NaN / 0

High accuracy factory sell digital LPG magnetostrictive fuel tank diesel level monitor automatic tank gauge

Get Latest Price

US$ 200

≥1 Sets

Quick Details

Grade:

DIY, Industrial

Warranty:

12 MONTHS

Place of Origin:

Shandong, China

Brand Name:

GUIHE

Product Details

Product Description

Automatic Tank Gauging System

Functions

| Display | English Language, Graph, Colored |

| Monitoring Capability | 8 tanks or 12 tanks |

| Method of Communication | RS-485 |

| Relay | With 2 relay |

| Print Function | User can print all kinds of reports |

| Network Function | Inquiring data in long-distance through internet |

| Explosion-proof Ringer | Avoiding the product spilled |

| Control the Oil Pump | Avoiding the product spilled and pump down |

| Automatic Gauge | Display product level, water level, temperature, volume, ullage .. |

| Interface | With one RS-232 serial interface communication ports |

Automatic Tank Gauging System

Automatic Tank Gauge (ATG) system consists of Magnetostrictive Probe and Smart Console, it is an electronic device, whose basic function is to monitor the fuel level in the tank. It can also tell the operator what is going on inside the tank. In other words, it gives us very important information like fuel level, volume and temperature, water level and volume, high and low fuel level warnings etc. There are different plans to satisfy different customers according to their effective demands.

Solution for choose:

1. SYW-A Probe (RS485 MODBUS protocol ) + others brand controller

2. SYW-A Probe (RS485 MODBUS protocol ) + others brand controller +Remote

3. SYW-A Probe + TCM-1 Console

4. SYW-A Probe + TCM-1 Console +PC software

5. SYW-A Probe + TCM-1 Console + Internet Remote (like Mobile APP)

6. SYW-A Probe + TCM-1 Console + Inter Remote Query

7. SYW-A Probe + TCM-1 Console + Dispenser (pump) center control software system (other brand)

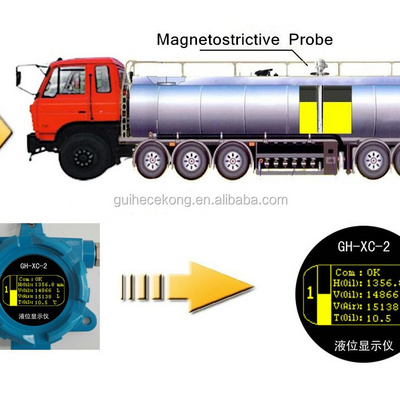

Magnetostrictive Probe

* The probe consist of :

Fully closed magnetostictive probe

Electronic pod using for data measuring and transforming

Floater made according to the product

* Features :

Safety : ExiaIIBT4(Intrinsically safe) issued by PCEC

Accuracy : level accuracy is ±0.3mm

Stability : strong anti-jamming ability

Efficiency : less than 1 second to test one tank

* Optional Features :

Density ball : Probe can add the density ball to measure the oil density automatically

* Probe Performance :

|

Item |

SYW -A |

|

Purpose |

To measure Product level, interface level and temperature .... |

|

Measuring Medium |

Gasoline, diesel, kerosene, diesel oil, ethanol, water, etc |

|

State of the Medium |

Liquid |

|

Explosion-Proof grade |

ExiaIIAT4 (Intrinsically safe) |

|

The range of pressure |

0.02Mpa~0.6Mpa |

|

Certificate |

PCEC Conformity Certificate of Explosion-proof |

|

Temperature range |

.-40℃-70℃ |

|

Product Level Accuracy |

±0.3mm |

|

Water Level Accuracy |

±0.3mm |

|

Temperature Accuracy |

±0.2℃ |

|

Height Resolution |

0.023mm |

|

Repeatability |

±0.1mm |

|

Temperature Effect |

Error<0.2mm |

|

Vibration Effect |

Error<0.5mm |

|

Lowest Product Inactive Zone |

2.5'' floater-180mm |

|

Lowest Water Inactive Zone |

2.5'' floater-25mm |

|

Measure range |

600~4000mm |

|

Communication Methods |

RS-485 |

|

Power supply mode |

.+24~26VDC |

|

Enclosure Ratings |

IP67 |

|

Probe Material |

1Cr18Ni9Ti |

|

Max communication distance |

1200m |

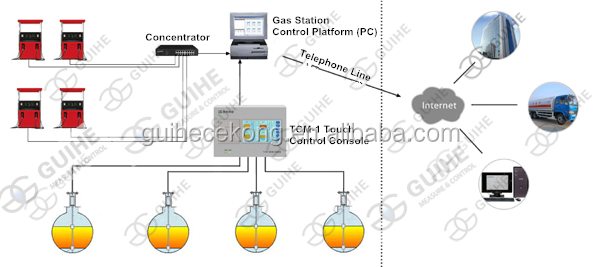

Touch Control Console

* It can monitor up to 1-12 tanks and monitor the delivery conditions, it also enjoys a static leak test function

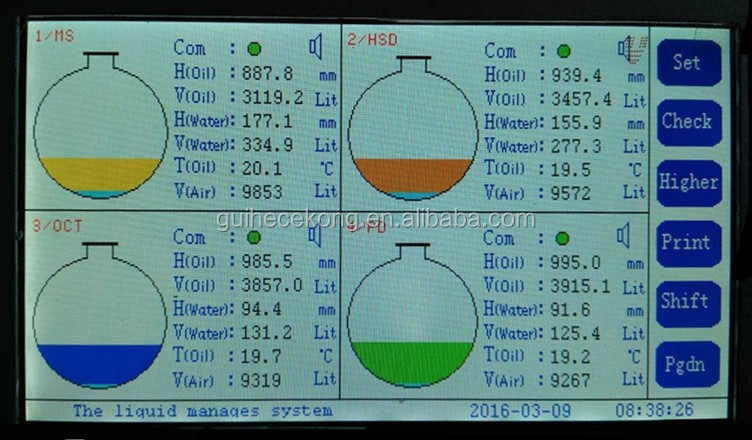

* It can display product level, water level, temperature, volume, ullage

* It enjoys a tank tilt compensation function

* It can display dynamically the change of product level and water level with graphics in proportion, it features a 7 inch colored touch-screen console panel, and each interface displays 4 graphics

* It features an audible and visual alarm function with front panel

* It comes with one RS-232 serial interface communication ports to connect with different brand Center Console or connect to PC software ,one RJ45 port for remote monitor

* It enjoys a record function, all information are stored in memory for future queries

* There is an embedded printer in it to print inventory reports, delivery reports, leak reports and shift reports

* It can calculate volume of product by multipoint, which can fully ensure the accuracy of volume of the product

* After connected with Center Console though internet, it can provide information in long-distance for manager to arrange the inventory

* It can monitor the oil pump according to the product level, which can avoid the product spilled and pump down

* It can connect with flow-meter to display delivery information constantly

Remote monitor detail

Total system

About installation

Workshop show :

Packaging & Shipping

Our Services

1. Delivery time is 3~7 days for sample and 15 working days for bulk order;

2. Strong production capacity and strict quality control system;

3. Your inquiry and problems related to our products or prices will be replied in 24 hours;

4. Well-trained and experienced staffs to answer all your inquires;

5. After-sale tracking service for all of our clients;

6. OEM is available; small quantities, mixed bulk orders are also welcome;

7. Payment: L/C, D/A, D/P, T/T, Paypal , Western Union, MoneyGram;

8. Delivery way: UPS, DHL, TNT, FEDEX, EMS, CHINA POST.

Hot Searches