NaN / 0

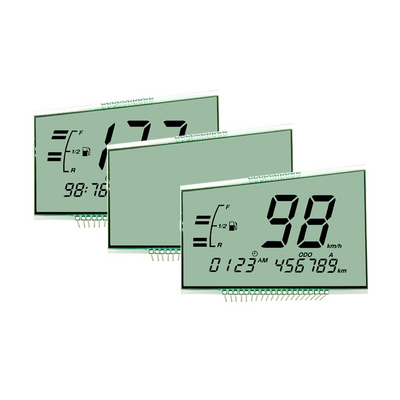

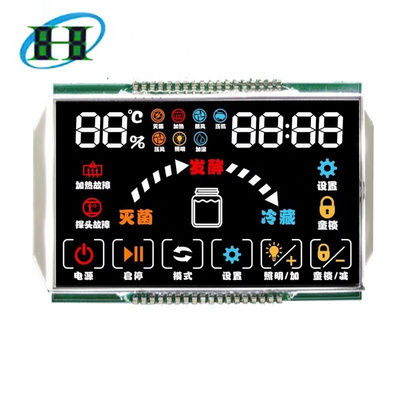

custom LCD 7 segment LCD display in Display Modules

Get Latest Price

US$ 0.1

≥1 Pieces

Quick Details

Type:

TN/HTN/STN/FSTN, STN

Display Size:

Custom

Supplier Type:

Original manufacturer/ODM

Place of Origin:

China

Product Details

Product Description

Custom LCD Form

1,LCD Outline Dimension

:

Front glass dimension:___________ mm Rear glass dimension: _____________ mm

Front glass thickness: ___________ mm Rear glass thickness: _______________mm

View Area: ___________ mm

2,Connector Type

( )Zebra ( )Heat Seal ( )Pin ( )Right Pin ( )Bend Pin

( )Front Pin ( ) Rear Pin ( )Other Pin: ____________

( )Pin Number: ______________ ( )Pin Pitch mm

3, LCD Display Type

A,( )TN ( )HTN ( )Y-G STN ( )Gray STN ( )Blue STN ( )FSTN ( )Other:__________

B,( )Reflective ( )Transflective ( )Transmissive

C,( )Positive ( )Negative

D, Special Requirement :_______________

4,Driving Method:

A,( )Driving Voltage: _____________V

B,( )Static ( )Mux: ____/____ Duty ____/____ Bias;

C,Frequency:____________ Hz

6,Special Requirement for Front Polarizer

( ) UV Protection ( ) Anti-glare ( )Color :___________ ( ) Other:___________

8,Special Techniques

( ) Printing Position ___________ Color:___________

( ) Corner cutting ( ) Chamfer ( )Others_____________

9, Package Requirement: ________________________________

10,Other Special Requirement: ________________________________

Remarks:

OEM/ODM is acceptable. We can supply all kinds of LCM products on the basic of customers’ design.

Procedures of Customization:

1. Customers offer the specifications of LCM, such as outline dimension of LCD, LCD type, display mode, operating voltage,

operating temperature and so on.

2. Technical Department make logic lay-out drawing on the receipt of customers’ requirements.

3. Customers confirm the logic lay-out drawing.

4. Opening mode, manufacture sample.

Front glass dimension:___________ mm Rear glass dimension: _____________ mm

Front glass thickness: ___________ mm Rear glass thickness: _______________mm

View Area: ___________ mm

2,Connector Type

( )Zebra ( )Heat Seal ( )Pin ( )Right Pin ( )Bend Pin

( )Front Pin ( ) Rear Pin ( )Other Pin: ____________

( )Pin Number: ______________ ( )Pin Pitch mm

3, LCD Display Type

A,( )TN ( )HTN ( )Y-G STN ( )Gray STN ( )Blue STN ( )FSTN ( )Other:__________

B,( )Reflective ( )Transflective ( )Transmissive

C,( )Positive ( )Negative

D, Special Requirement :_______________

4,Driving Method:

A,( )Driving Voltage: _____________V

B,( )Static ( )Mux: ____/____ Duty ____/____ Bias;

C,Frequency:____________ Hz

5,View Direction:

( ) 6 O’clock ( ) 12 O’clock ( ) 3 O’clock ( ) 9 O’clock ( ) Other:

6,Special Requirement for Front Polarizer

( ) UV Protection ( ) Anti-glare ( )Color :___________ ( ) Other:___________

7,Temperature Range:

A,Operating Temperature:__________°C to _________°C

B,Storage Temperature:_________°C to __________°C

A,Operating Temperature:__________°C to _________°C

B,Storage Temperature:_________°C to __________°C

8,Special Techniques

( ) Printing Position ___________ Color:___________

( ) Corner cutting ( ) Chamfer ( )Others_____________

9, Package Requirement: ________________________________

10,Other Special Requirement: ________________________________

Remarks:

OEM/ODM is acceptable. We can supply all kinds of LCM products on the basic of customers’ design.

Procedures of Customization:

1. Customers offer the specifications of LCM, such as outline dimension of LCD, LCD type, display mode, operating voltage,

operating temperature and so on.

2. Technical Department make logic lay-out drawing on the receipt of customers’ requirements.

3. Customers confirm the logic lay-out drawing.

4. Opening mode, manufacture sample.

Details Images