NaN / 0

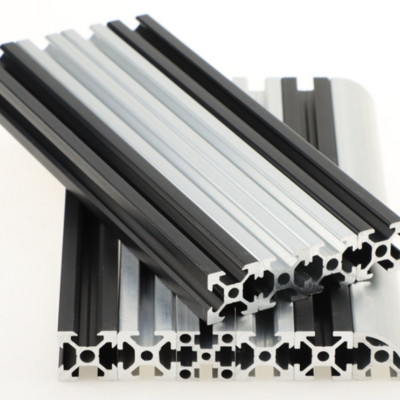

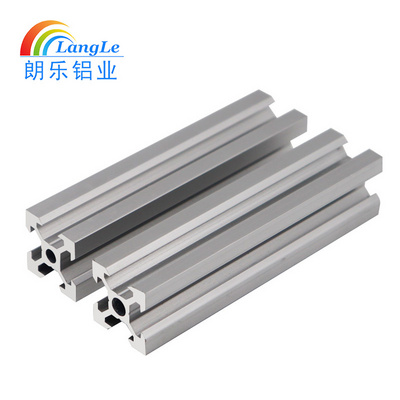

Langle aluminum factory 6063 silver black anodizing t slot aluminium extrusion 2040 v slot for linear rail 3D printer frame

Get Latest Price

US$ 4.5

≥1 Kilograms

Quick Details

Grade:

6000 Series

Tolerance:

±1%

Place of Origin:

Hunan, China

Model Number:

LE--6-2040

Product Details

Product Description

6063 silver black anodizing t slot aluminium extrusion 2040 v slot for linear rail 3D printer frame

We can offer you full set of types of aluminium extrusion, fasteners and aluminum profile accessories. Please tell me your

detailed requirements, we will quote a best prices to you.

While due page limitation, please come to me for our google online catalog to checking the details and select your needed items and specifications.

detailed requirements, we will quote a best prices to you.

While due page limitation, please come to me for our google online catalog to checking the details and select your needed items and specifications.

|

Application

|

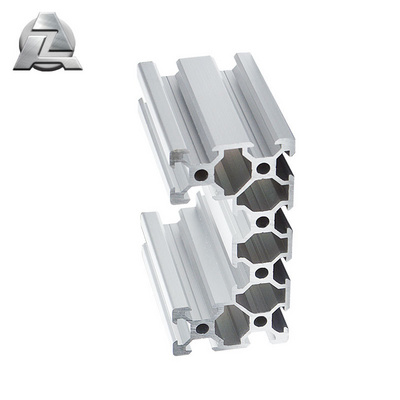

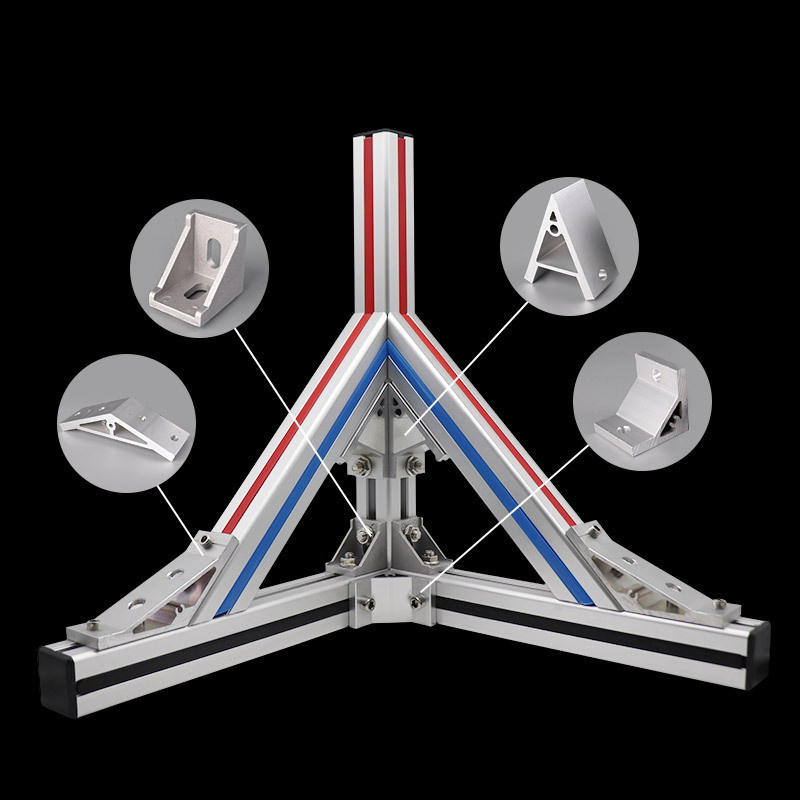

Best choice for simulator4040/4080/40120/40160

|

|

Aluminum profile Slot width

|

8MM 6mm or 10mm

|

|

Color

|

Natural silver anodised, black, can be customised.

|

|

Surface

|

Mill finish, Anodizeding, Sand Blasting, Powder coating, etc.

|

|

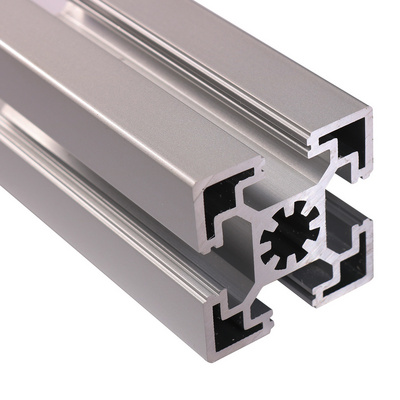

Deep processing

|

Cutting, Drilling, Treading, Bending, etc.

|

|

Application

|

Building & Construction, Industry, Machinery, Transportation,

Electrical & Energy, Machinery, Radial profiles for LED cooling, Non-standard Automation, Structure Framing, etc |

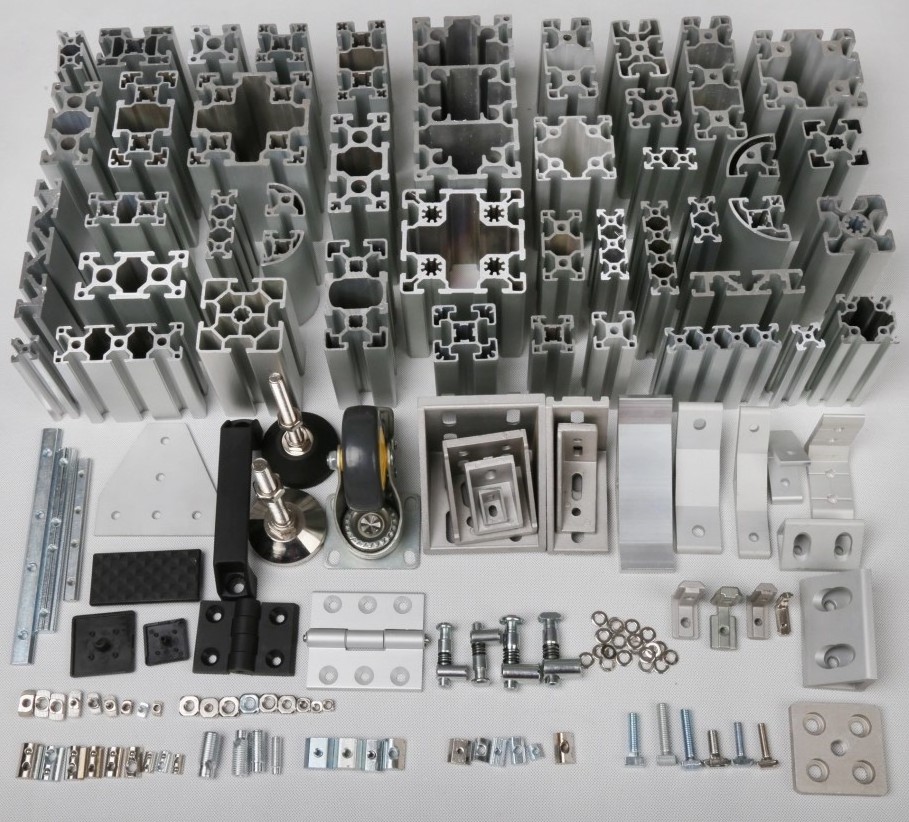

Detailed Images

Easy installations and all kinds of accessories for choose

Q:

How to choose the suitable aluminium profile to your design?

A:

Your goal as a designer is to come up with the design that best meets the requirements of the project. We would like to show you the quick guide with the four key points you need to consider when designing with aluminium extrusions. Understanding these basics will help you identify ways to reduce weight, add functionalities, simplify assembly, and minimize costs.

1. Designing with the right wall thickness

2. Rounded shapes will improve your design

3. Enhance your products with decoration

4. Achieving cost-efficient production

If you are interested in learning more about using aluminium in your product design, then please contact LangLe and we will put you in touch with the right expert.

1. Designing with the right wall thickness

2. Rounded shapes will improve your design

3. Enhance your products with decoration

4. Achieving cost-efficient production

If you are interested in learning more about using aluminium in your product design, then please contact LangLe and we will put you in touch with the right expert.

Advantage of Aluminum Extrusion

Aluminum in general, and aluminum extrusions in particular, offer a number of benefits relative to alternative materials and

processes. Aluminium extrusion is often the most viable solution that meets the specific manufacturing needs of design

flexibility, cost savings, product performance, and shorting design and assembling time.

The Advantage extrusion aluminum profile are included Lightweight, Strong, High in strength-to-weight material,Resilient,

Corrosion resistant, Excellent thermal conductors, Non-sparking, Excellent electrical conductors, Non-magnetic, Noncombustible & Nontoxic, Reflective, Seamless, Easily tailored, Quick-to-market, Easy to fabricate & assemble, Sustainable.

LangLe can help you choose the appropriate alloy and design the optimum extrusion profile for your project and budgetary

requirement, and associated accessories are available as well to save your time to resource it.

Aluminum in general, and aluminum extrusions in particular, offer a number of benefits relative to alternative materials and

processes. Aluminium extrusion is often the most viable solution that meets the specific manufacturing needs of design

flexibility, cost savings, product performance, and shorting design and assembling time.

The Advantage extrusion aluminum profile are included Lightweight, Strong, High in strength-to-weight material,Resilient,

Corrosion resistant, Excellent thermal conductors, Non-sparking, Excellent electrical conductors, Non-magnetic, Noncombustible & Nontoxic, Reflective, Seamless, Easily tailored, Quick-to-market, Easy to fabricate & assemble, Sustainable.

LangLe can help you choose the appropriate alloy and design the optimum extrusion profile for your project and budgetary

requirement, and associated accessories are available as well to save your time to resource it.

Customer's Reviews

Certificate

Related Products

Company Introduction

1. Rich experiences in industrial Aluminium Profile Application for Automation (15 years);

2. Mass available stock for a fast shipping to whole the world;

3. NO MOQ, even 0.5 meter can be acceptable;

4. Supply both aluminium profiles & related accessories to save your time on resourcing;

5. Welcome your CUSTOMIZED design, OEM acceptable;

6. Offer professional services from tooling design, extrusion production, assembling, cutting, drill threading till packaging.

NEVER worry about quality and deadline.

2. Mass available stock for a fast shipping to whole the world;

3. NO MOQ, even 0.5 meter can be acceptable;

4. Supply both aluminium profiles & related accessories to save your time on resourcing;

5. Welcome your CUSTOMIZED design, OEM acceptable;

6. Offer professional services from tooling design, extrusion production, assembling, cutting, drill threading till packaging.

NEVER worry about quality and deadline.

Packing&Shipping

FAQ

Q1: Are you a trading company or factory?

A: we are factory and has over 10 years experience for aluminium profile area.

Q2: Can you Send me a sample?

A: Yes, we can send you samples, samples are free and freight is on your side.

Q3: Do you have any MOQ limit for order?

A: Low MOQ, 1pc for sample checking is available.

Q4: What's the production time for new moulds and mass production?

A: 7~10 days to open the new moulds, mass production takes around 20~25days for one 20GP, 25~30days for one 40HQ, can process

urgently if needed.

Q5: How about the length for the profile?

A: Any custom-tailed lengths available. Max length of profiles are 6.02 meter longs.

Q6: Do you have accessories for the profile?

A: We are able to supply full accessories for the profile.

Q7: What is the payment terms?

A: Telegraphic Transfer(T/T) and Letter of Credit (L/C) are acceptable.

A: we are factory and has over 10 years experience for aluminium profile area.

Q2: Can you Send me a sample?

A: Yes, we can send you samples, samples are free and freight is on your side.

Q3: Do you have any MOQ limit for order?

A: Low MOQ, 1pc for sample checking is available.

Q4: What's the production time for new moulds and mass production?

A: 7~10 days to open the new moulds, mass production takes around 20~25days for one 20GP, 25~30days for one 40HQ, can process

urgently if needed.

Q5: How about the length for the profile?

A: Any custom-tailed lengths available. Max length of profiles are 6.02 meter longs.

Q6: Do you have accessories for the profile?

A: We are able to supply full accessories for the profile.

Q7: What is the payment terms?

A: Telegraphic Transfer(T/T) and Letter of Credit (L/C) are acceptable.

Hot Searches