NaN / 0

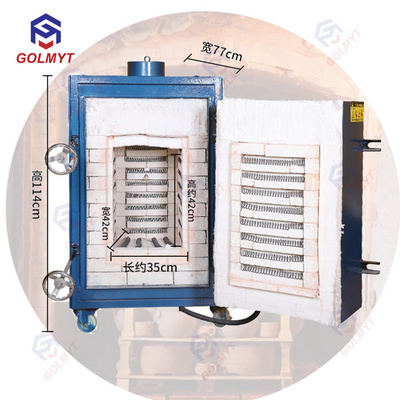

Ceramic fiber gas fired bogie hearth gas furnace

Get Latest Price

US$ 1000

≥1 Sets

Quick Details

Place of Origin:

China

Brand Name:

GOLMYT

Voltage:

Requirement

Dimension(L*W*H):

customizable

Product Details

High temperature chamber furnace for firing ceramics, earthenware, clay and porcelain

Product Description

Product details

|

Effective size |

custom mode |

|

Key Selling Points |

High Safety Level Technical Parameters |

|

custom mode Operating temperature range |

From room temperature to 200 ℃ |

|

Weight |

4T-110T |

|

Warranty |

12 Months |

Process descriptio

coal-fired hot air furnace use bituminous coal / soft coal as fuel. It has the features of safety, high-efficiency, energy efficient, environment friendly, small covering area and easy installation. At present, it is the first choice to replace the CWS hot air furnace.

consists of coal-fired machine, combustion chamber and air mixing chamber. The bituminous coal is lifted to the burning bucket (located at one side of the coal-fired machine) by the coaling machine. When get to a certain height, the coal is sent to the combustion chamber at a constant speed by the chain grate stoker. The flue gas (1000℃) generated by the burning coal is mixed with a certain amount of cold air. When get to about 650℃, the hot air enters into the spray tower to dry the material. The temperature of the hot air can be adjusted according to different technical requirements, and the fluctuation range of the continuous hot air temperature is ±5℃. The coal slag is discharged from the other side of the coal-fired machine to the slag discharging machine, and then sent out by the automatic scraper slag machine.

Details picture

Contact information

Hot Searches