersible sewage pump is suitable for conveying sewage and dirt with particles in chemical industry, petroleum industry, pharmaceutical industry, mining industry, paper industry, cement plant, steel plant, power plant, coal processing industry, urban sewage treatment plant drainage system, municipal engineering, construction site and other industries. It can also be used for pumping clean water and corrosive media.

|

Fault phenomenon

|

Causes

|

resolvent

|

|

|

4.stuck or worn |

1.Remove debris Adjust pump depth Check 2.the power supply voltage, power line 3.connector and starting switch Adjust the two connectors

4.at will, adjust the steering direction, remove the debris or replace the impeller |

|

Unit heating Stop and turn (protection start switch starts)

|

1.The supply voltage is too low

2.The power lead is too thin

3.It is used in large flow and low lift area

4.Seal damage, water ingress

|

1.Adjust the voltage

2. Replace the wire

3. Adjust to rated head for use

4.Adjust or replace the drying motor and seal

|

|

Excessive noise and vibration

|

1.Shaft bending

2. Bearing wear

3.Loose connecting bolt

|

1.Straightening shaft

2.Replace the bearing

3.Tighten the bolts

|

Other specific models please consult customer service

The operating conditions are water temperature ≤ 60 ℃ and pH value of liquid is 4-10.

① QW (WQ) submersible sewage pump adopts single blade or double blade impeller structure, which can effectively pass through 5 times of the diameter of the pump and solid particles with the diameter of about 50% of the pump diameter.

② The mechanical seal of QW (WQ) submersible sewage pump is made of new hard and corrosion-resistant tungsten carbide material. At the same time, the seal is improved to double end face seal, which can make the pump run continuously for more than 8000 hours in oil chamber for a long time.

③ QW (WQ) submersible sewage pump has the advantages of compact structure, small volume, low noise, remarkable energy-saving effect, convenient maintenance, no need to build a pump house, and can work in the water and reduce the project cost.

④ QW (WQ) submersible sewage pump seal oil chamber is equipped with high-precision anti-interference water leakage detection sensor, and the stator winding is embedded with thermal elements to protect the pump motor.

⑤ QW (WQ) submersible sewage pump can be equipped with automatic safety protection control cabinet according to the needs of users to protect the leakage, leakage, overload and over temperature of the pump, so as to improve the reliability of the product.

⑥ The float switch can automatically control the start and stop of the pump according to the change of the required liquid. It is convenient to use without special personnel.

⑦ According to the needs of users, it can be equipped with double guide rail automatic coupling installation system, which brings convenience for installation and maintenance, and people do not have to enter the sewage pit for this.

⑧ It can be used in full head range without overload.

⑨ There are two different installation methods: fixed automatic coupling installation system and mobile free installation.

Explore More Products

Hot Searches