zhongyilong machine provide you with a complete set of solutions forThe Automatic Bottle Blowing production line

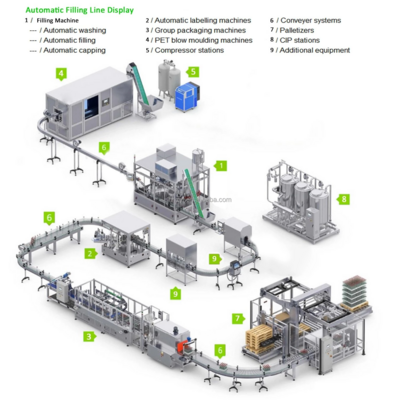

Turnkey/complete water production line includes :

1. Bottle blowing system make PET plastic bottles ( Semi automatic / Fully automatic )

2. Water treatment system purify water (Sand filter,carbon filter,RO/UF ,Ozone sterilizer,UV sterilizer and etc.)

3. Air conveyor for empty bottle loading

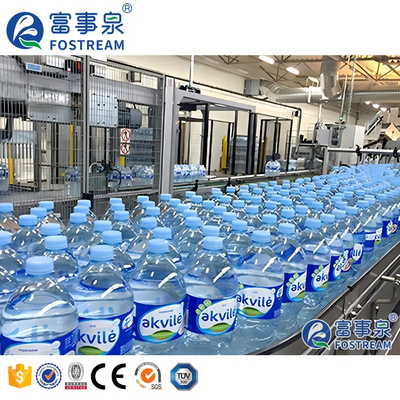

4. Rinser-filler-capper 3 in 1 monoblock

5. Cap loader load caps

6. Code printer (Ink-jet printer/ laser-jet printer)

7. Labeling machine ( PVC sleelve labeling machine/OPP hot melt glue labeling machine/Self-adheisive labeling machine )

8. End packaging ( PE shrink wrapping machine / Carton packing machine )