NaN / 0

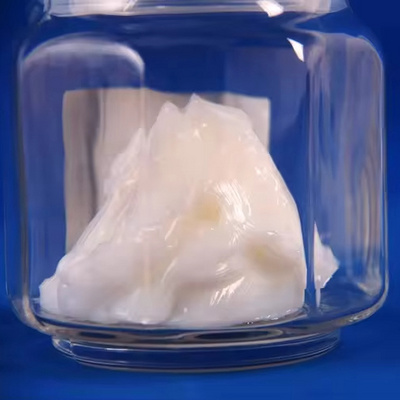

Multi Purpose Anti-seize Copper High Level Temperature Lubricating Grease

Get Latest Price

US$ 0.37

≥100 Pieces

Quick Details

Application:

Automotive Lubricant

Type:

Greases

Place of Origin:

Guangdong, China

Brand Name:

WBG

Product Details

Product Details

▲Good anti-seize performance at high temperature: Grease has high heat resistance. Under the environment higher than 330℃, the evaporation of base oil will increase. Copper powder, aluminum powder, nickel powder and other metal powder or molybdenum disulfide, Graphite and other high temperature resistant solid lubricant additives play a role in ensuring the long-term operation of the equipment. It also effectively prevents seize at extremely high temperatures and can withstand high temperatures of 1400°C.

▲Good anti-extreme pressure ability: reduce the wear of lubricating parts by 80% under high temperature and high load conditions.

▲Good rust and corrosion resistance: Effectively reduce the maintenance cost of lubricating parts by 60%.

▲Good sealing stability: It can fully fill the gaps between the screw and nut connecting seals, and improve the lubrication and sealing performance by 99%.

▲Good thread tightness: the pre-tightening force is not discrete, stress cracks and welding brittleness will not occur, and it can be disassembled without damage even after long-term operation at high temperatures.

▲Good anti-extreme pressure ability: reduce the wear of lubricating parts by 80% under high temperature and high load conditions.

▲Good rust and corrosion resistance: Effectively reduce the maintenance cost of lubricating parts by 60%.

▲Good sealing stability: It can fully fill the gaps between the screw and nut connecting seals, and improve the lubrication and sealing performance by 99%.

▲Good thread tightness: the pre-tightening force is not discrete, stress cracks and welding brittleness will not occur, and it can be disassembled without damage even after long-term operation at high temperatures.

Our Advantages

Certifications

Hot Searches