NaN / 0

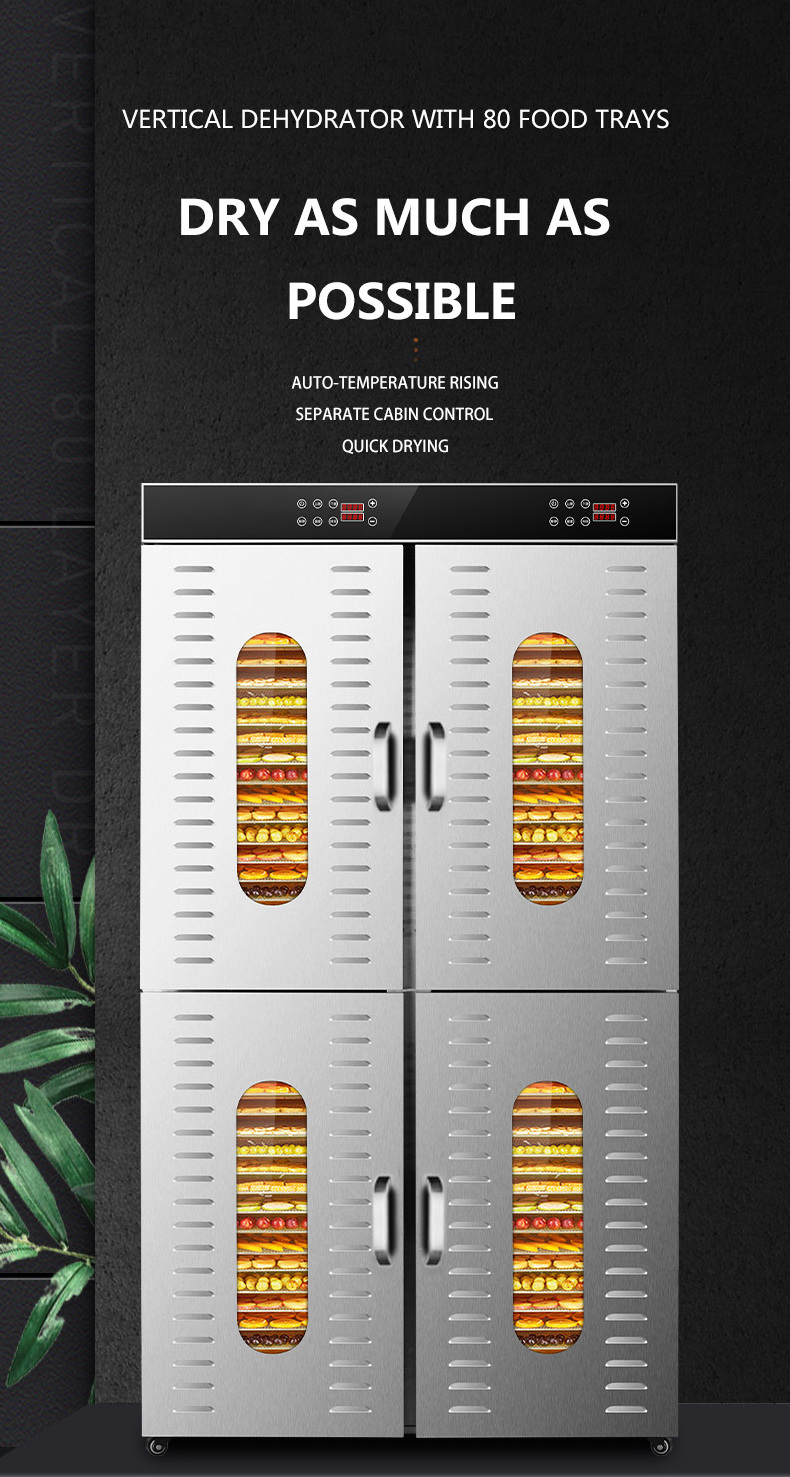

industrial food dryer / industrial food drying machine / industrial fruit dehydrator

Get Latest Price

US$ 755

≥1 Pieces

US$ 720

≥10 Pieces

US$ 690

≥16 Pieces

US$ 675

≥42 Pieces

Quick Details

Core Components:

Heating elements

Place of Origin:

Guangdong, China

Brand Name:

Neutraul

Type:

new

Product Details

Product Description

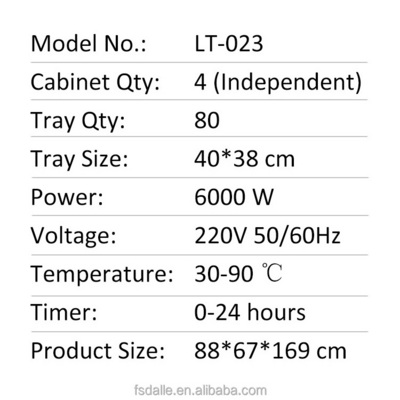

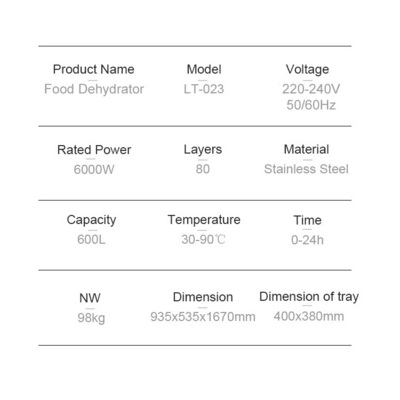

| Power | 6000W(Integrated power consumption:4800W per hour) |

| Product Size | 53.5L*93.5W*167.5H(CM) - Largest drying capacity in China market |

| Quantity Of Trays | 80 trays (Upper and Lower rack gap:35mm) |

| Drying Tray Size | 40*38CM |

| Voltage | 220V/50Hz or 60 Hz |

| Timer | 0-24 hours adjustable |

| Temperature Range | 30-90℃ |

| Cabinets Qty and Type | 4 Cabinets with independent control |

| Operating noise | 45-50decibels |

| Warranty | 1 years (heating element for 3 years) |

| Other Features |

1.Digital control with touch control panel 2.Single layer outershell 3.Aluminum Door handle 4.With additional 4pcs crumb trays |

Packaging & Shipping

package size:105cm*65cm*187cm (1PCS/CTN)

N.W/G.W:140KG/180KG(1PCS/CTN)

CTN:(W)105 X (H)65X (D)187mm

Our Services

Warranty:1 years (heating element for 3 years)

The major assistance Dalle will provide includes:

Helping customer to purchase complete equipment, including large injection moulding machine and punching machine.

- Providing customer with related mould, including plastic and hardware mould.

- Providing customer with related parts, gathering it and loading together.

- Dispatching engineers to Cusotmer’s factory and help them to plan production place, install the equipment and mould, training their worker and flow line production.

- Providing customer with improvement scheme of production, Solving all kind of urgent situation.

- Cooperating with customers and developing new rice cooker model together.

ODM project process

1.Communication Requirements: Customer provide sample or design paper with details requirements.

2.factory quoting: quotation is passed by customer and factory provide die design.

3.making prototype: within 5-7days, provide the 1:1 mock-up

4.confirmation of prototype: customer confirm the 1:1 mock-up after several adjustment

5.Opening mould. Produce the mould according to the confirmation of 1:1 mock-up,takes around 1-2months

6.testing mould. Try the mould repeatedly and make sure there is no flaws on finished products.

7.Trial production. Small mass production after passing the mould testing and do fully product test

8.Mass production. Start mass production after passing the trial production, and customer pay the deposit.

9.Inpection&delivery. Delivery within 4 weeks, customer arrange the balance payment.

Hot Searches