NaN / 0

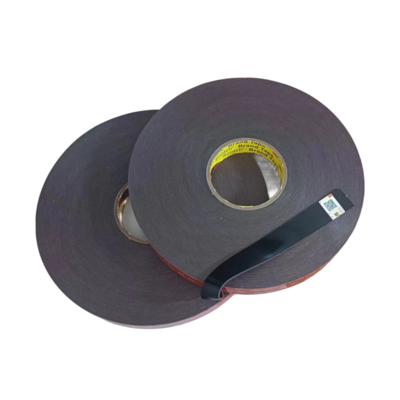

3M VHB Acrylic Foam Tape 5611 / 5611A-GP, Gray, 1.1mm Thick

Get Latest Price

US$ 0.15

≥1000 Pieces

Quick Details

Adhesive:

Acrylic

Adhesive Side:

Double Sided

Adhesive Type:

Pressure Sensitive

Design Printing:

No printing

Product Details

Product Description:

3M VHB Acrylic Foam Tapes 5611N-GF, 5611N-GP and 5611N-WP are double coated pressure sensitive adhesive tapes for bonding metals and other high surface energy materials. They have excellent temperature resistance and can be used to bond metal parts prior to paint processing.

Construction:

| Adhesive: | General Purpose Acrylic | ||

| Adhesive Carrier: | Acrylic Foam (Close cell) | ||

| Density: | 800 kg/m³ | ||

| Tape Number | Color | Thickness | Liner |

| 5611N-GF | Gray | 1.10 | Red PE Film |

| 5611N-GP | Gray | 1.10 | PEK Paper |

| 5611N-WP | Gray | 1.10 | PEK Paper |

Temperature Resistance:

Short Term:(minutes, hours) 200°F (93°C)

Long Term:(days, hours) 158°F (70°C)

Shelf Life:

24 months from date of manufacturing by 3M when stored in the original carton at 21°C (70°F) & 50 % Relative Humidity

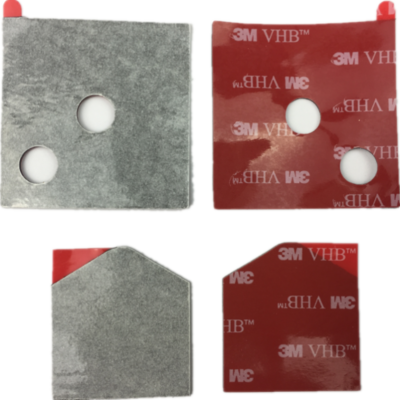

Pls contact us with the Tape's width or the outline dimensional drawings that you want to slite or die cut.

Pls contact us with the Tape's width or the outline dimensional drawings that you want to slite or die cut.

The benefit of using 3M VHB Tape:

- No holes to drill, no riveting, no liquid adhesives to cure, no weld distortion, no clean up

- Prevents corrosion by separating dissimilar metals.

- Is invisible and eliminates unsightly rivets, spot welds, screw-heads or nuts and bolts.

- Meets a wide range of holding requirements for tough applications involving glass, metals,woods, composites and many plastics.

- Damps vibration and reduces noise.

- Resists solvents and salt water. Seals and bonds even in extreme environments.

- Can compensate for thermal expansion and contraction of bonded parts.

- Distributes stress. Excellent for thin materials.

- Fast, clean and simple to apply. Reduces assembly costs.

How 3M VHB Tape work

The exceptional performance of these tapes comes from the properties of the acrylic core. The core has the dual properties of behaving like a very viscous liquid and an elastic solid. This property is known as viscoelasticity. The “visco” properties allow the adhesive to flow into the microscopic irregularities of the surface to form very strong bonds. The elastic properties allow these tapes to absorb dynamic loads, accommodate differential expansion between surfaces and help distribute loads over the greatest possible area. The elastic properties are maintained

between -40C and 90C.

Hot Searches