NaN / 0

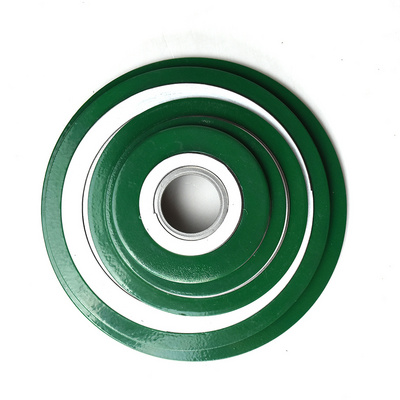

PTFE stainless steel spiral wound gasket

Get Latest Price

US$ 1.8

≥10 Pieces

US$ 1.5

≥100 Pieces

US$ 1.2

≥500 Pieces

US$ 0.8

≥1000 Pieces

Quick Details

Place of Origin:

Hebei, China

Brand Name:

HTong

Model Number:

many

Standard or Nonstandard:

Standard

Product Details

Metal winding gaskets (basic type) are made of high quality SUS304, SUS316 (V or W) metal strips and other alloy materials overlapping with graphite, asbestos, polytetrafluoroethylene and asbestos-free soft materials. The metal strips are fixed by spot welding at the beginning and at the end.

Characteristic

1. Wide operating range. It can withstand high temperature, high pressure and adapt to ultra-low temperature or vacuum conditions. By changing the material combination of gaskets, the problem of chemical corrosion of gaskets by various media can be solved.

2. Strong ability of stress compensation. In the position where temperature and pressure fluctuate frequently, the sealing performance is stable and reliable.

3. Good sealing performance.

4. The requirement for surface accuracy of flange seal contacted with gasket is not high.

5. Easy installation, low gasket pre-tightening pressure.

The metal winding gasket is made of V-shaped or W-shaped stainless steel strip and non-metallic filler, spirally wound and spot welding at the beginning and end. It has good compression resilience and is suitable for sealing parts with severe temperature and pressure alternation. It is a static sealing element at flange joints of pipes, valves, pumps, heat exchangers, towers, manholes and hand holes. It is widely used in petrochemical, mechanical, electric power, metallurgy, shipbuilding, medicine, atomic energy and astronautics. Types of metal wound gaskets:

Example of product name code applicable representation

Basic Type Metal Winding Pad JUNIO 2 00 Tenon Groove 304/PTFE

JUNIO 200 IR concave-convex surface 304/304/FG with inner ring metal winding pad

JUNIO 200 CR protrusion 304/ASB/CS with outer ring metal winding pad

JUNIO 200 IC 304/304/FG/CS with inner and outer ring metal winding pad

JUNIO 200 H heat exchanger 304/FG with one rib

Special-shaped metal winding cushion JUNIO 200 S special-shaped ellipse

If gaskets are used in heat exchangers, we generally recommend stainless steel wire inner rings with a diameter of 3.2mm. Narrow bands can be divided into two types: sticking type and cladding type. Material selection of metal winding gaskets: steel belt and inner and outer ring material, filling material of steel belt and inner and outer ring material, filling material of steel belt and inner and outer ring material, general thickness of mm and general thickness of mm of inner and outer ring material.

Name Code Name Code Name V-shaped Pad/Ring V-shaped Pad/Ring

Carbon steel CS carbon steel 3.2/2.04.5/3.04.8/3.05.5/4.07.5/5.0

Stainless steel 304 (L), 316 (L) 304 (L), 316 (L) stainless steel

Monel Monel Mon Monel

Nickel, Ti Ni, TiNi, TiNi, TiNi, Ti

Inco Nickel INC Inco Nickel INC Inco Nickel

Generally, the inner ring is made of the same steel strip to meet the requirements of medium and working conditions. The outer ring is made of the same material as the pipe and the corresponding equipment shell, and the carbon steel outer ring is more economical. Product standard of metal winding gaskets: We can produce according to ANSI B 16.20, MSS SP-44, API 605, DIN, JIS, JPI, BS 1560, JG/T, GB/T, HG, SH and other standards. Or the user specifies the requirements. If gaskets are used in heat exchangers with ribs, please provide specific drawings and specific orders. Specific material, standard, nominal diameter DN, pressure grade PN, or specific dimensions should be indicated: D1: inner ring diameter; D2: inner ring diameter; D3: outer ring diameter; D4: outer ring diameter writing method: D1 *D2 *D3 *D4 gasket default thickness is 4.5mm, ring is 3mm.

Material with inner and outer rings: OCr18N19SS304316316L Monel, pure titanium with outer rings, with inner rings, basic shape.

Graphite metal wound gasket service temperature - 200 - 850 Temperature and service pressure 0 - 20Mpa

Use temperature of asbestos metal wound gaskets - 200 - 500 C and use pressure 0 - 25 Mpa

Tetrafluoro metal wound gaskets service temperature - 200 - 260 C service pressure 0 - 10Mpa

The material of metal strip, soft filler, inner and outer positioning reinforcement rings of winding gaskets can be selected freely according to different media and operating conditions. Suitable temperature and pressure range performance of various soft fillers: test conditions and indicators of gasket compression and resilience performance

We have thousands molds

custom-made is available

Characteristic

1. Wide operating range. It can withstand high temperature, high pressure and adapt to ultra-low temperature or vacuum conditions. By changing the material combination of gaskets, the problem of chemical corrosion of gaskets by various media can be solved.

2. Strong ability of stress compensation. In the position where temperature and pressure fluctuate frequently, the sealing performance is stable and reliable.

3. Good sealing performance.

4. The requirement for surface accuracy of flange seal contacted with gasket is not high.

5. Easy installation, low gasket pre-tightening pressure.

The metal winding gasket is made of V-shaped or W-shaped stainless steel strip and non-metallic filler, spirally wound and spot welding at the beginning and end. It has good compression resilience and is suitable for sealing parts with severe temperature and pressure alternation. It is a static sealing element at flange joints of pipes, valves, pumps, heat exchangers, towers, manholes and hand holes. It is widely used in petrochemical, mechanical, electric power, metallurgy, shipbuilding, medicine, atomic energy and astronautics. Types of metal wound gaskets:

Example of product name code applicable representation

Basic Type Metal Winding Pad JUNIO 2 00 Tenon Groove 304/PTFE

JUNIO 200 IR concave-convex surface 304/304/FG with inner ring metal winding pad

JUNIO 200 CR protrusion 304/ASB/CS with outer ring metal winding pad

JUNIO 200 IC 304/304/FG/CS with inner and outer ring metal winding pad

JUNIO 200 H heat exchanger 304/FG with one rib

Special-shaped metal winding cushion JUNIO 200 S special-shaped ellipse

If gaskets are used in heat exchangers, we generally recommend stainless steel wire inner rings with a diameter of 3.2mm. Narrow bands can be divided into two types: sticking type and cladding type. Material selection of metal winding gaskets: steel belt and inner and outer ring material, filling material of steel belt and inner and outer ring material, filling material of steel belt and inner and outer ring material, general thickness of mm and general thickness of mm of inner and outer ring material.

Name Code Name Code Name V-shaped Pad/Ring V-shaped Pad/Ring

Carbon steel CS carbon steel 3.2/2.04.5/3.04.8/3.05.5/4.07.5/5.0

Stainless steel 304 (L), 316 (L) 304 (L), 316 (L) stainless steel

Monel Monel Mon Monel

Nickel, Ti Ni, TiNi, TiNi, TiNi, Ti

Inco Nickel INC Inco Nickel INC Inco Nickel

Generally, the inner ring is made of the same steel strip to meet the requirements of medium and working conditions. The outer ring is made of the same material as the pipe and the corresponding equipment shell, and the carbon steel outer ring is more economical. Product standard of metal winding gaskets: We can produce according to ANSI B 16.20, MSS SP-44, API 605, DIN, JIS, JPI, BS 1560, JG/T, GB/T, HG, SH and other standards. Or the user specifies the requirements. If gaskets are used in heat exchangers with ribs, please provide specific drawings and specific orders. Specific material, standard, nominal diameter DN, pressure grade PN, or specific dimensions should be indicated: D1: inner ring diameter; D2: inner ring diameter; D3: outer ring diameter; D4: outer ring diameter writing method: D1 *D2 *D3 *D4 gasket default thickness is 4.5mm, ring is 3mm.

Material with inner and outer rings: OCr18N19SS304316316L Monel, pure titanium with outer rings, with inner rings, basic shape.

Graphite metal wound gasket service temperature - 200 - 850 Temperature and service pressure 0 - 20Mpa

Use temperature of asbestos metal wound gaskets - 200 - 500 C and use pressure 0 - 25 Mpa

Tetrafluoro metal wound gaskets service temperature - 200 - 260 C service pressure 0 - 10Mpa

The material of metal strip, soft filler, inner and outer positioning reinforcement rings of winding gaskets can be selected freely according to different media and operating conditions. Suitable temperature and pressure range performance of various soft fillers: test conditions and indicators of gasket compression and resilience performance

We have thousands molds

custom-made is available

| 50×70×10 | 130×165×10.5 | 375×407×12 | 1480×1544×25 |

| 50×75×10 | 140×170×12 | 380×420×16 | 1500×1560×24 |

| 50×80×10 | 145×160×12 | 385×435×20 | 1600×1660×24 |

| 53×63×8 | 145×175×12 | 400×440×16 | 1550×1640×28 |

| 55×75×10 | 150×170×10 | 400×450×16 | 1680×1740×30 |

| 55×80×10 | 150×170×12 | 420×460×16 | 1740×1680×30 |

| 56×71×8 | 150×175×12 | 430×470×16 | 1800×1860×20 |

| 56×72×8 | 150×180×12 | 440×480×16 | 1800×1860×30 |

| 56×76×8 | 158.5×190 | 448×500×16 | 2000×2060×24 |

| 60×75 | 160×185 | 450×482×13 | 2100×2160×24 |

| 60×80×10 | 160×190×12 | 450×490×16 | 2300×2360×24 |

| 60×85×10 | 160×192×12 | 160×500×16 | 2440×2500×24 |

| 60×90×20 | 160×200× | 480×520×16 | - |

| 62×92×10 | 165×180×12 | 480×510×16 | - |

| 63×80×10 | 165×189×12 | 500×540×16 | - |

| 65×80×10 | 165×200×12 | 510×560×16 | - |

| 65×85×10 | 170×195×12 | 510×560×25 | - |

| 60×90×10 | 170×200×12 | 520×560×16 | - |

| 65×90×10 | 170×210 | 530×570×16 | - |

| 60×95×10 | 170×220×12 | 540×580×16 |

We can design and manufacture various rubber parts, custom-made is welcome

custom-made is welcome.

material: NBR, FKM, EPDM, silicon rubber are available.

size: hundreds

custom-made is welcome.

Tel: 0086 15933828740