NaN / 0

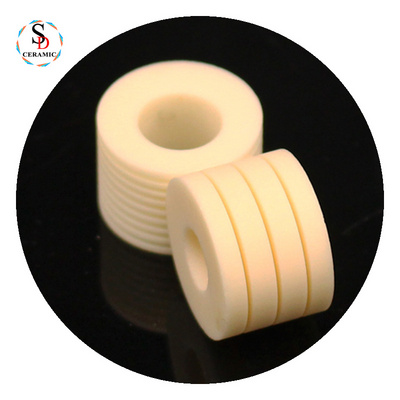

Industrial Ceramics/Alumina Al2O3 Ceramic Seal Rings

Get Latest Price

US$ 3

≥10 Pieces

US$ 1.5

≥100 Pieces

US$ 1

≥1000 Pieces

Quick Details

Material:

Alumina Ceramic

Place of Origin:

Fujian, China

Model Number:

N/A

Brand Name:

MASCERA

Product Details

Product Description

|

Product Name

|

Industrial Ceramics/Alumina Al2O3 Ceramic Seal Rings

|

|

Material

|

99% Alumina Ceramics/Al2O3 Ceramics

|

|

Color

|

Ivory

|

|

Surface Finishing

|

Fine Machining

|

|

Customized Manufacturing

|

Available

|

|

Product Feature

|

High wear resistance/High mechanical strength

|

|

Usage

|

Ceramic wear resistant parts for machinery

|

Alumina Ceramic

is the most widely used technical ceramic materials.It has high wear resistance, high mechanical strength, high temperature resistance, good thermal shock resistance, excellent electrical insulation. It is usually used for electrical insulators, wear resistant parts, ceramic parts for high temperature furnace etc.

Alumina Ceramic can be made by different purities like 95%, 96%, 99%, 99.5%, 99.7% etc, their properties will have little difference accordingly.

Typical properties

●Good strength and stiffness

●Good hardness and wear resistance

●Good corrosion resistance

●High thermal conductivity

●High temperature resistance

●Electrical insulation

●Low dielectric constant

Application examples

●Mechanical seal rings

●Plungers or pistons for valves

●Electronic substrates

●High temperature thermocouple tubes

●Textile eyelets or guides

●Electrical insulators

●Wear resistant nozzles

●Ceramic parts for high temperature furnace

|

Material

|

95% Al

2

O

3

|

96% Al

2

O

3

|

99% Al

2

O

3

|

99.5% Al

2

O

3

|

99.7% Al

2

O

3

|

|

Color

|

White/Pink

|

White

|

Ivory

|

Ivory

|

Ivory

|

|

Density (g/cm

3

)

|

3.65

|

3.72

|

3.88

|

3.90

|

3.92

|

|

Water Absorption (%)

|

0

|

0

|

0

|

0

|

0

|

|

Moh's Hardness

|

9

|

9

|

9

|

9

|

9

|

|

Flexural Strength (Mpa) (25℃)

|

352

|

358

|

364

|

379

|

375

|

|

Compressive Strength (Mpa) (25℃)

|

2000

|

2068

|

2500

|

2600

|

2500

|

|

Thermal Conductivity (W/m.k) (25℃)

|

18-25

|

≥24

|

27

|

30

|

30

|

|

Thermal Expansion Coefficient

(25-1000℃)(10-6mm/℃) |

8

|

8

|

8

|

8

|

8

|

|

Therma Shock Resistance △T(℃)

|

220

|

220

|

180-200

|

180-200

|

180-200

|

|

Max. Working Temperature (℃)

|

1500

|

1650

|

1700

|

1750

|

1750

|

|

Dielectric Strength (kv/mm)

|

16

|

17.2

|

20

|

22

|

22

|

|

Electrical Resistivity (Ω.cm) (25℃)

|

10

14

|

10

14

|

10

14

|

10

14

|

10

14

|

|

Dielectric Constant

(@1MHz, 25℃)

|

9

|

9

|

9.7

|

9.7

|

9.8

|

|

Dielectric Loss (tan delta)

(@1MHz, 25℃) |

0.0004

|

0.0002

|

0.0001

|

0.0001

|

0.0001

|

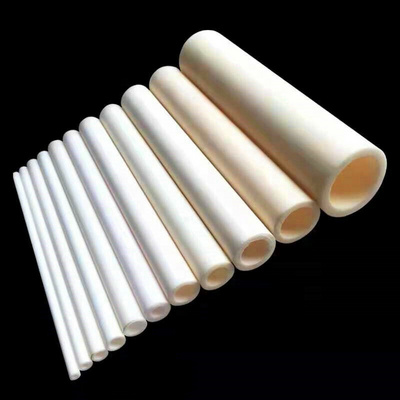

Products Show

Package&Shipment

Company Introduction

XIAMEN MASCERA TECHNOLOGY CO., LTD.

is a China supplier which specialized in R&D and custom manufacturing of technical ceramic components. We provide a broad range of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride ceramic, silicon carbide ceramic, boron nitride ceramic and aluminum nitride ceramic.

We have completed production lines for molding, sintering, high precision machining, quality inspection of technical ceramic components. Our products are in conformity with ISO9001:2015 quality management system and we are capable to deliver ceramic components of fully dense, accurate size and surface finish control, prompt lead time.

Since our foundation, Mascera has committed to providing ceramic components of highest quality and has built faithful partnership with our customers. Currently, our products have been exported to more than 30 countries and widely applied in industries like machinery, automotive, chemistry, medical, energy, electronic, semiconductor, aerospace, telecommunication etc.

We have completed production lines for molding, sintering, high precision machining, quality inspection of technical ceramic components. Our products are in conformity with ISO9001:2015 quality management system and we are capable to deliver ceramic components of fully dense, accurate size and surface finish control, prompt lead time.

Since our foundation, Mascera has committed to providing ceramic components of highest quality and has built faithful partnership with our customers. Currently, our products have been exported to more than 30 countries and widely applied in industries like machinery, automotive, chemistry, medical, energy, electronic, semiconductor, aerospace, telecommunication etc.

FAQ

Q1: What is MOQ for production?

A: MOQ will differ in material, size, machining difficulty, we will let you know MOQ for each part when inquiry.

Q2: Can i get a sample for test?

A: For ceramic parts we have in stock, we can provide free sample if goods value is not high; for ceramic parts which is newly developed, mold cost or sample cost will be needed.

Q3. Can you produce according to the samples or drawings?

A: Yes. most of our ceramic parts are customized, we have rich experience in tailor-made parts. We have capability to control the parts in required size accuracy and surface finish

Q4. How can i pay to you?

A: We accept payment of T/T, credit card, Western Union, Paypal.Payment terms is 50% payment in advance and 50% before shipment.

Q5. Can i get a replacement for damaged or defected products?

A: Yes, we will remake new products for you when damage or defect are found, if you could not wait for extra time, we will refund to you or issue a credit to use in future orders.

A: MOQ will differ in material, size, machining difficulty, we will let you know MOQ for each part when inquiry.

Q2: Can i get a sample for test?

A: For ceramic parts we have in stock, we can provide free sample if goods value is not high; for ceramic parts which is newly developed, mold cost or sample cost will be needed.

Q3. Can you produce according to the samples or drawings?

A: Yes. most of our ceramic parts are customized, we have rich experience in tailor-made parts. We have capability to control the parts in required size accuracy and surface finish

Q4. How can i pay to you?

A: We accept payment of T/T, credit card, Western Union, Paypal.Payment terms is 50% payment in advance and 50% before shipment.

Q5. Can i get a replacement for damaged or defected products?

A: Yes, we will remake new products for you when damage or defect are found, if you could not wait for extra time, we will refund to you or issue a credit to use in future orders.

Hot Searches