NaN / 0

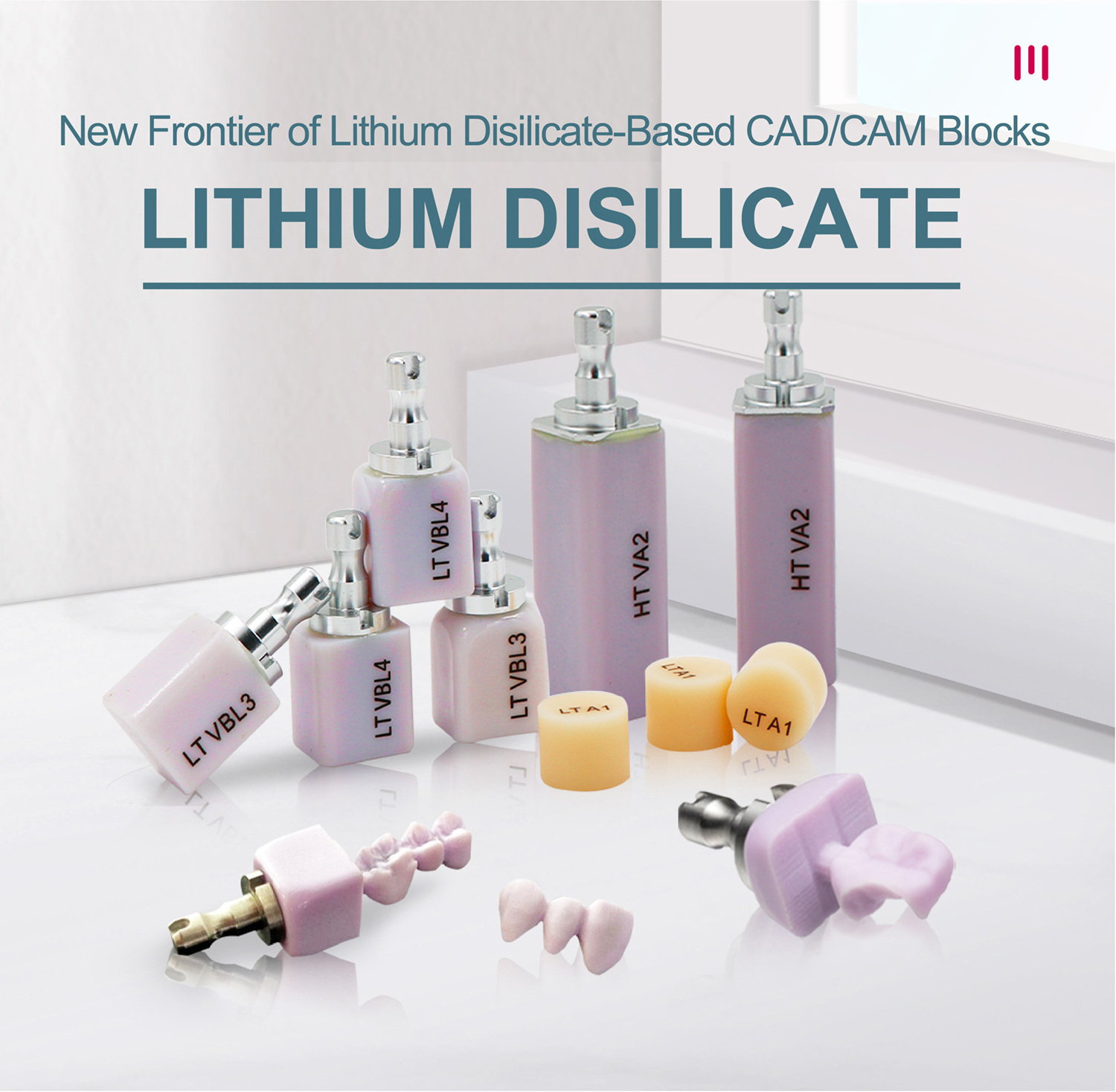

Glorious LT/HT CAD CAM System Dental Implants Material Emax Glass Ceramic Lithium Disilicate Block For Dental Lab

Get Latest Price

US$ 23

≥1 Sets

Quick Details

Warranty:

1 Year

After-sale Service:

Online technical support

Place of Origin:

Shandong, China

Model Number:

Emax

Product Details

Product Description

E.max CAD HT - The minimally invasive block:Given their high translucency which is similar to that of natural enamel, HT blocks are ideal for the fabrication of small restorations (e.g. inlays, onlays). Restorations made of HT blocks convince user with their true-to-nature chameleon effect and the exceptional adaptation to the remaining tooth structure.

E.max CAD LT - The versatile block:Given their low translucency which is similar to that of the natural dentin, LT blocks are ideal for the fabrication of larger restorations (e.g. posterior crowns). Restorations made from LT blocks convince users with their lifelike brightness and chroma. This prevents the incorporated restorations from greying.

E.max CAD MO - The classical block:Given their particular opacity, MO blocks are ideally suitable for the fabrication of frameworks on slightly discoloured preparations. They are primarily used in the dental laboratory.

Production Process

Advantages

Crystallization and Glaze

A porcelain furnace is used to crystallize the restoration to its final state.

Depending on the final aesthetic requirements of the restoration,an appropriate heating program should be chosen.Crystallization and glazing are achieved in two steps,displayed in the two charts below depending on the type of restoration.

Sintering program for crystallization only or crystallization together with glazing,Program 1 or program 2 is available.

One - step process

|

Crystallization only or crystallization together with glazing

|

|

|

|

|

|

|

||||||

|

Starting temp/℃

|

Dry time /mm:ss

|

Temp increasing rate/℃

|

Holding temp /℃

|

Holding time /℃

|

Vacuum start /℃

|

Vacuum finished /℃

|

||||||

|

400

|

00:30

|

40

|

840

|

07:00

|

550

|

840

|

||||||

Two - step process

|

Crystallization only or crystallization together with glazing

|

|

|

|

|

|

|

||||||

|

Starting temp/℃

|

Dry time /mm:ss

|

Temp increasing rate/℃

|

Holding temp /℃

|

Holding time /℃

|

Vacuum start /℃

|

Vacuum finished /℃

|

||||||

|

400

|

06:00

|

90/30*

|

820/840

|

00:10/07:00

|

550/820

|

820/840

|

||||||

Glzaing process

|

Glazing process

|

|

|

|

|

|

|

||||||

|

Starting temp/℃

|

Dry time /mm:ss

|

Temp increasing rate/℃

|

Holding temp /℃

|

Holding time /℃

|

Vacuum start /℃

|

Vacuum finished /℃

|

||||||

|

400

|

00:30

|

40

|

840

|

03:00

|

550

|

840

|

||||||

Feedback

Glorious has 8 years of experience in producing drainage consumables. In the spirit of responsibility for the customer, our company keeps tight follow-up with product quality, visits our customers periodically, adopts the suggestions from our customers, and offers the all-day, all-directional and top-grade market services. We have a professional after-sales team that will answer all your questions online for free. The technical and after-sale services are listed as follows:

1. Our company will provide services by phone, Whatsapp, Skype, e-mail, etc., please refer to the contact details.

2. Our company will implement the contract strictly; deliver the products to location specified by our customers in accordance with the mode of transportation.

3. Free return or replacement will be provided if defects result from quality failure of our product.

Contact person: You can reach us personally Monday to Saturday from 8 a.m. to 6 p.m.

Delivery

FAQ

1.Who are we?

We are based in Shandong, China, start from 2016, sell to Africa(30.00%), Domestic Market(20.00%), North America(20.00%), Eastern Europe(5.00%), South Asia(5.00%), Southern Europe (5.00%), Western Europe(5.00%), Mid East(5.00%), South

America(5.00%). There are total about 11-50 people in our office.

America(5.00%). There are total about 11-50 people in our office.

2.How can we guarantee quality?

Always a pre-production sample before mass production; Always final Inspection before shipment;

3.What can you buy from us?

Dental Consumable Materials, CAD/CAM Milling Machine, Dental 3D Scanner, Milling Burs, Dental Porcelain.

4.Why should you buy from us not from other suppliers?

The factory which we are cooperating is a State-owned enterprise and our company is the sole agent in north of China can do the OEM business.We are the zirconia powder manufacturer too. The Zirconia with excellent stability also with high cost performance.

5.What services can we provide?

5.What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, Express Delivery, AcceptedPayment. Currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF; Accepted Payment Type: T/T, MoneyGram, PayPal, Western Union, Cash;

Language Spoken:English,Chinese