NaN / 0

PVC Plastic Concrete Construction Formwork Suppliers

Get Latest Price

US$ 75

≥100 Square meters

US$ 70

≥500 Square meters

US$ 65

≥2000 Square meters

US$ 60

≥5000 Square meters

Quick Details

Warranty:

1 Year

After-sale Service:

Online technical support, Onsite Installation, Onsite Training

Project Solution Capability:

graphic design

Application:

Apartment

Product Details

Product Description

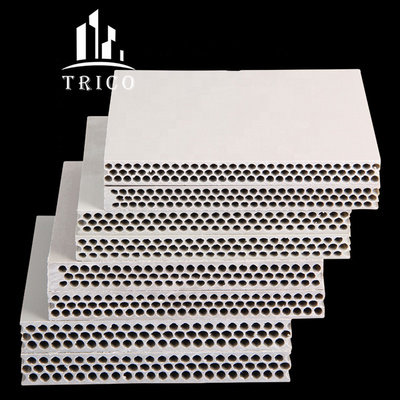

Specification

|

Product Name

|

High Quality Plastic formwork for Concrete

|

|

Materials

|

High Quality plastic materials

|

|

Types

|

Flat Formwork, Corner Formwork, Angel Corner Formwork etc

|

|

Shipping

|

Mainly by sea or railway shipping or your ideas

|

|

Application

|

Plastic Formwork is widely used in villas, commercial buildings, foundations, basement ect..

Especially for foam concrete, used together with plastic formwork TP60 across from many construction sites, they are born to match with each other. |

|

Advantages

|

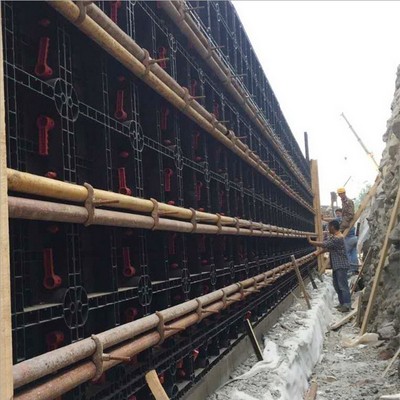

* Can build modular houses for shear wall, slab, column and beams with various sizes

* Up to 100 times usages under good maintenance * Unit cost per casting of material is much lower than regular formwork * Average weight 15kg per square meter only * It helps to save construction time a lot * No need to use form release agent, that is another saving * Concrete surface is smoother as the plastic formwork surface does not absorb the concrete water, that will save a lot of thick plastering work for surface leveling and smoothing * General labor can do the job which save the carpenter cost and manpower * Output is faster as no much saw cutting and nailing works involved * Site is tidier |

Plastic formwork is a system of modular formwork in plastic used to build two-way ribbed slabs in residential and commercial

buildings. The system is designed to decrease the weight of traditional full-concrete slabs. The dome-shaped forms create a matrix

of voids surrounded by orthogonal ribbing, producing a two-way configuration very suitable for large-spanning slabs.

buildings. The system is designed to decrease the weight of traditional full-concrete slabs. The dome-shaped forms create a matrix

of voids surrounded by orthogonal ribbing, producing a two-way configuration very suitable for large-spanning slabs.

Packing & Delivery

FAQ

FREQUENTLY ASK QUESTIONS:(If your questions are unlisted on below, pls Click here to let usknow.)

-Q-: Do I use this set of formwork to another project?

A: There are nearly 70% standard panels can be common use.

-Q-:What's your packing methods?

A: protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depend on clients special requirement.

-Q-:What's your payment terms?

A: T/T 30% in advance & T/T 70% upon sending the copy of Bill of Lading, L/ C 100%, or negotiate according to the order status

-Q-:Are you manufacturer or trader?

A: We are the munafacturer of aluminum formwork system and coveraged every scaffolding systems.

-Q-:If I don't have people know well about your forwmork system?

A: We will guide you how to settle them down if necessary